Cleaning/surface condition – Arc Machines 307 User Manual

Page 146

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096 Chapter 14. Page 2.

Rev. A

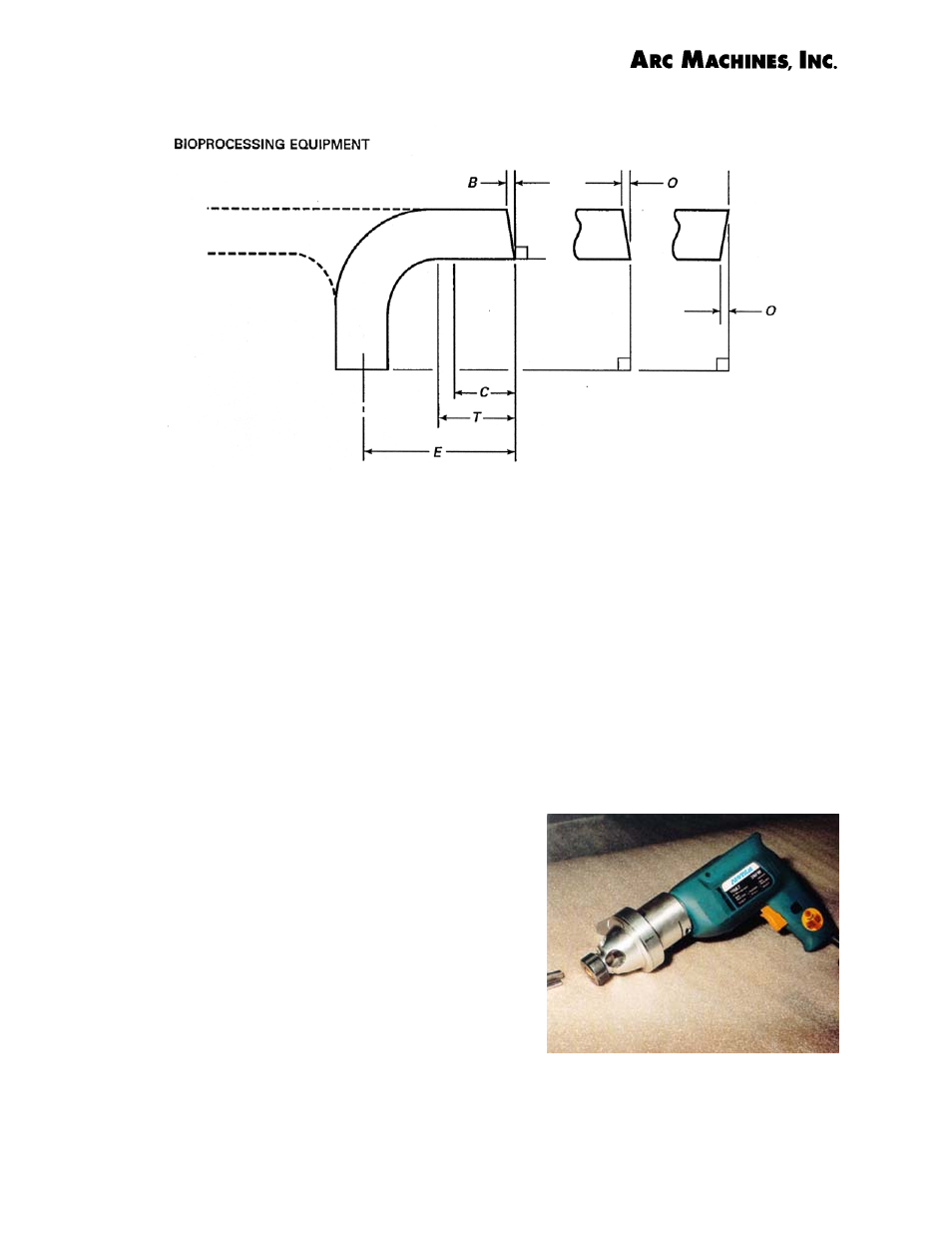

In the drawing from Table DT-5 of the BPE Standard, the B dimension is the

Squareness face to Tangent which increases with tubing size. The Tangent

length (T) is defined as the straight length measured from the welding end. T

varies from 1.50 in on 1/4 inch O.D. tubing to 2.50 inches on 6 inch O.D.

tube. The Control portion, C, is defined as the length from the welding end

over which tolerances for wall thickness and O.D. are maintained. The length

of the control portion is fixed for all sizes at 0.75 in. (19 mm).

Cleaning/Surface Condition

Weld components must be clean in order to achieve good weld results. Clean-

ing procedures vary with industry and application, but the BPE standard in

part DT-12 Surface Condition states that

“Internal and external surfaces of fittings and

process components furnished to this Stan-

dard shall be cleaned to remove oils, grease,

particulates, and grinding componds or elec-

trolytes”. When such fittings are packaged,

the ends are protected with end caps and fit-

tings are sealed in plastic bags or shrink

wrapped. The installer is responsible for

maintaining cleanliness of components dur-

ing the installation and for the condition of

tubing that is cut and prepped on site.

Drawing for Table DT-5 Final Tolerances for Mechanically Polished Fittings and Process Com-

ponents from ASME BPE-2002. Reprinted with permission from the ASME

A facing tool used to produce

machined ends on small diameter

tubing.