Rockwell Automation FlexPak 3000 Digital DC Drive Version 4.3 User Manual

Page 135

Troubleshooting the FlexPak 3000 Drive

13-3

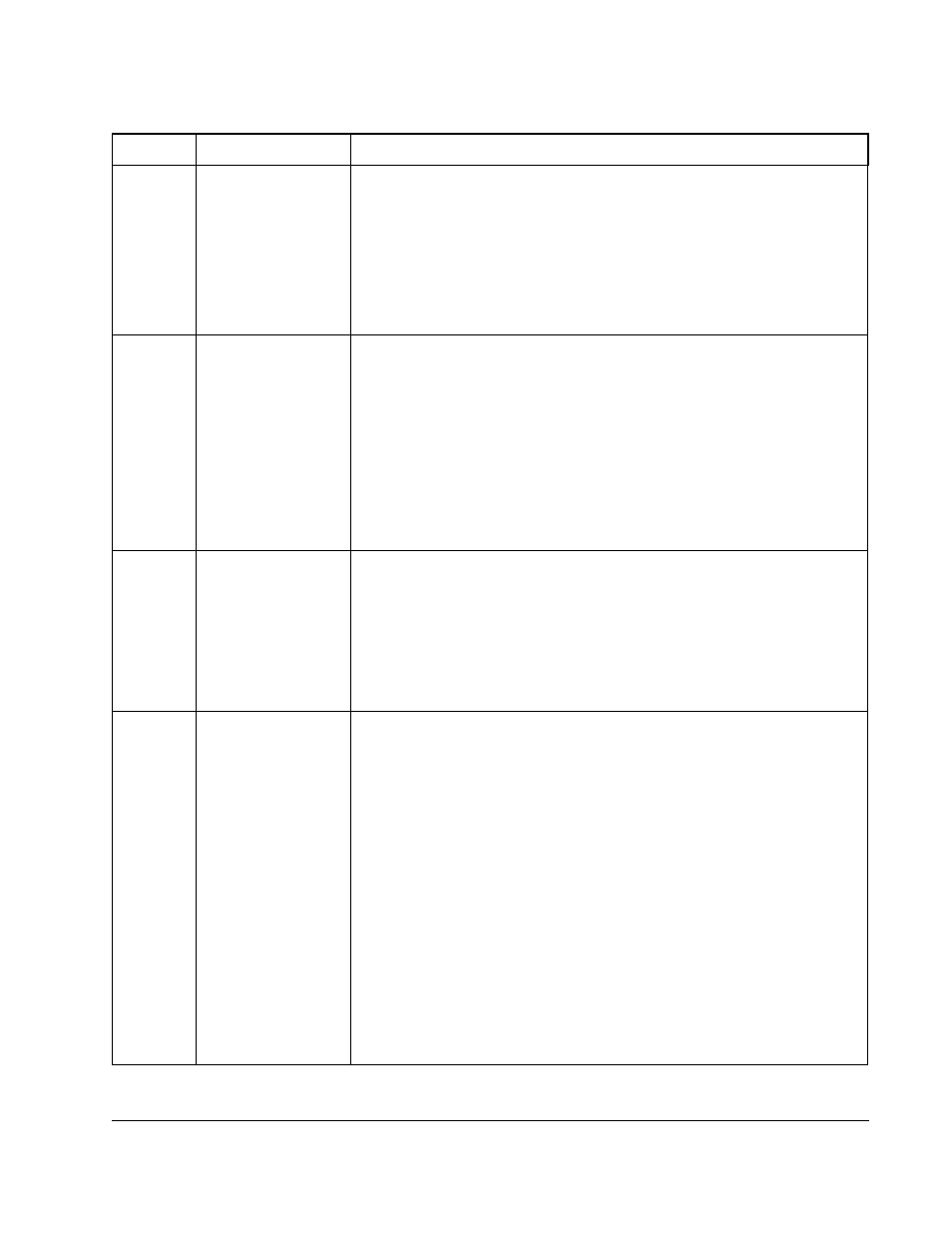

F00005

SUSTAINED

OVERLOAD

Inverse time overload circuit trip.

Possible causes:

•

Incorrect armature current feedback scaling (

MOTOR

RATED

ARM

AMPS

,

MAXIMUM

CURRENT

,

CT

TURNS

RATIO

, and/or J18 not set properly).

•

Blown field supply fuse(s).

•

Mechanical binding preventing the motor shaft from rotating freely.

F00006

BLOWER

MOTOR

STARTER

OPEN

The blower motor starter is open. If a blower motor starter kit is not

installed, connector P8 must be fitted with the proper substitute connector

to inhibit this fault.

Possible causes:

•

Blown blower motor starter fuse(s).

•

Disconnected, loosely connected, or damaged blower motor starter

wiring.

•

Blower motor overload.

F00007

OPEN

ARMATURE

The motor armature circuit is open.

Possible causes:

•

Motor armature winding not connected or open circuit.

•

Blown inverting fault (DC) fuse.

•

Inverting fault breaker tripped.

F00008

MOTOR

THERMOSTAT

TRIP

Motor thermostat indicates high temperature. If a motor thermostat is not

used, customer terminal board pins 13 and 14 must be jumpered to inhibit

this fault.

Possible causes:

•

Damaged or disconnected motor thermostat wiring.

•

Inadequate ventilation.

•

Blower motor failure.

•

Incorrect blower rotation.

•

Blocked ventilation slots.

•

Clogged filters.

•

Excessive armature current.

•

One or more thyristors not operating.

Table 13.1 – Fault Codes (Continued)

Code

OIM Display

Description