A then b, Standard programming, Co-injection programming – Rockwell Automation 1771-QI,D17716.5.126 PLASTIC MOLD.MODULE User Manual

Page 134

5–2

Sequencing Co-injection

Publication 1771-6.5.126 – March 1998

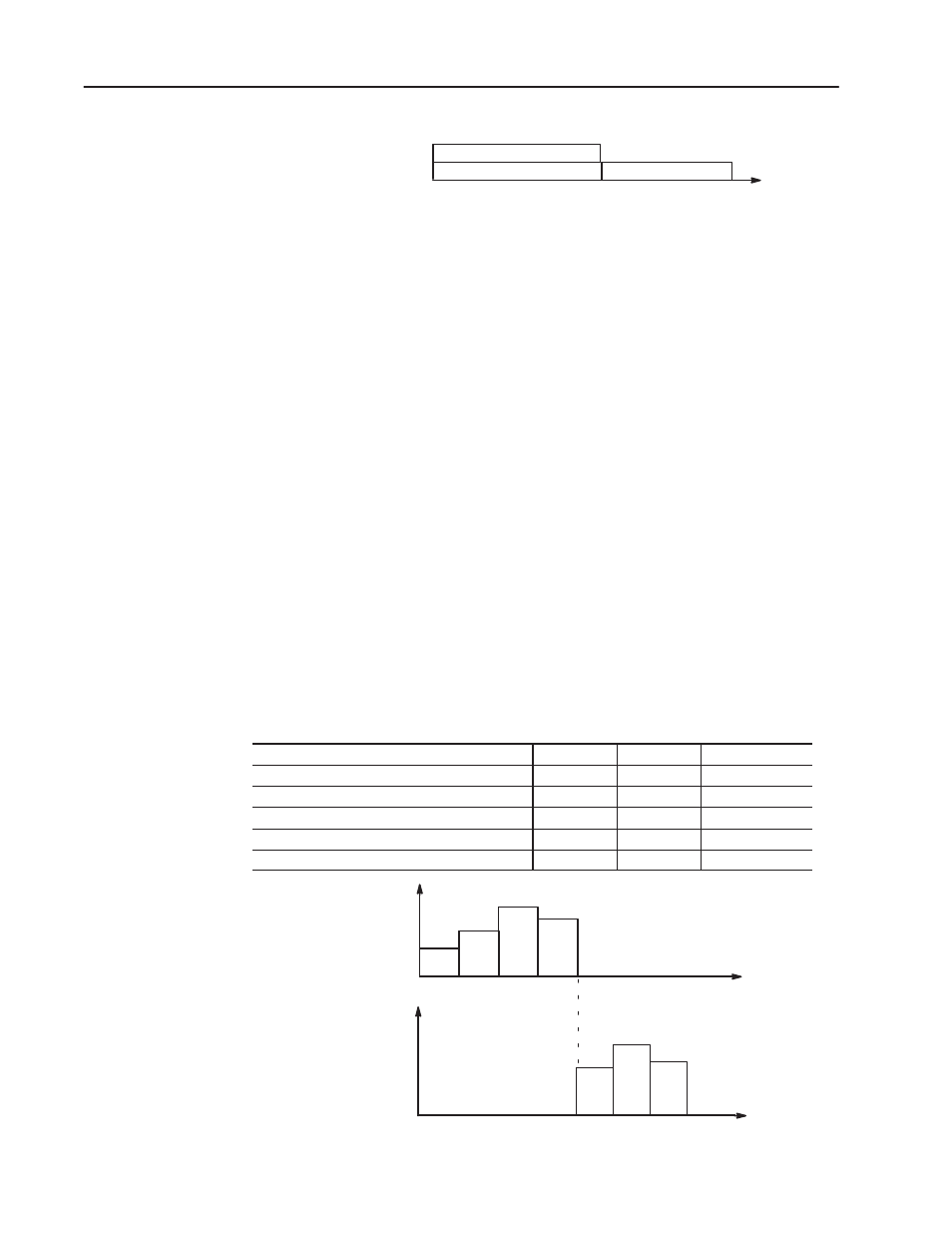

You can use either standard or co-injection programming for this sequence.

ЙЙЙЙЙЙЙЙ

ЗЗЗЗЗЗ

ЗЗЗЗЗЗ

A

B

Time

Standard Programming

Set up QI(A) to wait at the end of its injection profile, and QI(B) to

bridge into pack/hold. You command QI(A) to inject to completion

and wait. Once your ladder code sees injection complete bit

(SYS02:B04) transition from F to T, your code commands QI(B) to

start injection. When QI(B) completes injection, it will automatically

bridge to pack/hold and complete the cycle.

This technique requires one program scan (20 to 50 msec) before

QI(B) is commanded to start injection. If you require a faster

response, use co-injection programming.

Co-injection Programming

Use co-injection parameter IPCB08 to define the screw position of A

at the end of its profile at which to start QI(B)’s injection. You

command QI(A) and (B) to start at the same time. QI(A) completes

first and waits at the end of its profile. QI(B) starts injection when A

reaches screw position (aaa) set in IPCB08. Once QI(B) completes

injection, it goes into pack/hold and completes the cycle.

This technique starts QI(B)’s profile within 2 msec of seeing screw

position (IPCB08) at the end of QI(A)’s profile.

Description:

QI(A) setup:

QI(B) setup:

Co–inj. word/bit:

enable injection cycle suspension on start

No

Yes

DYCB03-BO4 = 1

disable automatic sequence into pack/hold

Yes

No

IPC02-B08 = 1

enable injection cycle suspension on screw position

No

No

IPC02-B10 = 0

screw position (of other) to exit suspended injection

No

at aaa

IPCB08 = aaa

screw position to suspend own injection

No

No

IPC56 = zero

QI(A)’s Injection Profile

aaa

1

2

3

4

2

1

3

0

0

QI(B)’s Injection Profile

Pressure

Pressure

Time

Time

suspended start

A then B