Arc gap, Tungsten diameters, Table 1: tungsten length and geometry – Arc Machines 307 User Manual

Page 150

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096 Chapter 15. Page 3.

Rev. A

Arc Gap

The tungsten length is used to set the arc gap for

fusion tube welding.The ARC GAP at a particular cur-

rent value determines the voltage and thus the power

applied to the weld.

The arc gap will remain constant as long as the tube is

perfectly round. Pipe is never perfectly round and the

arc gap must be controlled to maintain a constant arc

gap around the entire weld circumference. The Model

95 wire feed weld head has a mechanical arc gap

controller.

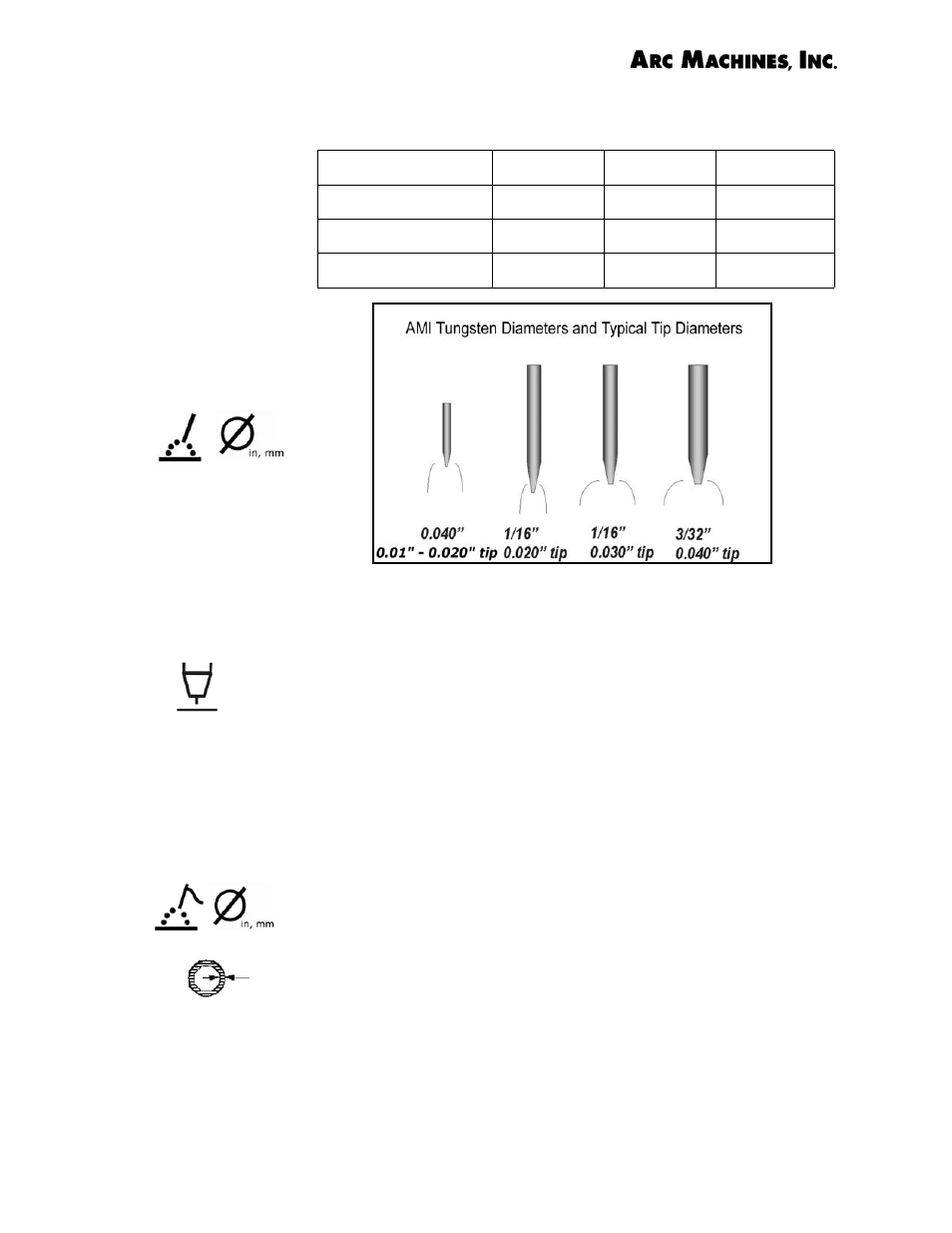

Tungsten Diameters

Tungsten diameters for fusion welding are based on

wall thicknesses. Model 9 weld heads, except for the

Model 9-250 and Model 9-500 which only accept 0.040”

tungsten, accept two different tungsten diameters. For

the Model 9AF-750, the Model 9-900, and the Model

9/AF-900 weld heads, 1/16” diameters are used for

most applications. For the larger heads, the use of

either 1/16” or 3/32” diameters is based on wall thick-

ness. The use of 1/16” tungsten for wall thicknesses up

to 0.093”, and 3/32” tungsten for heavier wall thick-

nesses is recommended.

Table 1: TUNGSTEN LENGTH AND GEOMETRY

Wall Thickness

Arc Gap

Tip Dia.

Tung. Dia.

.020”-.035”

.030”

.020”

.040”

.049” -.083”

.050”

.030”

.062”

.091” -.154”

.070”

.040”

.093”