Model 307-cw installation – Arc Machines 307 User Manual

Page 41

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 4. Page 7.

Rev. A

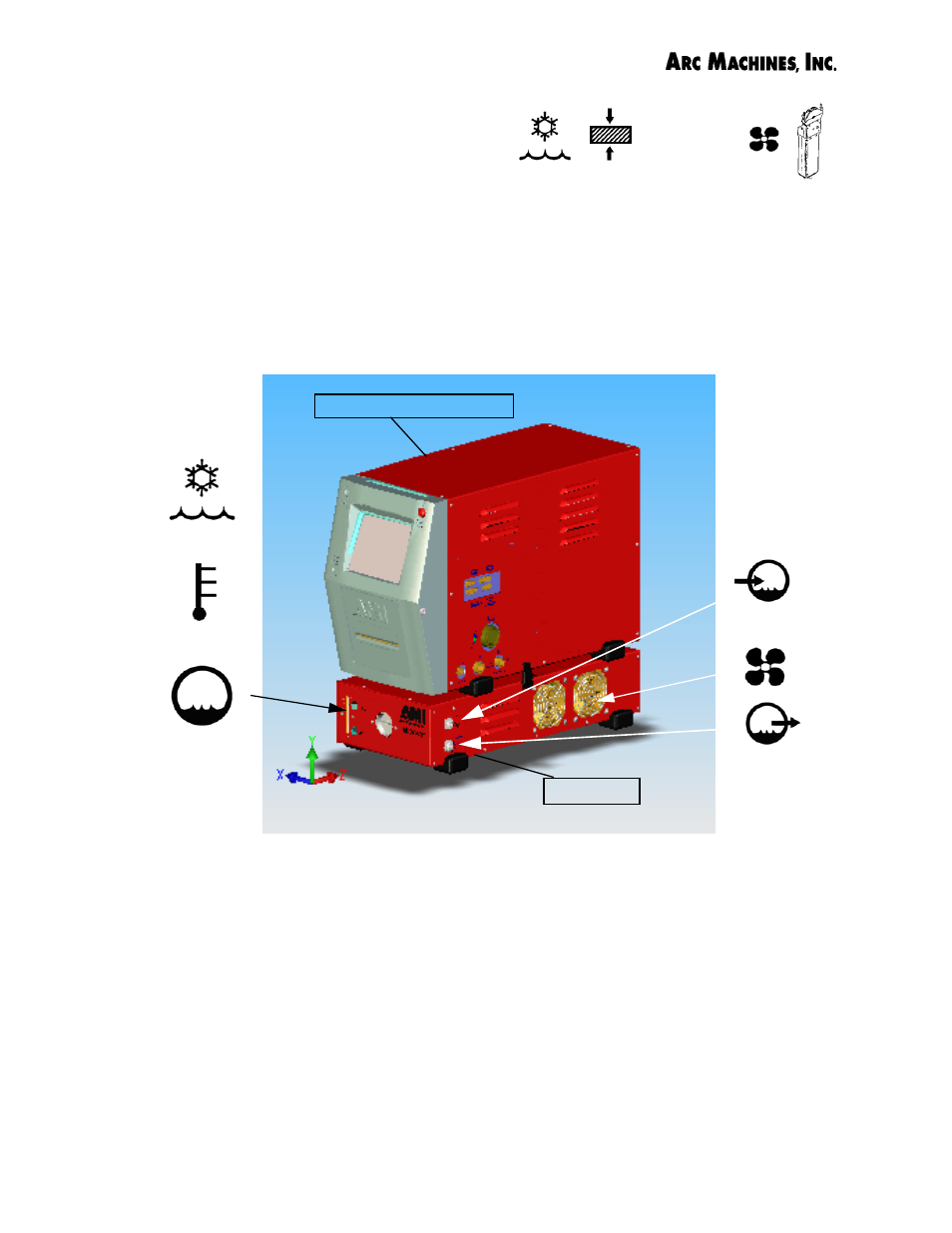

MODEL 307-CW INSTALLATION

The Model 307-CW mounts beneath the 307 power supply and cir-

culates water and coolant through the weld heads and cables to prevent

overheating. The CW is recommended for welding heavy-walled materi-

als or for bench welding where high productivity is required. Most AMI

weld heads are water-cooled but the Model 9-500 and 9-250 weld heads

are not. Heads without water cooling may be cooled between welds by

placing in front of a fan.

Note: The 9-500C weld head is a water-cooled version of the 9-500.

Input power The Input Power cable is attached to the back of the Model

307-CW and connected to the back of the Model 307 power supply.

The 307 Adapter cable has two water fittings that connect into the op-

tional 307-CW. Water circulates from the CW through those hoses to the

weld head and back to the CW.

The maximum flowrate for the 307-CW is 2 liters per minute (.5 gal-

lons) at 35 PSI. The maximum delivery pressure is 45 PSI with a bypass

relief valve. Total 307-CW water capacity is 0.75 Gallons U.S. (2.8 liters).

A glycol coolant-water mixture is recommended. The M307-CW unit op-

erates on 12 volts DC at 2.6 Amps (4 AMP indicated rating is for

Model 307 Power Supply and Optional 307-CW

coolant IN

coolant OUT

Model 307 Power Supply

307-CW