Flow chart for co- injection programming, Flow chart for co-injection programming – Rockwell Automation 1771-QI,D17716.5.126 PLASTIC MOLD.MODULE User Manual

Page 138

5–6

Sequencing Co-injection

Publication 1771-6.5.126 – March 1998

Your ladder logic must monitor conditions and set command bits for QI

modules to step through the various algorithms of co-injection. For the

example of ABA, we present a list of parameters, a diagram, and a flow

chart that indicates the logic that QI modules expect to see. (Remember

that screw position values decrease going toward the mold.)

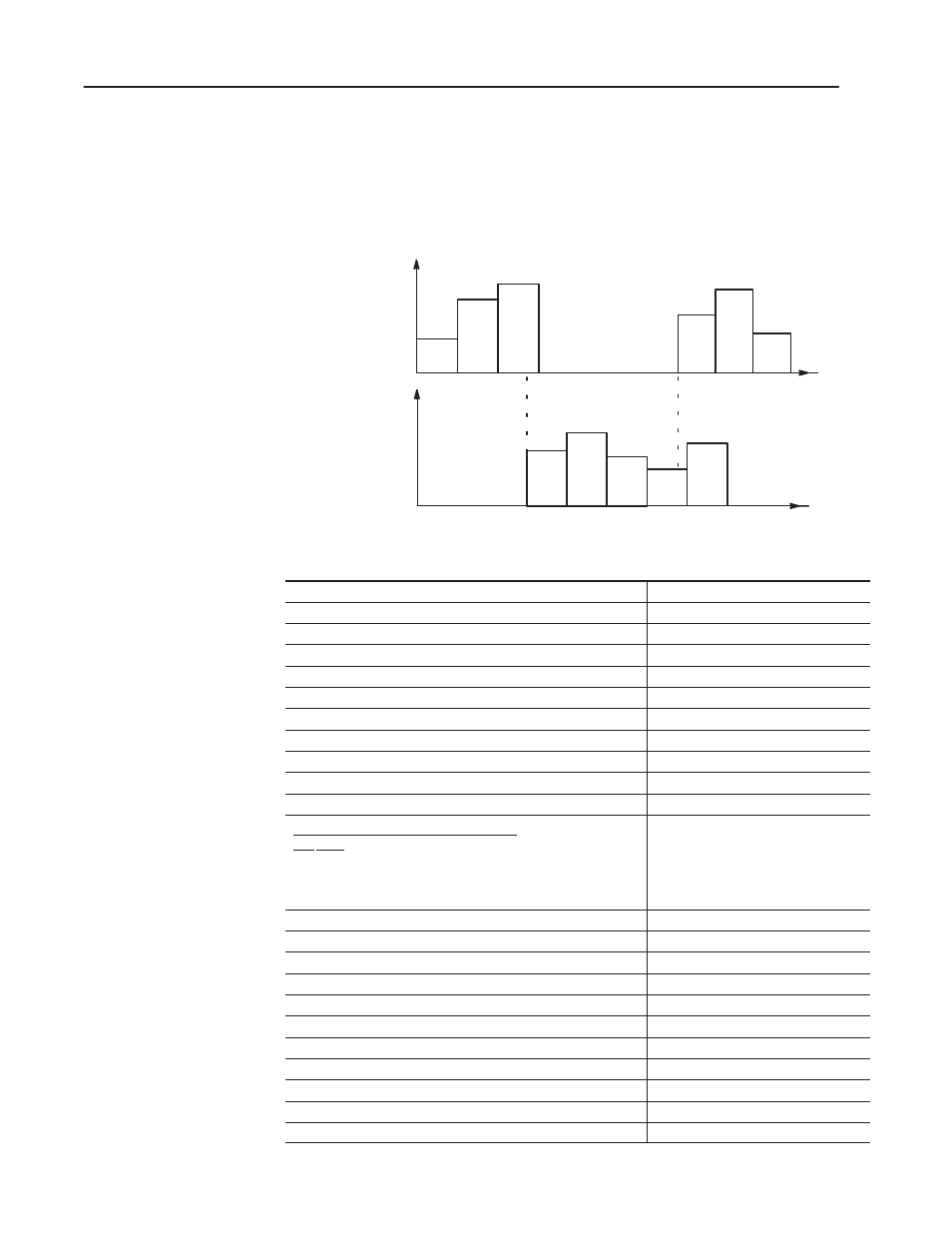

Co-injection Diagram for ABA

QI(A)’s Injection Profile

aaa

1

2

3

4

5

6

2

3

1

QI(B)’s Injection Profile

0

bbb

4

5

0

Pressure

Pressure

Time

Time

Suspended til other

reaches position aaa

stored in IPCB08

Suspended til other

reaches position bbb

stored in IPC08.

List of Co-injection Parameters for ABA

Description (for suspension of injection profile):

with Word/Bit:

start injection sequence

DYC02-BO4 = 1 or DYCB02-BO4 = 1

enable suspension at start (Start at opposite screw position IPC08.)

DYCB03-BO4 = 1

disable automatic sequence into pack/hold

IPCB02-B08 = 1

enable own suspension on own screw position IPC56

IPC02-B10 = 1

optional time delay after reaching opposite screw position

IPC07 and IPCB07

screw position of other to exit suspension

IPCB08 = aaa or IPC08 = bbb

set-outputs during injection

INC09-16 or INCB09-16

set outputs during pause before other goes automatically to P/H

INCB33-36

set-outputs during suspended injection

INC61-64

screw position of own to start suspension

IPC56 = aaa

set-output mode during suspended injection

B12 B11 (IPC54 or 55 overrides corresponding value in INC61-64)

0 0

=

apply

all four set-outputs stored in INC61-64

0

1

= control injection valve with pressure setpoint in IPC55

1

0

= control injection valve with velocity setpoint in IPC54

1

1

= error condition

IPC02-B12, B11

IPCB02-B12, B11

velocity setpoint for closed-loop control during suspended injection

IPC54

pressure setpoint for closed-loop control during suspended injection

IPC55

time limit for injection transition (indicated by IPS06.B00)

IPC60 & IPCB60

screw position limit for injection transition (indicated by IPS06.B01)

IPC61 & IPCB61

screw pressure limit for injection transition (indicated by IPS06.B02)

IPC62 & IPCB62

cavity pressure limit for injection transition (indicated by IPS06.B03)

IPC63 & IPCB63

status bit: injection profile complete

SYS02-B04

status bit: injection suspended

SYS03-B00

status bits: handshaking for change-over of input #3

SYS14-B14, -B15

status bit: injection profile in progress

SYS21-B04

status bit: end of injection profile, set-outputs in progress

SYS22-B04

Flow Chart for

Co-injection Programming