Rockwell Automation 1771-QI,D17716.5.126 PLASTIC MOLD.MODULE User Manual

Page 61

2–29

Command Word/Bit Descriptions

Publication 1771-6.5.126 – March 1998

MCC

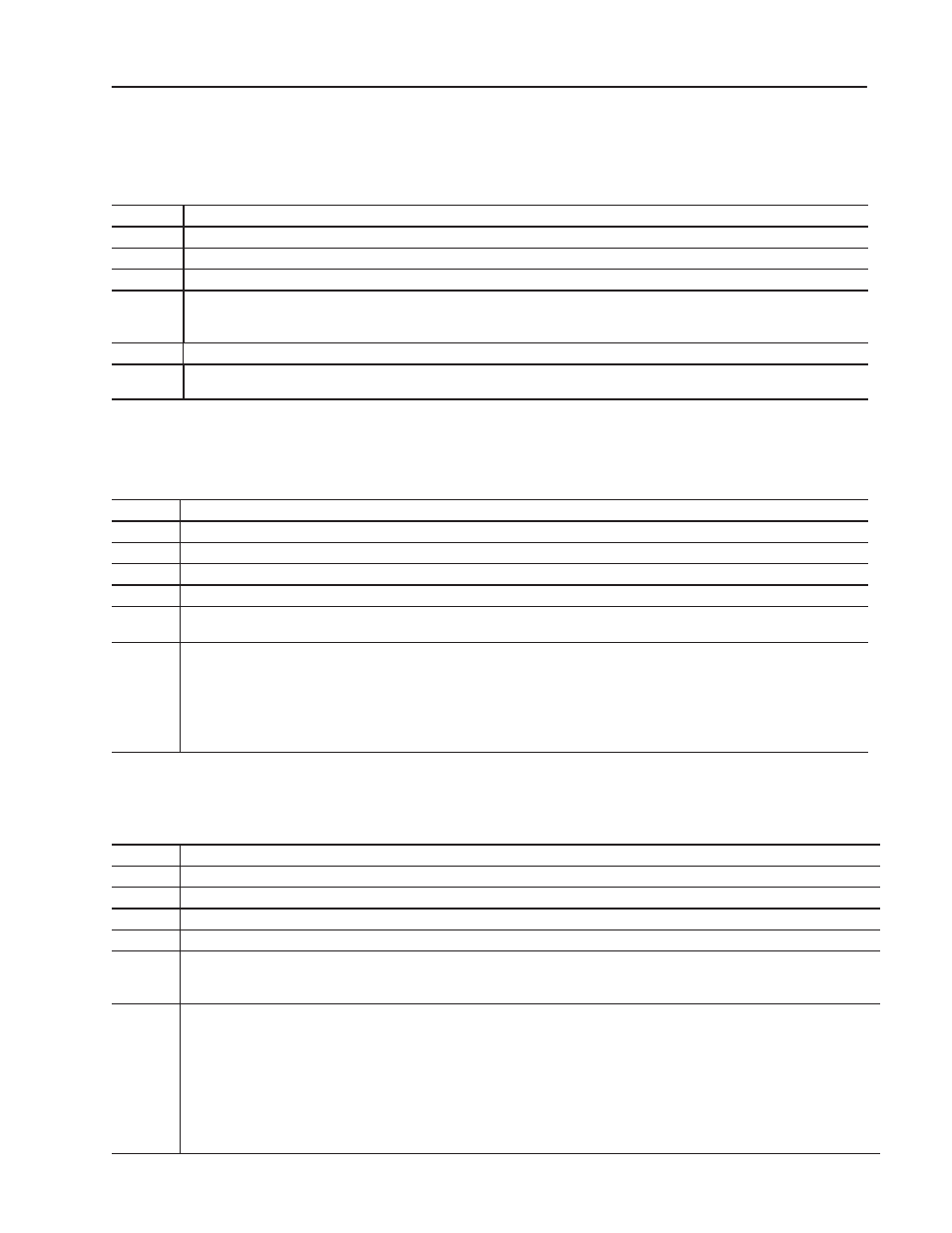

Ram (Screw) Position Transducer Configuration (other injection head)

The module accesses data in MCC09-16 if bit patterns in MCC02, 03

indicate that the module is connected to a ram (screw) position sensor.

Word

Description

MCC23

Minimum Ram (Screw) Position [11]

MCC24

Maximum Ram (Screw) Position [11]

MCC25

Analog Signal at Minimum Ram (Screw) Position [24]

MCC26

Analog Signal at Maximum Ram (Screw) Position [24] The module continuously compares real-time ram (screw) position against

this entry. The module sets alarm status bit SYS07-B00 and forces all of its outputs to zero when executing a ram (screw) forward

profile (Injection, Pack, Hold) and ram (screw) position is less than or equals this entry. A zero entry inhibits SYS07-B00.

MCC27-29

RFU

MCC30

Ram (Screw) Position Transducer Digital Filter [23] A non-zero entry forces the module to filter the input before using the result for

ram (screw) position calculations. Use this parameter when required to soften the input signal from a linear potentiometer.

Screw RPM Transducer Configuration

The module accesses data in MCC51-56 if bit patterns in MCC02 and

MCC03 indicate that the module is connected to a screw RPM sensor.

Word

Description

MCC51

Minimum Screw RPM [25]

MCC52

Maximum Screw RPM [25]

MCC53

Analog Signal at Minimum Screw RPM [24]

MCC54

Analog Signal at Maximum Screw RPM [24]

MCC55

High Screw RPM Alarm Setpoint [25] The module continuously compares real-time screw RPM against this entry. The module sets

alarm status bit SYS05-B03 when screw RPM equals or exceeds this entry. A zero entry inhibits SYS05-B03.

MCC56

High Screw RPM Alarm Time Delay [23] Total time the module must monitor a continuous screw RPM in excess of the non-zero

entry in all screw RPM alarm setpoints before setting the associated alarm status bit. Setpoint/bitpairs affected are:

Setpoint

Alarm Status Bit

MCC55

SYS05-B03

JGC05

SYS05-B08

Use a non-zero entry in this word to filter out screw RPM spikes of short enough duration to avoid nuisance alarms.

Cavity Pressure Transducer Configuration

The module accesses data in MCC57-62 if bit patterns in MCC02, 03

indicate that the module is connected to a cavity pressure sensor.

Word

Description

MCC57

Minimum Cavity Pressure [04]

MCC58

Maximum Cavity Pressure [04]

MCC59

Analog Signal at Minimum Cavity Pressure [24]

MCC60

Analog Signal at Maximum Cavity Pressure [24]

MCC61

High Cavity Pressure Alarm Setpoint [04] The module continuously compares real-time cavity (or system) pressure against this entry.

The module sets alarm status bit SYS05-B04 when cavity (or system) pressure equals or exceeds this entry. A zero entry inhibits

SYS05-B04.

MCC62

High Cavity Pressure Alarm Time Delay [23] Total time the module must monitor a continuous cavity (or system) pressure in excess of

the non-zero entry in all cavity (or system) pressure alarm setpoints before setting the associated alarm status bit.

If bit patterns in MCC02 and MCC03 indicate that the module is connected to a cavity pressure sensor, setpoint/bit pairs affected are:

Setpoint

Alarm Status Bit

MCC61

SYS05-B04

INC58

SYS06-B01

PKC58

SYS06-B03

HDC58

SYS06-B05

Use a non-zero entry in this word to filter out cavity pressure spikes of short enough duration to avoid nuisance alarms.