Rockwell Automation 1397 DC Drive Firmware 2.xx User Manual

Page 97

4–25

Start–Up and Adjustment

Publication 1397-5.0 — June, 2001

!

ATTENTION: The Drive will not operate at the

correct speed if jumpers J11 and J14 are not set to the

correct positions. Failure to observe this precaution could

result in damage to, or destruction of, the equipment.

The expected analog tachometer voltage range can be set to a

maximum of 250 or 62V DC. Jumper J11 selects the hardware

circuitry to maximize the resolution over the entire speed range.

Table 4.I

Regulator Board Jumpers

Jumper J14

Jumper J11

Top Speed Tach Volts

≤ 16 Volts

Low

16

Top Speed Tach Volts

≤ 31 Volts

Low

31/125

Top Speed Tach Volts

≤ 62 Volts

Low

62/250

Top Speed Tach Volts

≤ 125 Volts

High

31/125

Top Speed Tach Volts

≤ 250 Volts

High

62/250

Note: The output voltage of the tachometer must not exceed 250 V for DC tachometers or 275 RMS for

AC tachometers when the motor is rotating at [Max Motor Speed]. To calculate the output

voltage at top speed, multiply the two parameter values:

Tach Voltage at [Max Motor Speed] = [Max Motor Speed]

× [Analog Tach v per thousand]

1000

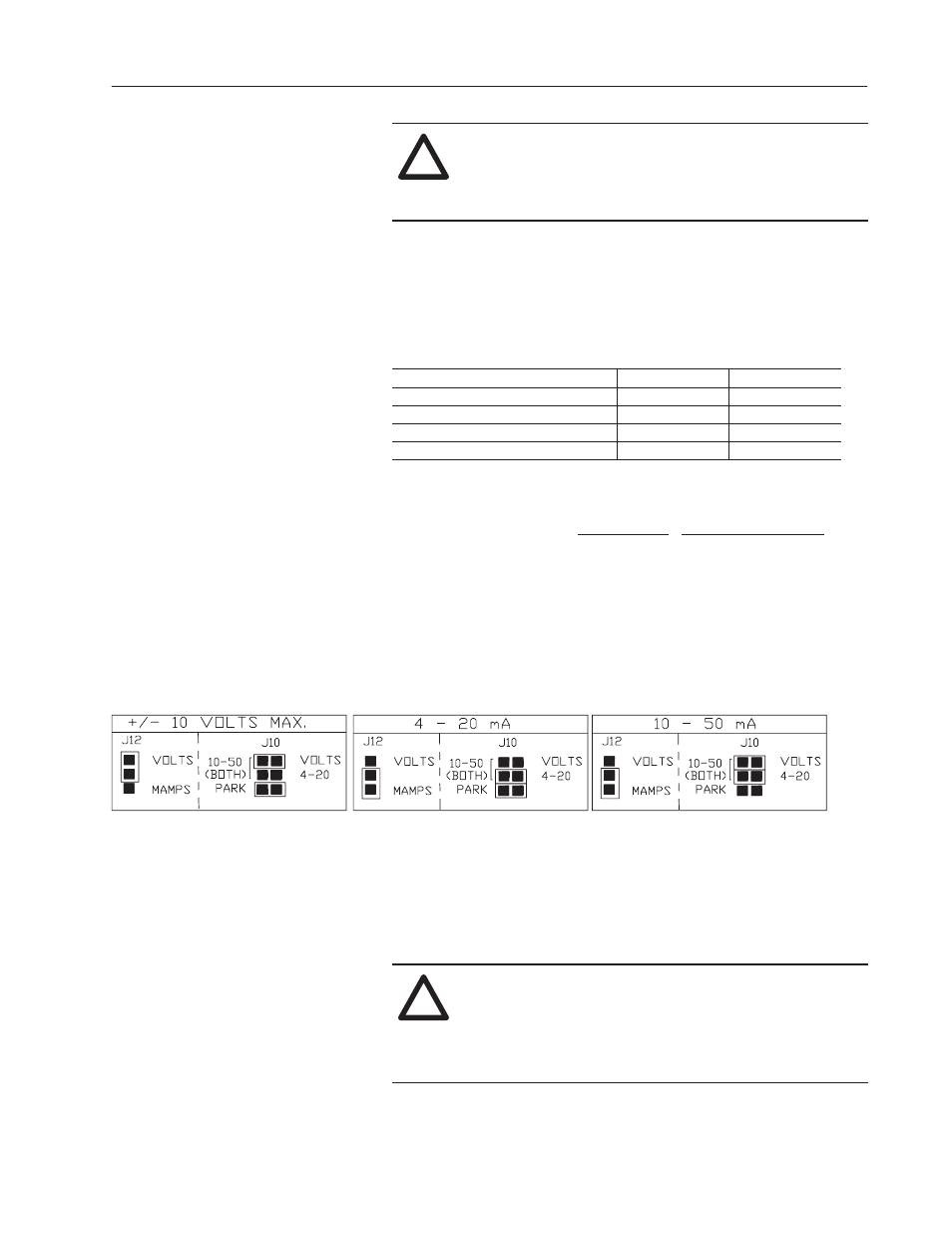

Analog Reference 1 Set–up (Jumpers J12, Autoref and J10, Autoref)

The Anlg In 1 jumpers (J12 and J10 Fig. 4.10) select the type of

analog reference to be used. J12 selects the type of signal (voltage or

milliamps). J10 selects the range.

Figure 4.10

Anlg In 1 Jumper Selection

Scaling the Armature Current Feedback (Jumper 18)

The Arm I FB RB jumper (J18) scales the armature current feedback

signal. The Drive calculates the value of the burden resistor needed

to scale the armature current feedback signal. The calculations are

based on the values of [Motor Arm Amps] (P.045 ) and Maximum

Current (P. 040).

!

ATTENTION: The Drive will not operate at the

correct speed if jumpers J10, J12 and J18 are not set to

the correct positions for your application. Failure to

observe this precaution could result in damage to, or

destruction of, the equipment.