Arc Machines 307 User Manual

Page 142

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096 Chapter 13. Page 9

Rev. A

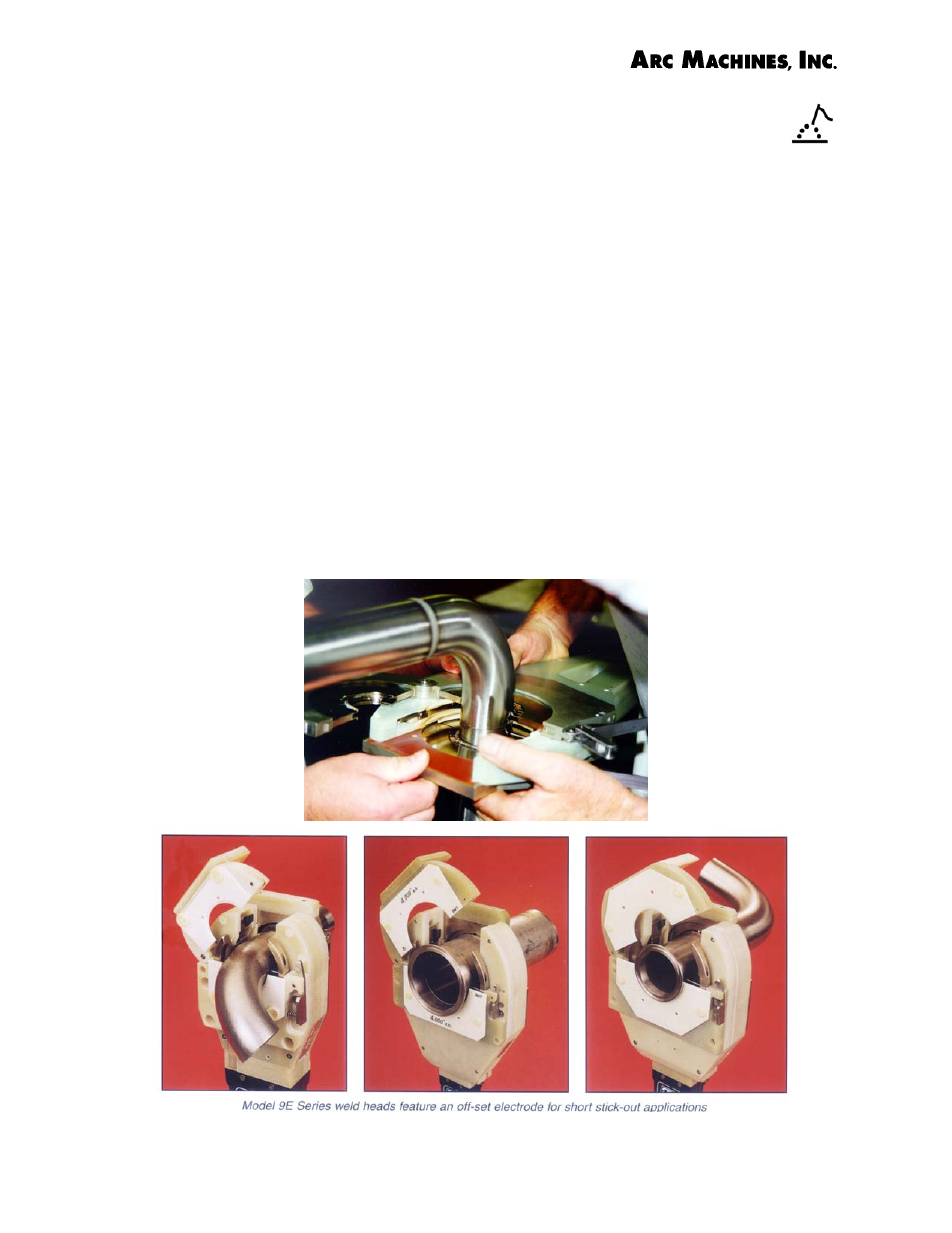

Tungsten Extenders - E type heads and “mushroom” tungsten

extenders

An important feature of weld heads is the minimum length a weld component

must be in order to be welded in a particular type or configuration of weld

head. Standard Model 9 weld heads (9-1500 and larger) can be converted to

the “E” configuration in which the electrode is moved to one side of the head.

The housing on the electrode side of the head is removed and replaced by a

gas seal to retain the purge inside the head. Table 2 gives the “A” dimension

which is the minimum length or “stickout” needed to weld components in a

particular head. Welding in “E” heads usually requires tack welding to hold

the components in place for orbital welding. Tungsten extenders, some of

which are called “mushrooms” because of their shape, may be used to locate

the electrode off the centerline and thus reduce the length required to reach

the centerline on that side.

Model 8 weld heads were introduced in 1997 to provide a narrower head with

a shorter stickout requirement. This distance is 0.87 in (22.9 mm) from

either side of the weld head. The Model 8 weld heads can be used for fitting-

to-fitting welds which are not practical in the standard weld heads. Smaller

sized weld heads require less stickout. For example, the required stickout for

the Model 9-500 is 0.250 inches (6.35 mm).

Model 8 Weld Head