Arc Machines 307 User Manual

Page 7

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 1. Page 1.

Rev. A

C

hapter 1. Introduction to Orbital Welding with

the Model 307 Power Supply

rc Machines’

new Windows™-

based Model 307 Power

Supply is designed for

autogenous orbital GTA

welding. In addition to

the standard tube-weld-

ing functions it also has

wire feed capabilities.

The Model 307 was

developed for economy

and ease of use and will

automatically generate a

weld schedule or pro-

gram when the Arc

Machines weld head and

weld component dimen-

sions are entered. To

meet the Industry’s demands for quality assurance (QA) and weld data

collection, the Model 307 has extensive capabilities to store and transmit

detailed weld documentation and historical data.

Welding personnel can program the Model 307 in time per level or simply

enter the desired weld head position in rotational degrees for the end of

each level, and time required to complete the level will be entered auto-

matically. Weld parameters are clearly visible on the 307’s touch screen

and can easily be modified by the operator if changes should be necessary.

Input Power. The Model 307 Power Supply operates on 110 to 240 VAC,

50/60 Hz, single phase only, without reconnection.

Weld Current. The Model 307 has a programmable range of 5 to 200

amperes of primary welding current, while average current is software-lim-

ited to 150 amps or less. The Model 307 will warn users if programmed

current values exceed recommendations for particular weld heads.

Weld Heads. The Model 307 operates all standard AMI fusion weld heads

including the Model 8 and Model 9 series, Model 4, Model 85, and Model 96.

It can also operate the Model 95 series of wire-feed weld heads. The motor

controls can accept DC tachometer velocity feedback, or quadrature-encod-

er position and velocity information.

A

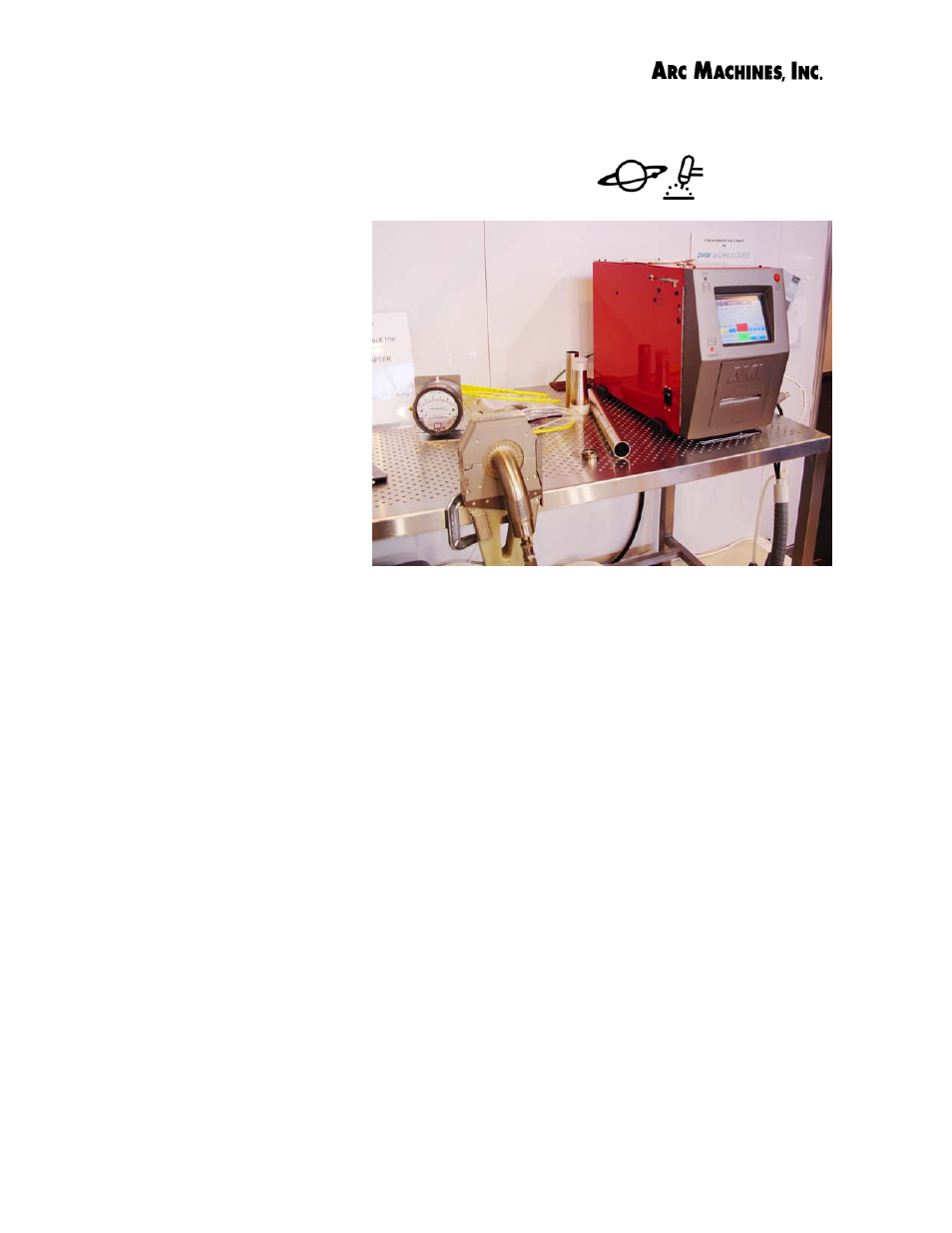

Arc Machines’ Model 307 Power Supply and Model 8-2000 weld

head on a cleanroom bench at the WELDEX show in the UK.