Engineering units, Data blocks require i/o configuration – Rockwell Automation 1771-QI,D17716.5.126 PLASTIC MOLD.MODULE User Manual

Page 34

2–2

Command Word/Bit Descriptions

Publication 1771-6.5.126 – March 1998

Notes: For [ ] engineering units, see page 2.

Bit-mapped Words

The first several words in any data block are bit-mapped. For

bit-mapped command words, you must set/reset or latch/ unlatch

command bits to set QI module operating configurations.

Stored-value Words

These words establish operating conditions for the QI module, such as:

•

output values for certain conditions

•

minimum and maximum pressures, positions, and velocities

•

alarm setpoints

Reserved Words (RFU)

These words are Reserved for Future Use. Do not use them.

In the listings of command blocks, each stored-value word is followed

by a bracketed [ ] 2-digit number code denoting the engineering units

and range associated with the value as shown in the following table:

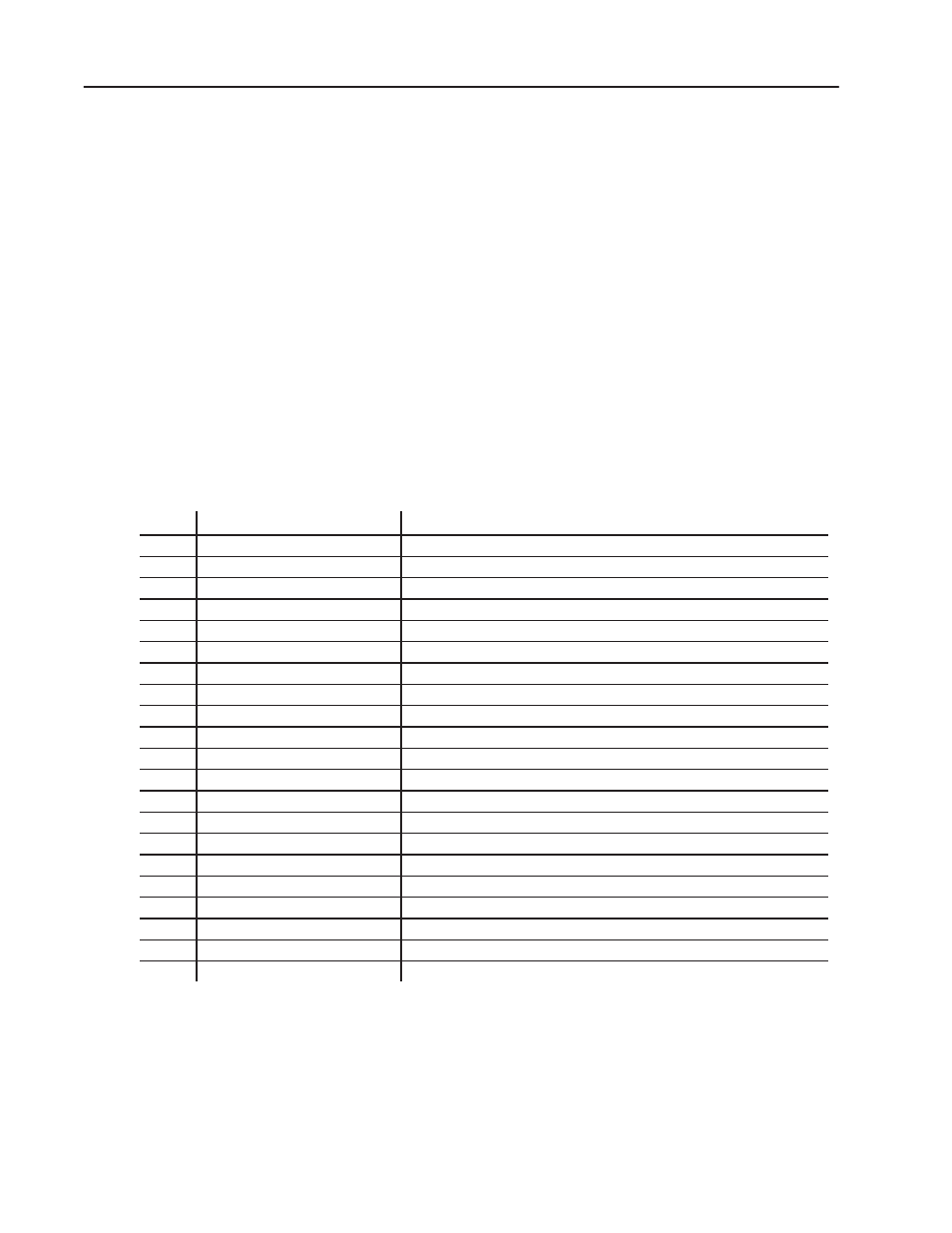

#Code

Type of Block

Units and Range

01

Ram (Screw)

Pressure (0000.0 to 9999.0 PSI or 000.0 to 999.9 Bar)

04

Cavity

Pressure (00000.0 to 20000.0 PSI or 0000.0 to 2000.0 Bar)

05

Ram (Screw)

Percent of maximum velocity (00.00 to 99.99%)

06

Ram (Screw)

Velocity along axis (00.00 to 99.99 in. per sec. or 000.0 to 999.9 mm per sec.)

11

Ram (Screw) Measured from zero

Incremental distance (00.00 to 99.99 in. or 000.0 to 999.9 mm.)

12

Ram (Screw) Measured from MCC13

Incremental distance (00.00 to 99.99 in. or 000.0 to 999.9 mm.)

17

Measured as noted in text

Incremental distance (00.00 to 99.99 in. or 000.0 to 999.9 mm.)

18

Measured as noted in text

Incremental distance (00.00 to 00.99 in. or 000.0 to 009.9 mm.)

19

Percent signal output (00.00 to 99.99%)

20

Percent signal output per second (0000. To 9999.)

21

Time measured in seconds (00.00 to 99.99)

22

Time measured in seconds (000.0 to 999.9)

23

Time measured in seconds (00.00 to 00.99)

24

Input signal range (00.00 to 10.00 or 01.00 to 05.00 or 04.00 to 20.00)

25

Screw rotational speed (000.0 to 999.9 RPM)

26

Time (algorithm) (00.00 to 9.99 minutes)

27

Inverse time (algorithm) (00.00 to 99.99 inverse minutes)

28

Inverse time (algorithm) (00.00 to 99.99 inverse seconds)

29

Unit-less

30

Binary Bit Map: bit value of 0 or 1; range of 00-15

31

Percent (00.00 to 99.99%)

The QI module decodes its own I/O configuration based on parameters

that you provide in the Module Configuration Command Block (MCC).

I/O configuration determines which of the command and status blocks

the module supports. For the module to support command and status

blocks, you must establish the following position input:

•

Connect a ram (screw) position sensor to input 1.

Engineering Units

Data Blocks Require I/O

Configuration