P.801), P.803), 2 configuring the outer control loop forward path – Rockwell Automation FlexPak 3000 Digital DC Drive Version 4.3 User Manual

Page 100

9-6

FlexPak 3000 DC Drive Software Reference

9.2.2 Configuring the Outer Control Loop Forward Path

The difference between the

OCL

RAMP

OUTPUT

(P.846) and

OCL

feedback signal (after

lead/lag has been applied, if selected) is summed with the

OCL

feedback and then fed

into a

PI

block. In the

PI

block, gain (

OCL

PI

PROP

GAIN

(P.808)) and lead frequency (

OCL

PI

LEAD

FREQ

(P.809)) are applied. The output of the

PI

block is clamped within the

values of

OCL

PI

POSITIVE

LIMIT

(P.810) and

OCL

PI

NEGATIVE

LIMIT

(P.811).

The signal from the

PI

block is fed into the

OCL

trim range block. Trim determines the

amount of control the

OCL

signal has on the speed/voltage loop reference. The amount

of trim is set through

OCL

TRIM

RANGE

(P.812).

OCL

REF

REGISTER

(P.801)

The reference for the

outer control loop that

is used when

OCL

REFERENCE

SELECT

(P.800) is set to

REGISTER

.

Parameter Range:

–4095 to 4095

Default Setting:

0

Parameter Type:

Tunable

OIM Menu Path(s):

Outer Control Loop (

OCL

) -

OCL

Configure

Typically used in applications where a constant reference is needed.

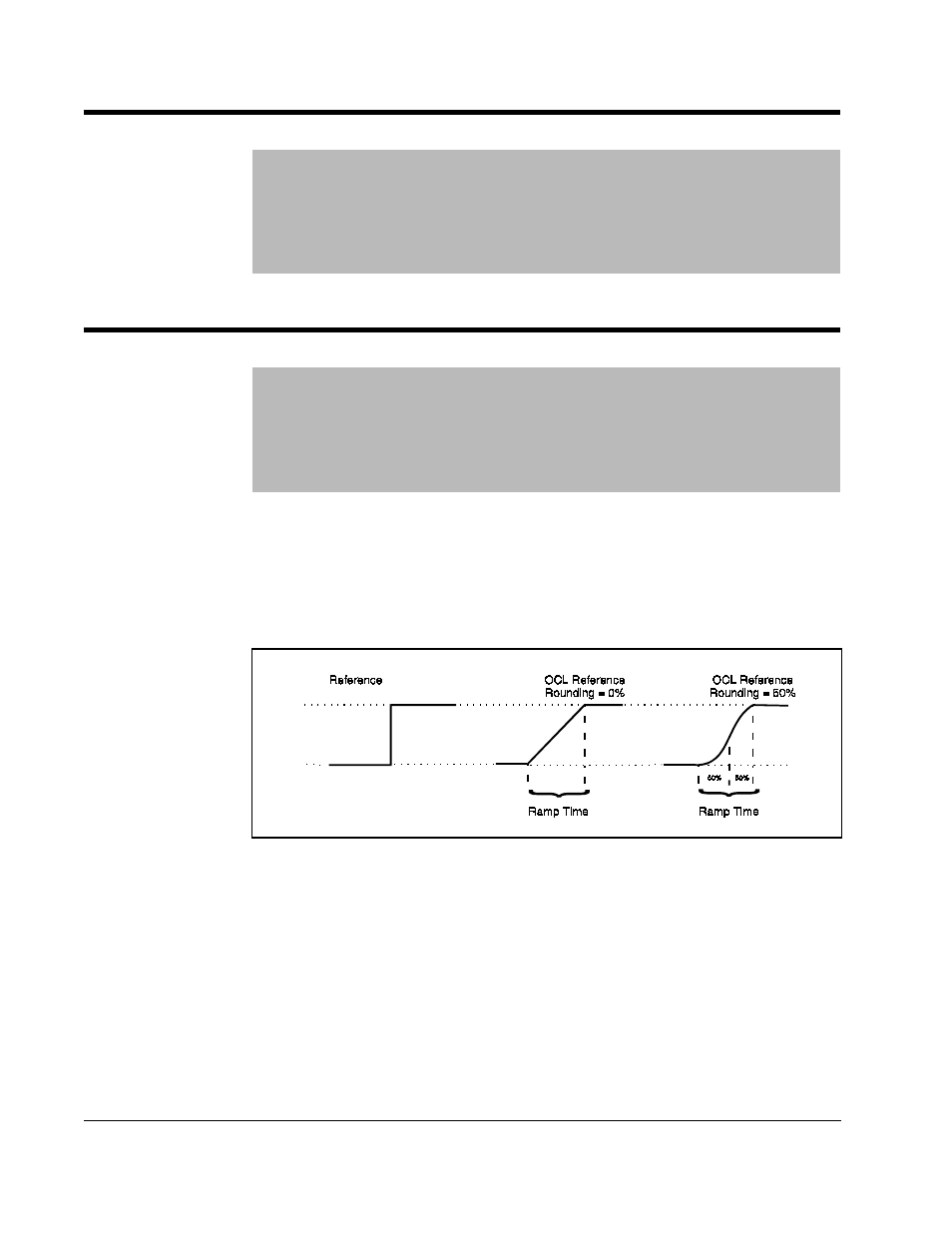

OCL

REF

ROUNDING

(P.803)

Specifies the amount

of reference

smoothing (rounding)

for the outer control

loop.

Parameter Range:

0 to 50%

Default Setting:

0%

Parameter Type:

Tunable

OIM Menu Path(s):

Outer Control Loop (

OCL

) -

OCL

Tuning

It is set as a percentage of

OCL

REF

RAMP

TIME

. Rounding is performed at the

beginning and end of an

OCL

reference change.

If

OCL

REF

ROUNDING

is set to 0%, the

OCL

performs a linear ramp function. If it is set

to 50%, the entire ramp time is smoothed: 50% at the beginning of the reference

change and 50% at the end. If

OCL

REF

RAMP

TIME

(P.802) is 0.0 (S-curve block

bypassed),

OCL

REF

ROUNDING

has no effect on the

OCL

reference signal.

Figure 9.3 – OCL Reference Signal Rounding