Data blocks for system control, Data blocks for controlling ram (screw) position – Rockwell Automation 1771-QI,D17716.5.126 PLASTIC MOLD.MODULE User Manual

Page 35

2–3

Command Word/Bit Descriptions

Publication 1771-6.5.126 – March 1998

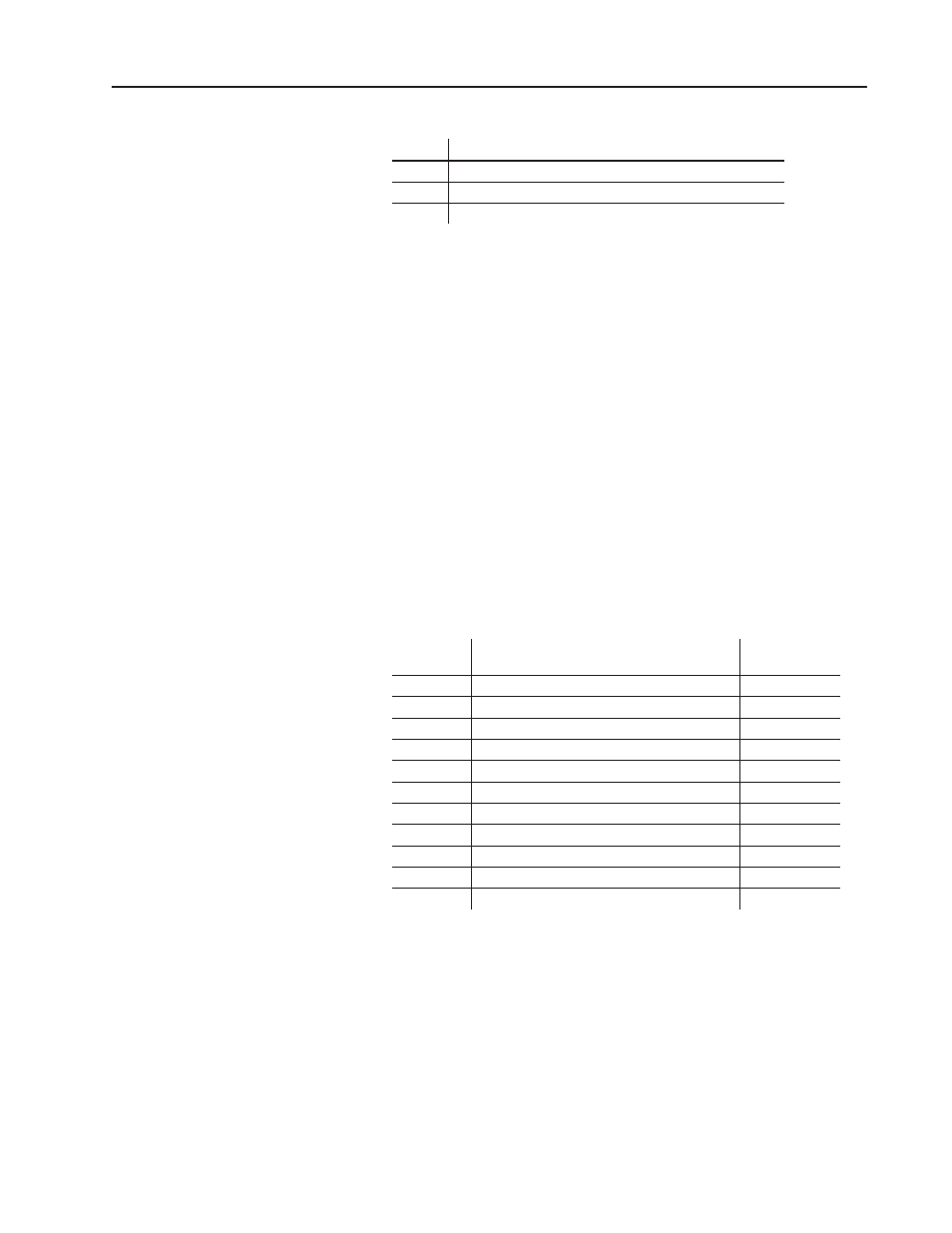

Command Blocks for system level control are:

Block

Description

MCC

Module Configuration Command Block

JGC

Jog Configuration Command Block

DYC

Dynamic Command Block

You must establish the QI module’s I/O configuration before it can

decide which command blocks to support. Although the module always

accepts the Module Configuration Command Block (MCC), the module

considers all other command blocks unrecognizable until it has received,

processed, and successfully error checked an MCC download from the

host processor. After you configure the QI module with a valid MCC,

the module always accepts and processes (considers them recognizable)

either of the two basic command blocks JGC and DYC when received.

The module reports system status in the system status block (SYS). The

module can always return the System Status Block to the host processor.

It returns this block after each block transfer read (BTR) request from the

PLC processor unless the previous block transfer write (BTW) to the

module was a valid dynamic command block (DYC) containing a request

for some other status block.

The host processor can write any of these command blocks to the QI

module to control ram (screw) position:

Command

Block

Description

Corresponding

Status Block

INC

Injection Configuration Block

–

IPC

Injection Profile Block

IPS

PKC

Pack Configuration Block

–

HDC

Hold Configuration Block

–

HPC

Pack/Hold Profile Block

HPS

PRC

Pre-decompression Configuration Block

–

PLC

Plastication Configuration Block

–

PPC

Plastication Profile Block

PPS

PSC

Post-decompression Configuration Block

–

PTC

Process Trace Configuration Block

PTS

RLC

Inject ERC Values Block

RLS

After you configure the QI module with a valid MCC, the module

determines if it has access to ram (screw) position data from the ram

(screw) position sensor. The module considers these command

blocks recognizable and can return these status blocks when it has an

analog input reserved for a ram (screw) position sensor, and the

sensor is physically connected to input 1.

Data Blocks for System

Control

Data Blocks for

Controlling Ram (Screw)

Position