Rockwell Automation 1771-QI,D17716.5.126 PLASTIC MOLD.MODULE User Manual

Page 32

1–22

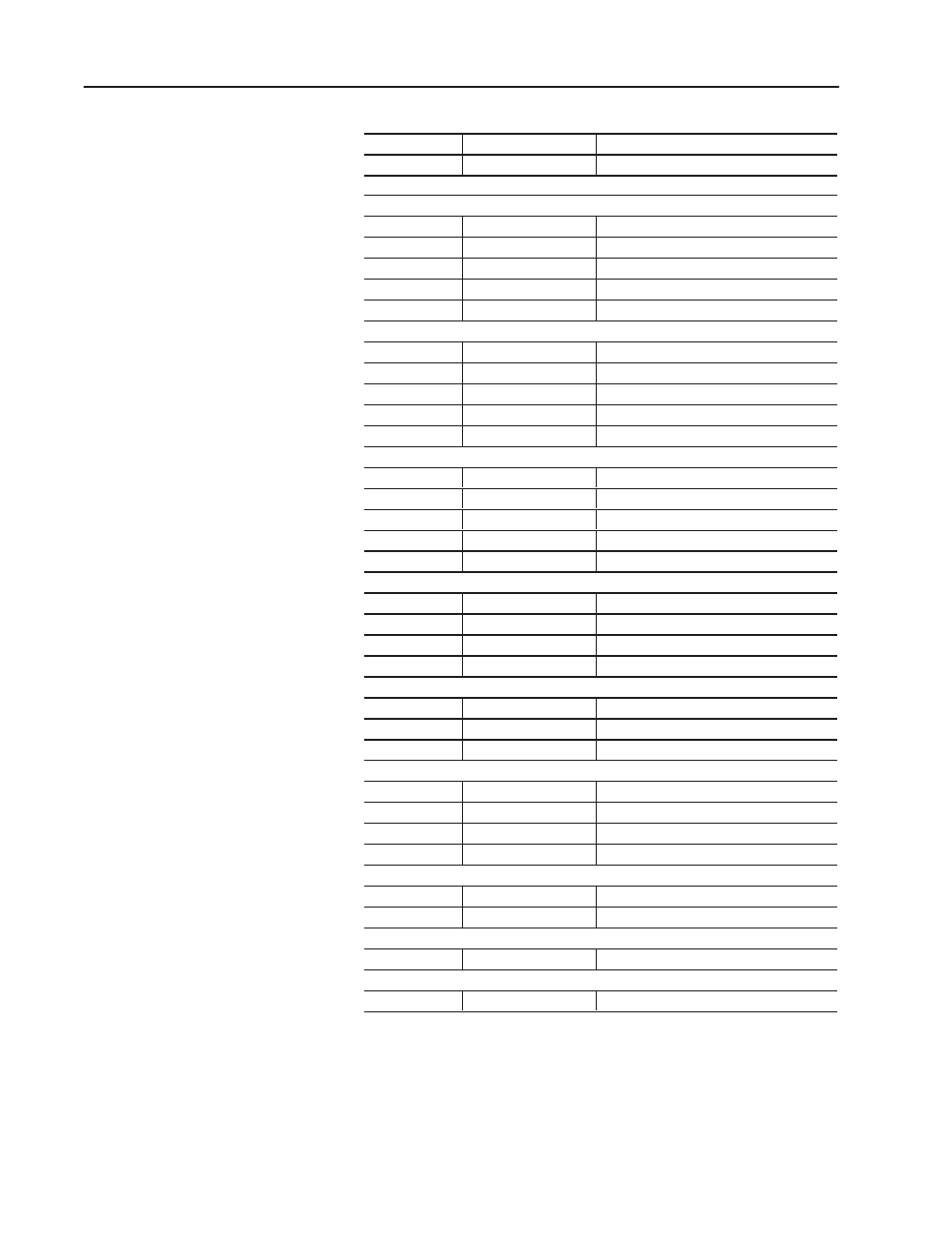

Abbreviated Command and Status Blocks

Publication 1771-6.5.126 – March 1998

Bit-Mapped Status Words (continued)

SYS23*_0**

B34:22*

B21:18**

Status of trace data collection in progress

SYS24*_0**

B34:23*

B21:19**

Status of process trace data collected

*Pro-set 600 **Pro-Set 700

For example, MCC05_0 is correct for Pro-Set 700.

Input Level in Engineering Units

SYS25

N40:177

Input #1

SYS26

N40:178

Input #2

SYS27

N40:179

Input #3

SYS28

N40:180

Input #4

SYS29-32

N40:181-184

RFU

Input Level, Raw Signal Level at A/D Converter

SYS33

N40:185

Input #1

SYS34

N40:186

Input #2

SYS35

N40:187

Input #3

SYS36

N40:188

Input #4

SYS37-40

N40:189-192

RFU

Output Level in Percent

SYS41

N40:193

Output #1

SYS42

N40:194

Output #2

SYS43

N40:195

Output #3

SYS44

N40:196

Output #4

SYS45-48

N40:197-200

RFU

Maximum Pressures of Each Cycle

SYS49

N40:201

Maximum ram (screw) pressure, last cycle

SYS50, 51

N40:202, 203

RFU

SYS52

N40:204

Maximum cavity pressure, last cycle

SYS53

N40:205

RFU

Process Trace

SYS54

N40:206

Process trace data collection in progress

SYS55

N40:207

Process trace data collection done

SYS56

N40:208

RFU

Accumulated Process Times

SYS57

N40:209

Tonnage

SYS58

N40:210

Cure

SYS59

N40:211

Mold open dwell

SYS60

N40:212

Cycle

Programming Error Codes

SYS61

N40:213

ID of data block with error

SYS62

N40:214

Programming error code

Firmware ID

SYS63

N40:215

Module Series/Revision

Confirmation of New Status

SYS64

N40:216

Counter accumulated value, each new SYS