Vcc5_sby routing, Power state and reset signal routing – Kontron COMe Starterkit Eval T2 User Manual

Page 168

Power and Reset

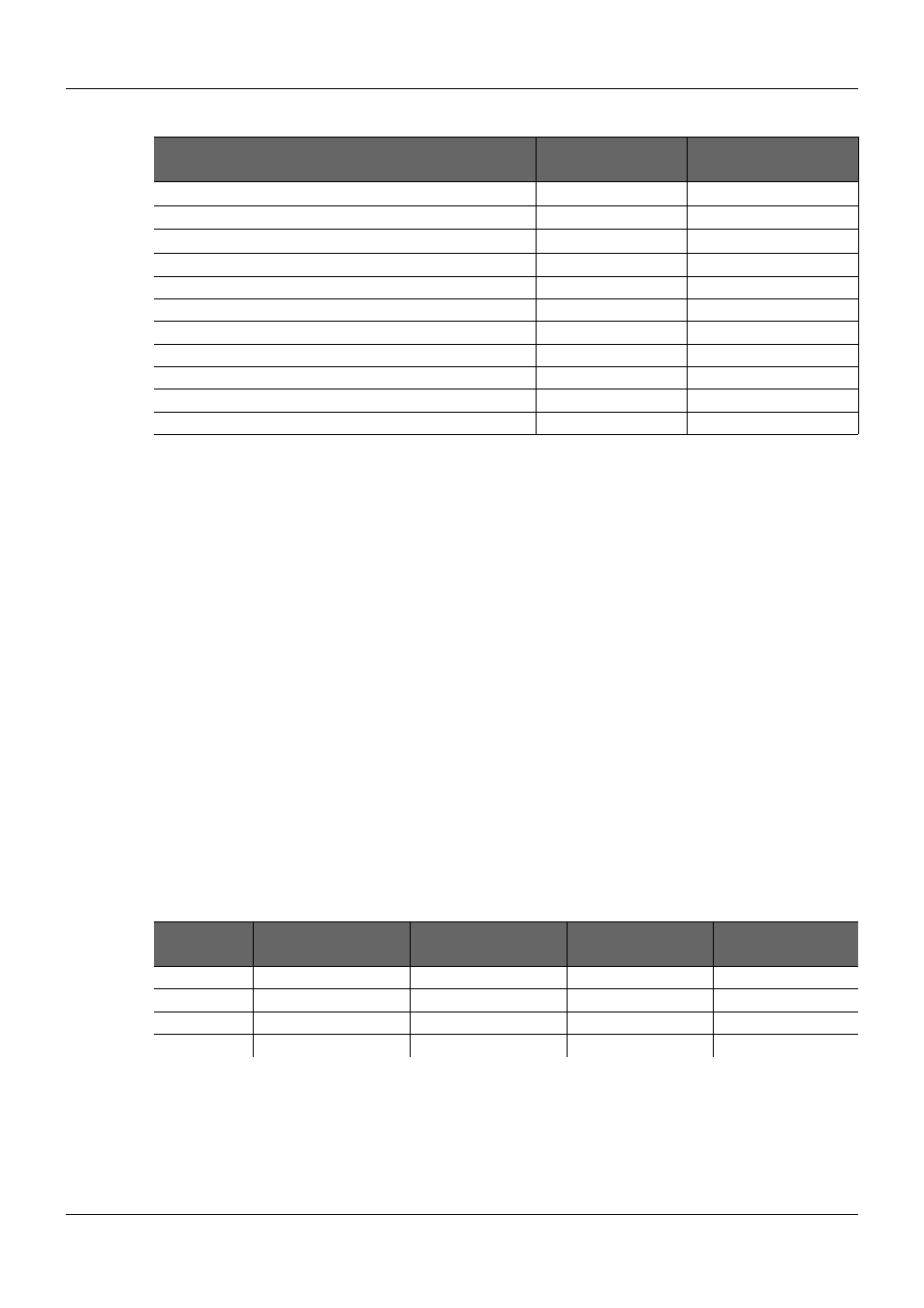

Table 56:

Approximate Copper Trace Current Capability per IPC-2221 Charts

Trace Type

Max Current with

10°C Temp Rise

Max Current with

20°C Temp Rise

100 mil wide internal trace ½ ounce/ 17μm base copper

1.3 A

1.8 A

200 mil wide internal trace ½ ounce/ 17μm base copper

2.0 A

3.0 A

400 mil wide internal trace ½ ounce/ 17μm base copper

3.5 A

5.0 A

100 mil wide internal trace 1 ounce/ 35μm base copper

2.1 A

3.0 A

200 mil wide internal trace 1 ounce/ 35μm base copper

3.5 A

5.2 A

400 mil wide internal trace 1 ounce/ 35μm base copper

6.0 A

8.0 A

100 mil wide external trace ½ ounce/ 17μm base copper

2.4 A

3.4 A

200 mil wide external trace ½ ounce/ 17μm base copper

4.0 A

5.5 A

400 mil wide external trace ½ ounce/ 17μm base copper

7.0 A

10.0 A

3.5.3.

VCC5_SBY Routing

The +5V Suspend power rail, if used, should be sized to handle 2A. Most, but not all, Modules

will use considerably less than 2A for this power rail. Modules with multiple Ethernet channels

and wake-on-LAN capability will use more current. The COM Express Specification allows up to

2A on this rail.

3.5.4.

Power State and Reset Signal Routing

Power state and reset signals are single-ended signals that do not have any particular routing

constraints.

To utilize the full functionality of PCI Express devices on the COM Express Carrier Board, some

additional supply voltages are necessary besides the standard supply voltages of the ATX power

supply. Many PCI Express devices are capable of generating wake up events during Suspend

operation; for example an external PCI Express Ethernet device that supports 'Wake On LAN'

functionality. Therefore, it is necessary to generate an additional 3.3V Suspend voltage on the

Carrier Board to supply such devices during Suspend operation. The voltage regulator must be

designed to meet the power requirements of the connected devices.

The PCI Express specification defines maximum power requirements for the different PCI

Express connectors and/or devices. The power supply for the Carrier Board must be designed to

meet these maximum power requirements. Table 57 below shows the maximum current

consumption defined for the different types of PCI Express connectors.

Table 57:

PCIe Connector Power and Bulk Decoupling Requirements

Power Rail

PCIe x1, x4 or x8

Connector

PCIe x16

Connector

ExpressCard

Connector

PCIe Mini Card

Connector

VCC_12V

2.1A @ 1000uF bulk

5.5A @ 2000uF bulk

VCC_3V3

3.0A @ 1000uF bulk

3.0A @ 1000uF bulk

1.35A

-

VCC_3V3_SB

375mA @ 150uF bulk

375mA @ 150uF bulk

275mA

2.75A

VCC_1V5

750mA

500mA

PICMG

®

COM Express

®

Carrier Board Design Guide

Rev. 2.0 / December 6, 2013

168/218