Tungsten type - aws color code, Importance of tungsten geometry – Arc Machines 307 User Manual

Page 149

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096 Chapter 15. Page 2.

Rev. A

tains a sharper tip and exhibits substantially longer

lifetime than other types and has excellent arc ignition

characteristics. Ceriated tungsten is non-radioactive.

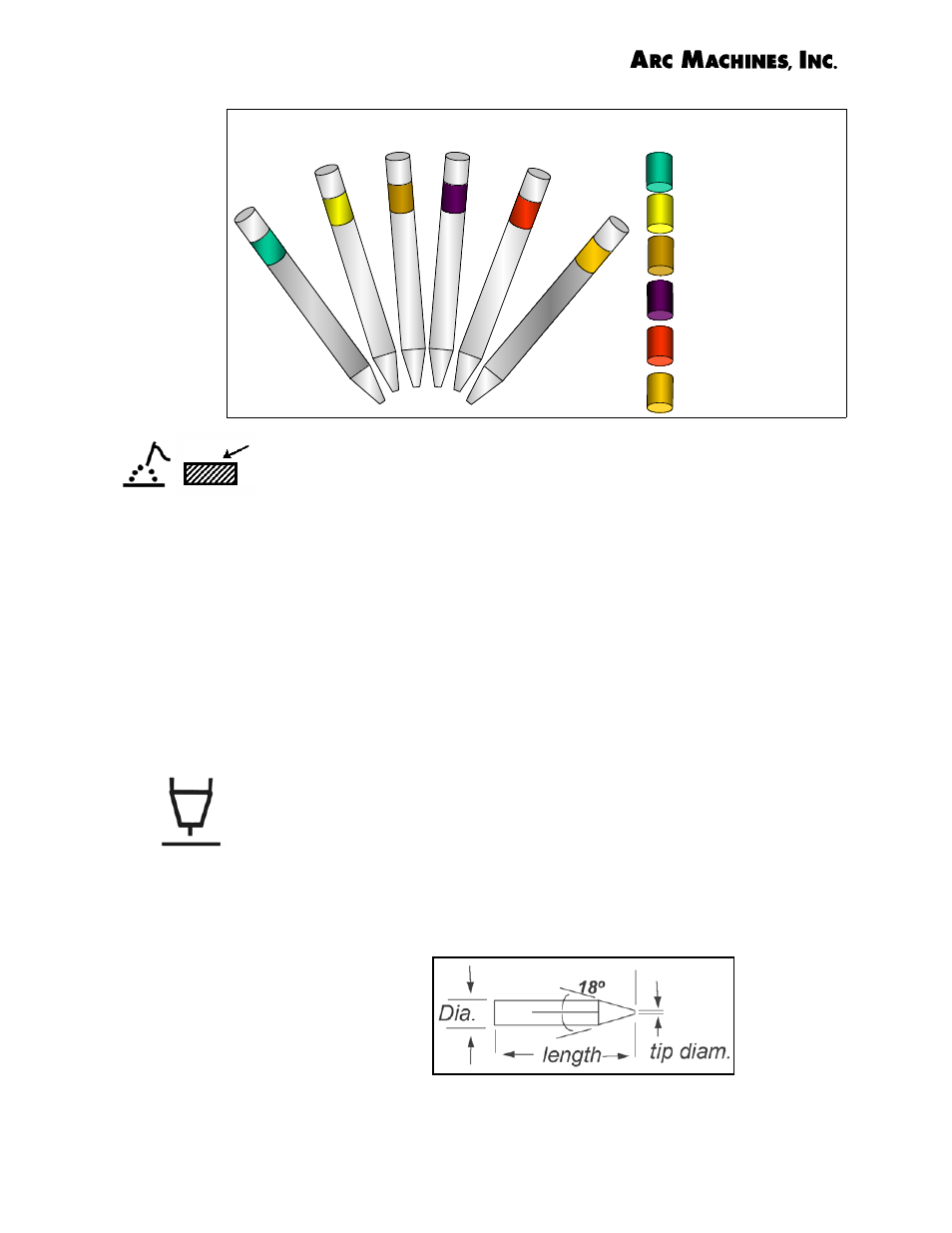

Tungsten is supplied as rods to be cut and machined into

electrodes. The unprocessed rods are color-coded as to

type: green for pure tungsten, orange for 2% ceriated,

red for 2% thoriated, etc. according to AWS Specification

A5.12/A5.12M as shown in the figure on this page. The

ISO International Standard 6848 has a comparable

tungsten type identification system.

Importance of Tungsten Geometry

Electrodes with a ground finish are dimensionally more

uniform. A smooth finish is always preferable to rough or

inconsistent finish, since consistency in electrode geome-

try is essential for consistent weld results. Electrons

emitted from the tip (DCEN) transfer heat from the tung-

sten tip to the weld. A finer tip permits the current den-

sity to be maintained at a very high level but may result

in shorter tungsten life. For orbital tube or pipe welding,

it is important for the electrode tip to be machine ground

to assure repeatability of the tungsten geometry and

thus, the welds.

2% Ce

TUNGSTEN

GEOMETRY

Tungsten Dimensions that are con-

trolled for orbital welding

Pure Tungsten

1.5% Lanthanated

2% Ceriated

Zirconiated

2% Thoriated

1% Thoriated

Tungsten Type - AWS color code

Tungsten length

determines the

Arc Gap

W