Tungsten type – Arc Machines 307 User Manual

Page 148

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096 Chapter 15. Page 1.

Rev. A

C

hapter 15. Tungsten Electrode Specifications for

Orbital Fusion Welding

T

he use of tungsten electrodes is an essential component of the

GTAW (TIG) process. Consistency of tungsten electrode proper-

ties such as type, length, diameter, tip configuration and grind is

important for maintaining the repeatability and quality of orbital

welds and these must be controlled for optimal weld perfor-

mance. The GTAW process in which the electrode conducts

current for the arc but is not consumed by the heat of welding

depends upon the high melting point of tungsten which has the

highest melting point of any metal, 6098

o

F (3370

o

C), compared

to the melting point of iron which is 2800

o

F (1538

o

C).

Tungsten Type

Tungsten properties are improved by the addition of 2% thoria

or ceria which improve the arc strike characteristics and arc sta-

bility. Pure tungsten is seldom used for GTAW because thoriated

and ceriated tungstens have superior properties, especially for

orbital GTAW applications. For tube welding applications, ceri-

ated tungsten is always recommended, as this type main-

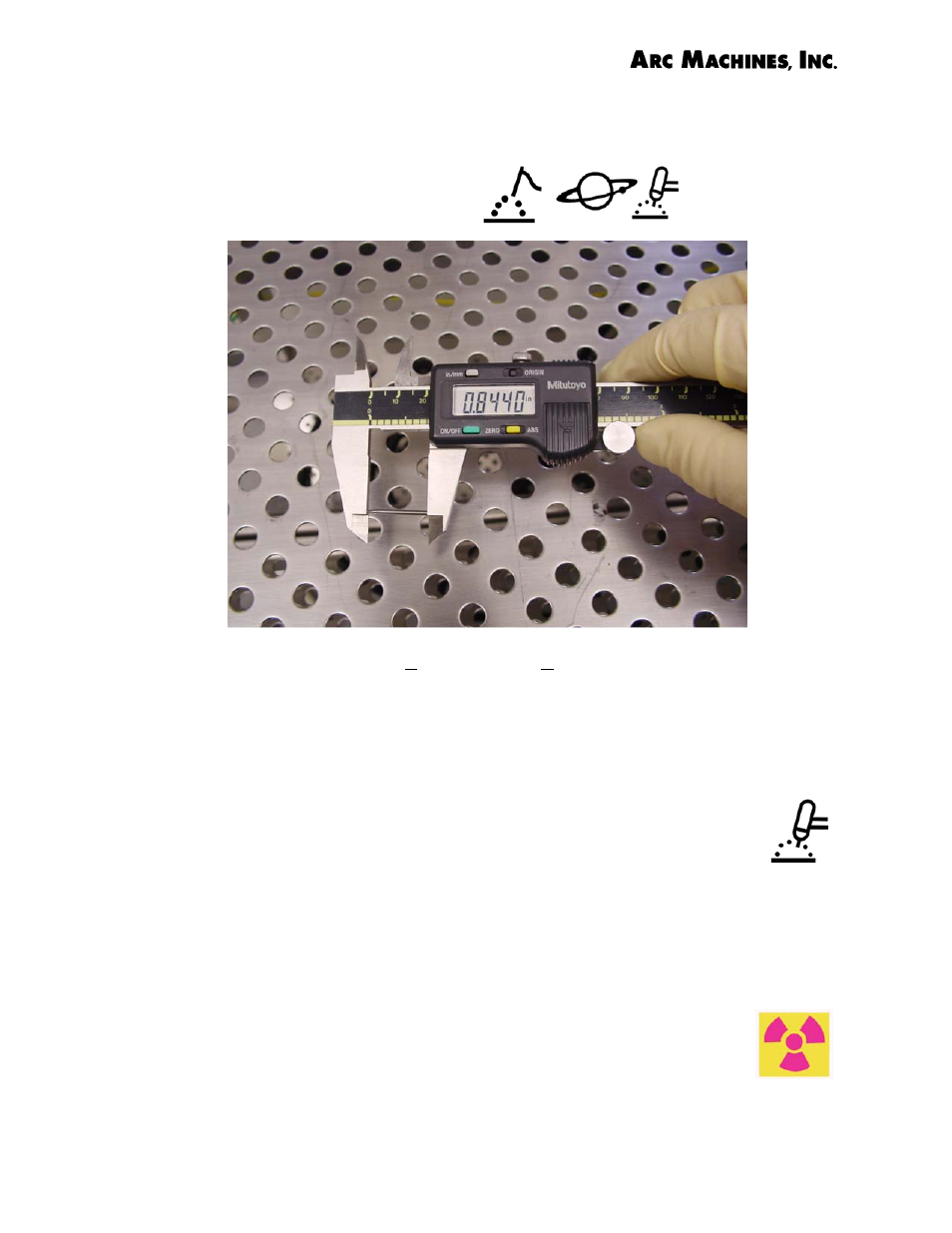

Tungsten electrode length for orbital welding is controlled to the

thousandth of an inch + 0.003 inches ( + .08 mm).

TUNGSTEN

IN GTAW

PROCESS

THORIATED,

CERIATED

TUNGSTEN

2% Th