Rockwell Automation FlexPak 3000 Digital DC Drive Version 4.3 User Manual

Page 141

Troubleshooting the FlexPak 3000 Drive

13-9

F01000 to

F01999

MICROBUS

FAULT

An error occurred on the Microbus.

Possible causes:

•

Electrical noise due to improper wiring practices or unsuppressed brake

coils, relays, or contactors.

•

Disconnected, loosely connected or damaged Microbus ribbon cable.

•

Defective Regulator board.

•

F01000-F01799: Defective Microbus peripheral or Regulator board.

•

F01810-F01816: A Microbus peripheral was found that is not supported

by the regulator software.

F00999

and

F02000 to

F03999

MICROPROCESSOR

HW

/

SW

FAULT

A microprocessor hardware or software fault occurred.

Possible causes:

•

Electrical noise due to improper wiring practices or unsuppressed break

coils, relays, contactors.

•

Defective Regulator board.

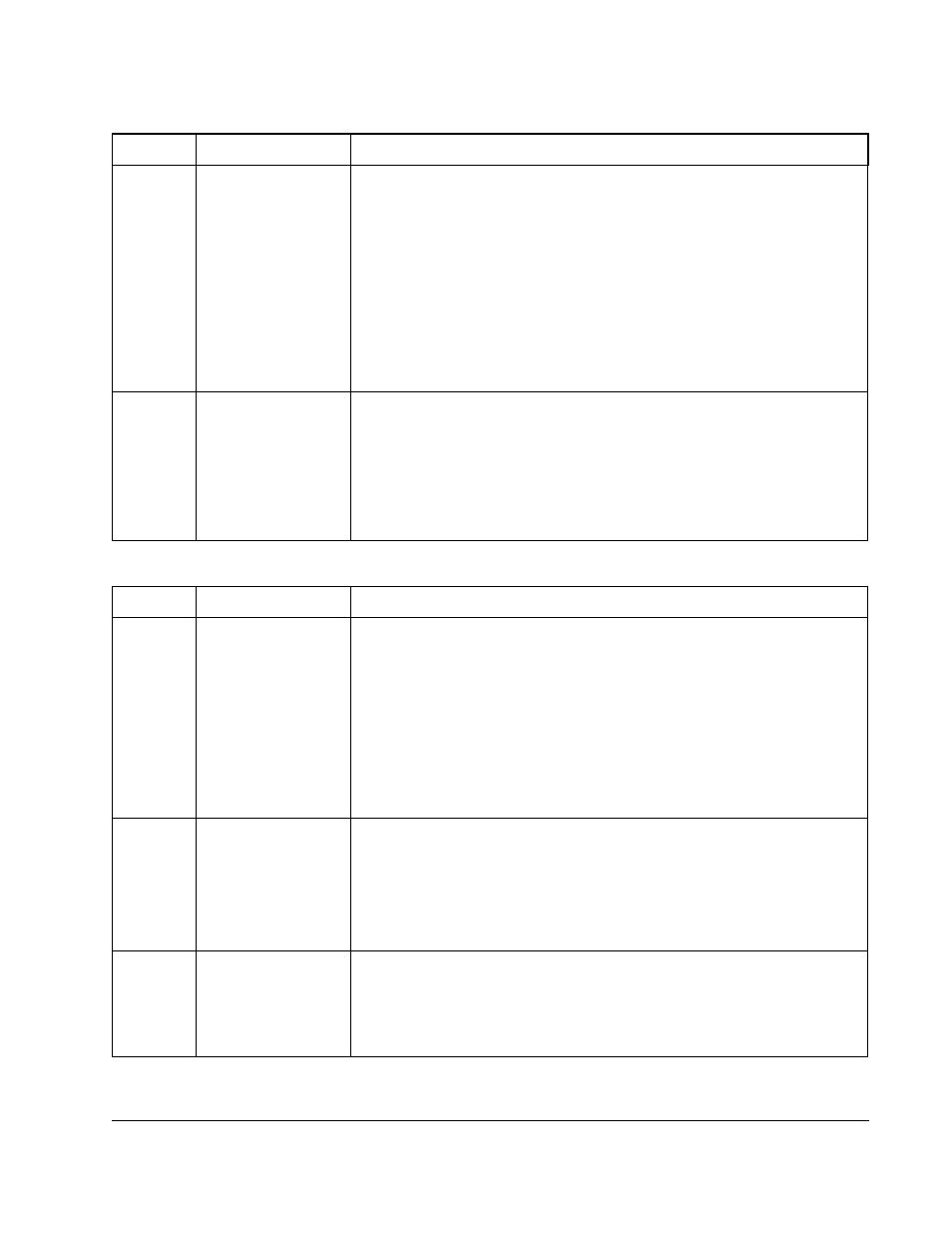

Table 13.2 – Alarm Codes

Code

Display

Description

A00001

MOTOR

BRUSH

WEAR

LOW

The motor brush wear detector indicates that the brushes are worn and

require replacement. If a motor brush wear detector is not used,

customer terminal strip terminals 12 and 14 must be jumpered to inhibit

this alarm when

DIG

IN

0

SELECT

(P.428) is set to

BRUSH

WEAR

.

Possible causes:

•

Worn motor brushes.

•

Disconnected, loosely connected, or damaged motor brush wear

indicator wiring.

•

Motor brush wear indicator failure.

A00002

AC

LINE

VOLTAGE

LOW

The AC line voltage fell below 90% of

NOMINAL

AC

LINE

VOLTS

(P.307).

Possible causes:

•

Low AC line voltage.

•

Incorrect value entered for

NOMINAL

AC

LINE

VOLTS

(P.307).

•

Blown AC line fuse(s).

A00003

AC

LINE

VOLTAGE

HIGH

The AC line voltage rose above 115% of

NOMINAL

AC

LINE

VOLTS

(P.307).

Possible causes:

•

High AC line voltage.

•

Incorrect value entered for

NOMINAL

AC

LINE

VOLTS

(P.307).

Table 13.1 – Fault Codes (Continued)

Code

OIM Display

Description