Arc Machines 307 User Manual

Page 51

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 5. Page 2.

Rev. A

the starting level to full primary Amps in a timed Upslope.

However, There is usually no upslope programmed for autog-

enous welds and the initial welding current will be equal to

primary amps. If Pulse Mode is "On" the current will pulse

between a higher Primary Amps and a lower Background

Amps with pulsation beginning at arc initiation.

A weld schedule consists of a series of timed levels so that

weld parameters (usually amperage) may be changed from

one level to the next, i.e., Level 1 Time, Level 2 Time, etc.

In general, four levels of current is typical but any number of

levels may be programmed. The power supply can also be

programmed to make a weld with two or more passes. At the

end of the last level the current is gradually reduced in a

timed Down-slope. Electrode travel (rotation) is delayed af-

ter arc start for a programmed period of time called Travel

Start delay. Travel stops at the end of downslope and the

weld head rotor returns to home at the end of Postpurge.

The Model 307 Power Supply may be used to automatically

develop weld schedules after the weld head number and

the diameter (O.D.) and wall thickness of the material to be

welded are entered. In generating weld schedules the Model

307 offers a choice of: auto-generated continuous rotation

(CONT), step rotation (STEP), or tack weld (TACK), or

manual generation which can be any of the preceding.

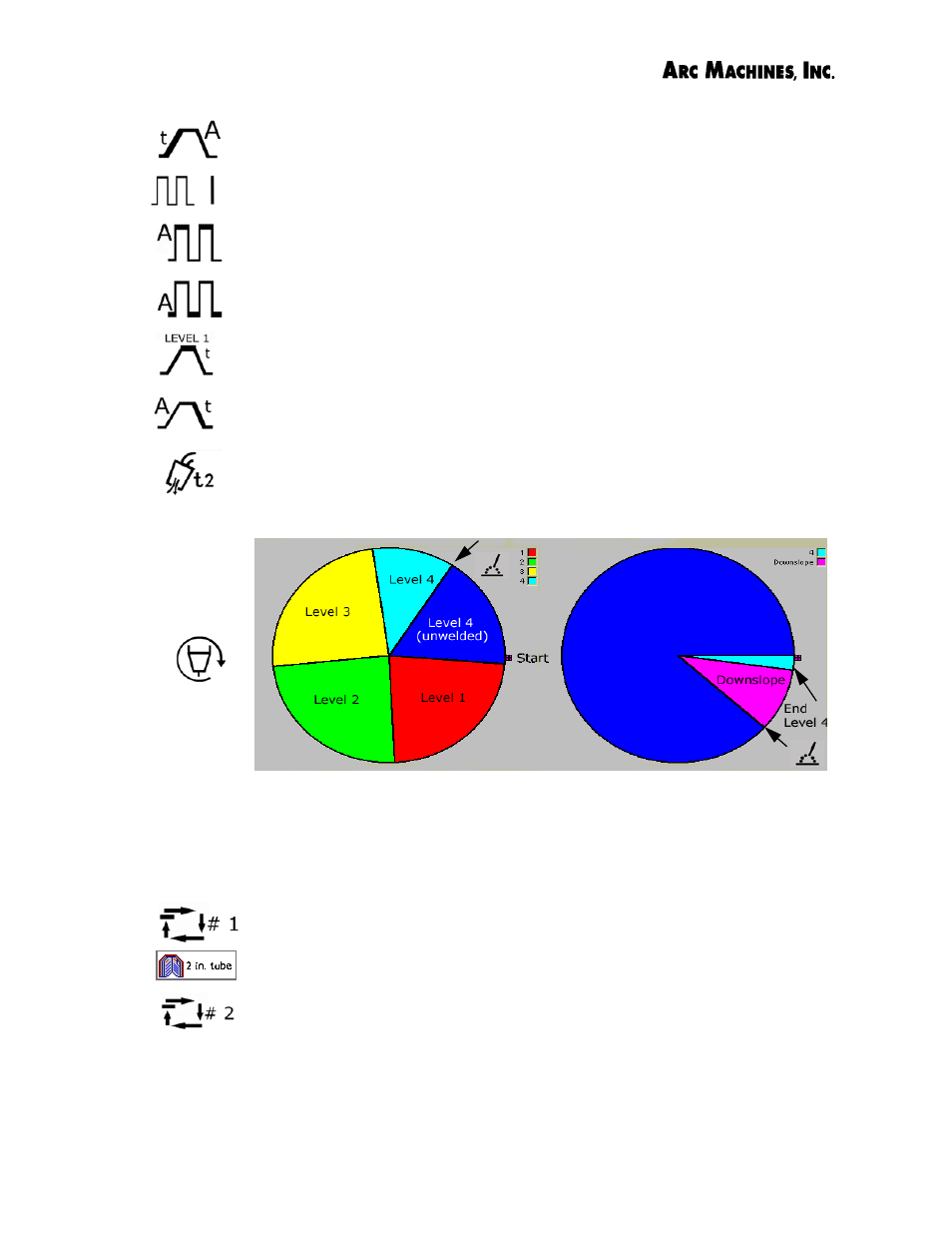

Radial graphs generated by the Model 307 during the welding

sequence show position of electrode on the tube during the weld and

at the end of each level. Left: electrode in the middle of Level 4. Right:

electrode near the end of Downslope. Start position was 3 o’clock.