Concavity and convexity, Misalignment, Tack welds – Arc Machines 307 User Manual

Page 164

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 17. Page 3.

Rev. A

Any weld bead in which the narrowest part of the OD weld bead is less than

50% of the widest part, is not acceptable. Excessive weld bead meander

where a weld bead has less than 25% of its width over the centerline of the

OD weld bead is not acceptable.

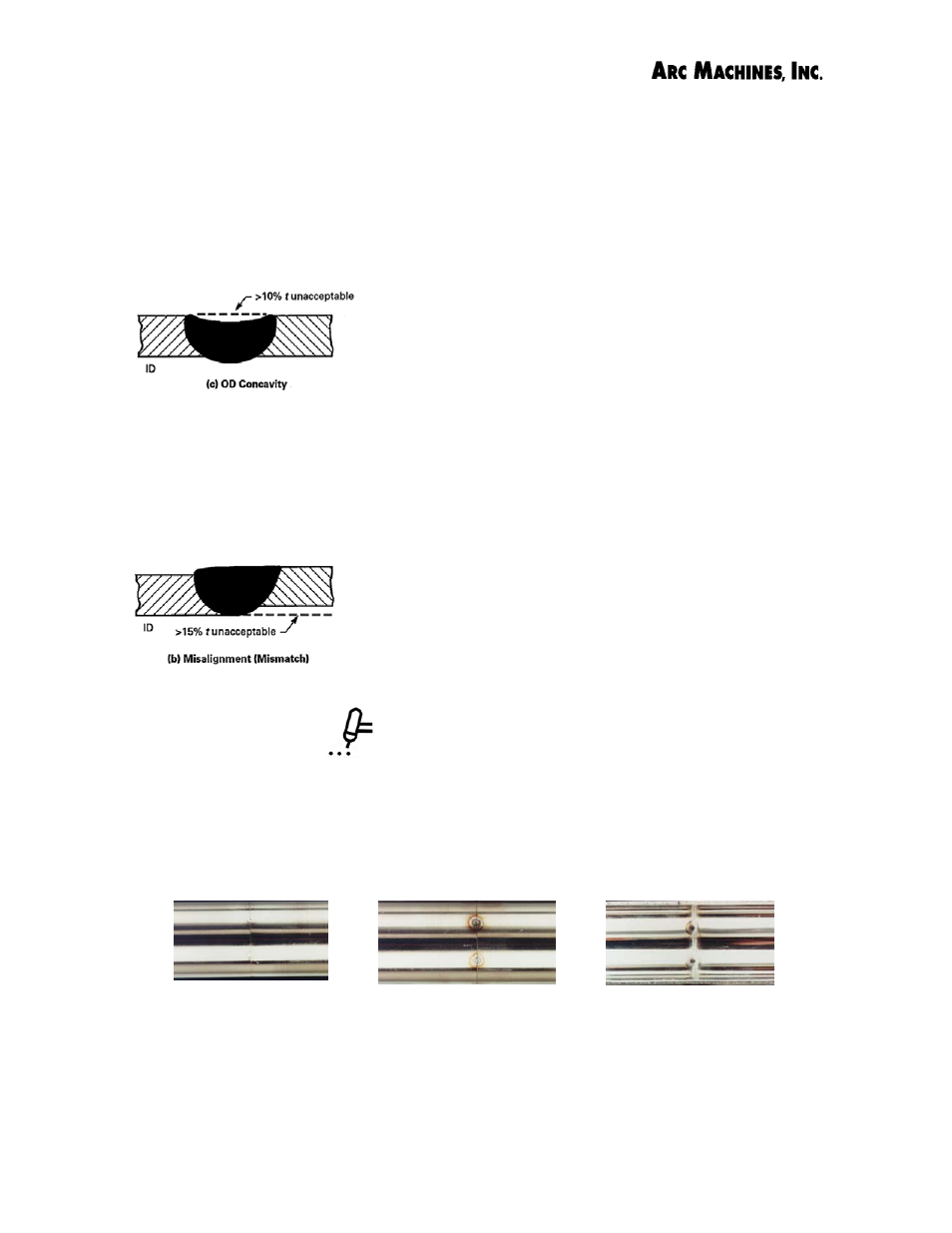

Concavity and convexity.

An autogenous orbital weld should be flush on the

ID and OD surfaces. The ASME BPE-2002 stand-

ard provides a set of weld profiles showing ac-

ceptable limits for OD and ID concavity and

convexity and specifies that the weld joint thick-

ness must not be less than the minimum speci-

fied wall thickness for the material. The D18.1

standard also sets limits on concavity and convexity since these discontinu-

ities could affect the drainability and cleanability of sanitary piping systems.

Misalignment

Limits on misalignment are also specified by SEMI,

ASME BPE-2002, and AWS D18.1 since this could

affect the drainability of fluid systems or affect flow

in gas distribution systems.

Tack welds

ASME BPE-2002 requires that tack welds be fully consumed. Unconsumed

tack welds have been identified as a major cause of weld rejection. The pho-

tos below illustrate the importance of proper purging of tack welds.

The weld sample on the left was purged during tacking. Purged tacks are easily consumed

by the orbital weld. The center sample shows unpurged tacks. The orbital weld on the right

has unconsumed tacks as the arc deflected around the oxidized (unpurged) tacks.