Arc Machines 307 User Manual

Page 128

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 11. Page 3.

Rev. A

BEFORE YOU WELD: This is a check list for things that

must be done correctly or set up properly in order to get

consistently good welds. Anyone doing an orbital welding

installation or other orbital welding project should estab-

lish their own written SOPs (Standard Operating Proce-

dures) for all activities related to orbital welding that

must be followed by welding personnel.

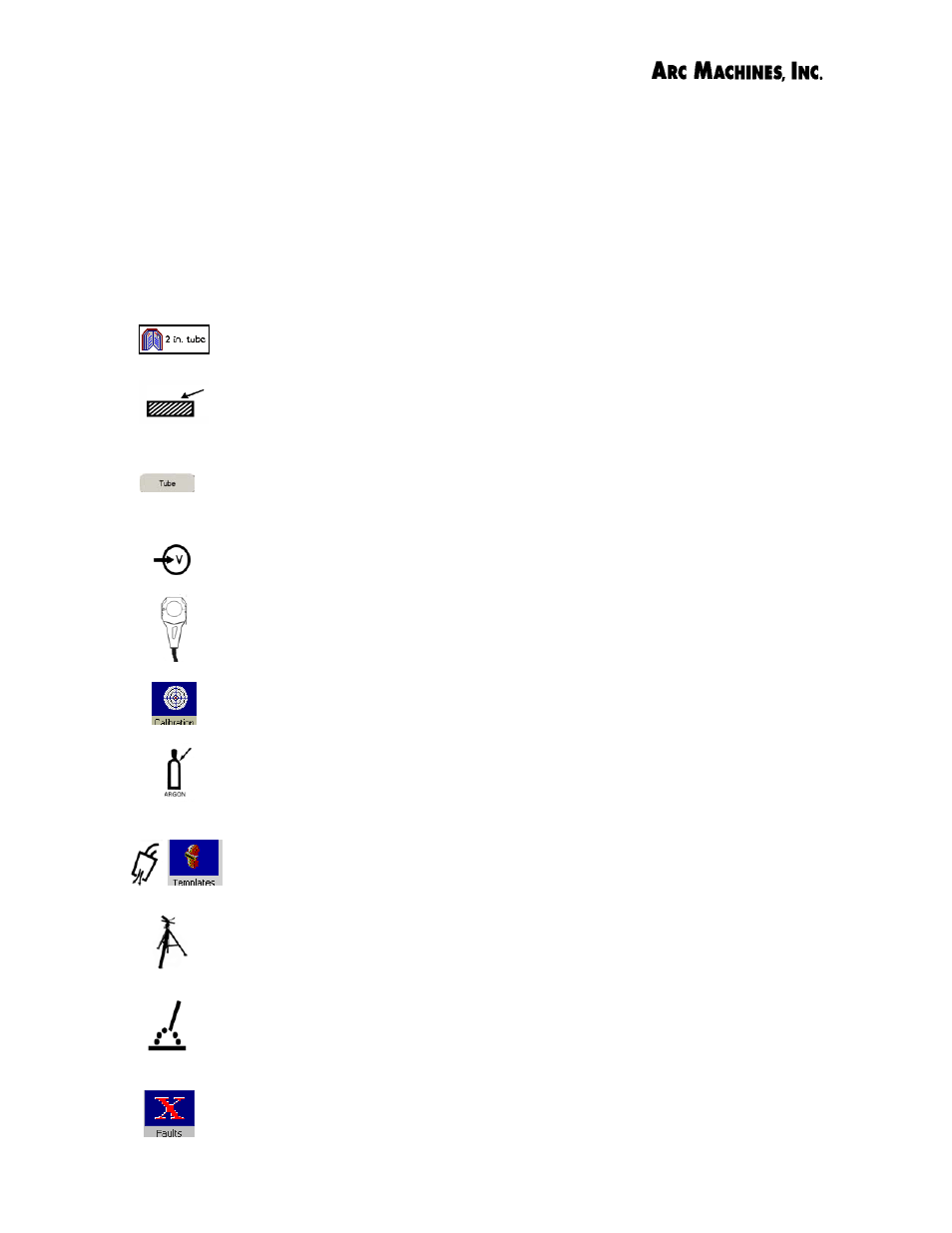

Verify that the Weld Schedule Name is correct.

Is the material type, heat number, OD, and wall thickness

shown on the schedule correct?

Do the weld components have the proper end preparation?

Have they been properly cleaned? (See Chapter 14).

Is the 307 Power Supply set up and properly installed with the

correct line voltage? (Refer to Chapter 4).

Is the weld head set up with correct clamp inserts, electrode

of the correct length? (See Chapter 15).

Is the weld head calibrated to the power supply? (See

Chapter 13 for weld head calibration instructions).

Is the purge gas of the correct type and purity grade

(certification required?) See Chapter 16 for purging

information.

Is the purge gas flow rate correct for the weld head? ID

purge set for correct flow rate and pressure? Touch the

Template icon on the Tool Bar for recommended flow rates.

Are the components correctly aligned and fit up in the weld

head? (See Chapter 17. page 3 for permissible misalignment).

Is the electrode length correct and is it lined up to the weld

joint? (See Chapter 15).

Are the necesssary faults activated? (Don’t forget to turn off

the Stubout Fault when using a manual torch). On the 307

Opening Screen choose System Set-up and then Faults.