Figure 2.25 wiring customer interlocks – Rockwell Automation 1397 DC Drive Firmware 2.xx User Manual

Page 54

2–36

Installation

Publication 1397-5.0 — June, 2001

Figure 2.24

CON 2 Terminal Strip 115 VAC Inputs

1

2

3

4

5

6

7

8

9

10

11 12

13 14

115V

HI L1

COAST

ST

OP

(IN6)

CUST

OMER

INTERLOCK (IN7)

115V

HI (L1)

RUN (IN1)

ST

OP (IN2)

JOG (IN3)

REV/FWD (IN4)

REF SELECT (IN5)

FAUL

T RESET (IN8)

115V HI (IN8)

BRUSH WEAR (IN9)

MOT

OR

THERMOST

A

T

(IN 10)

115V HI (L1)

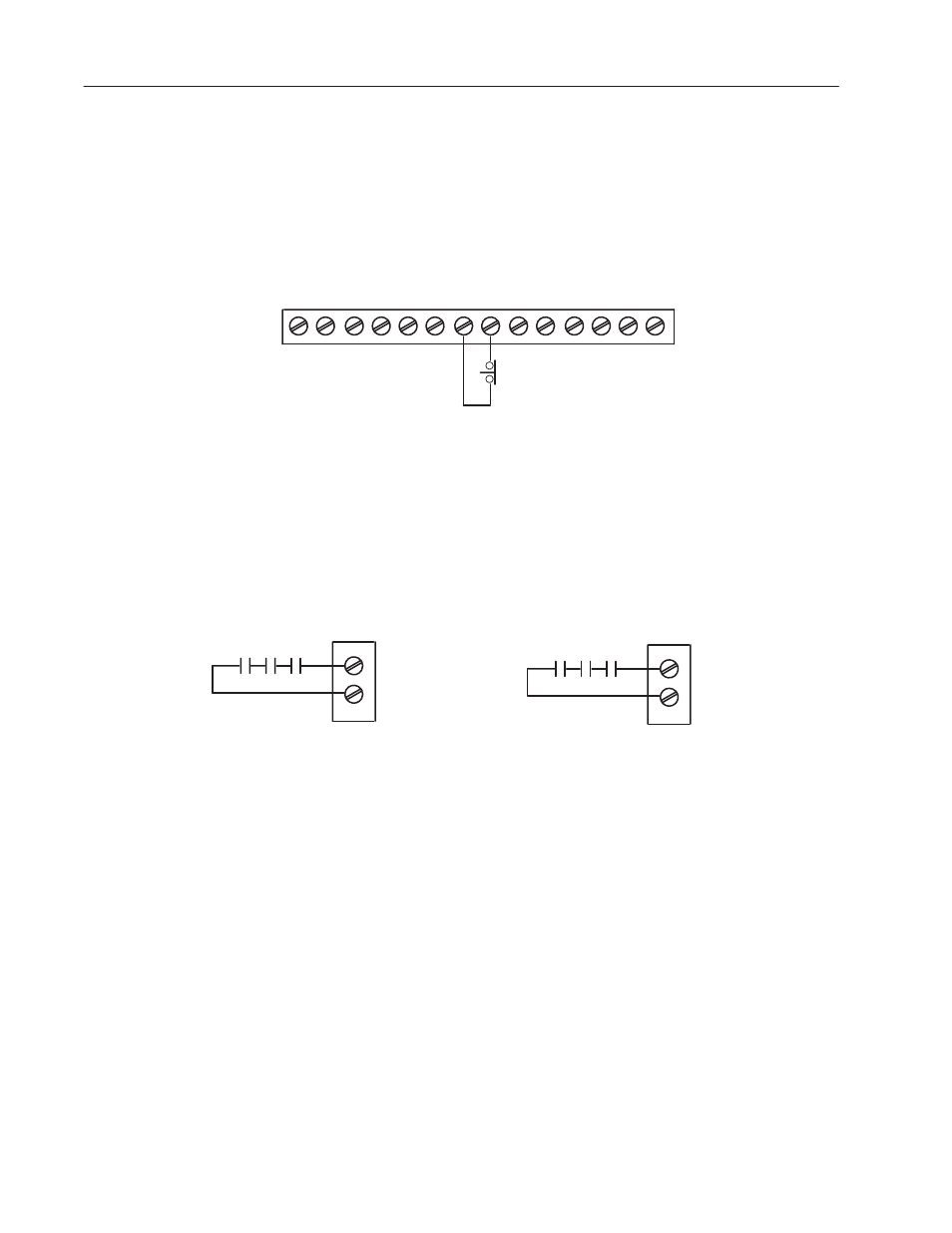

2. Wiring Customer Interlocks

Wire the Customer Interlock as shown in Figure 2.25. Both the 24V

Regulator Board Terminal Strip and the 115VAC CON2 Terminal

Strip utilize terminal #9 and #11 as the connection point for a

Customer Interlock. All customer interlocks must be closed for

Drive operation and CANNOT be masked.

Regulator Board Terminal Strip

24VDC Customer Interlock Circuit

9

11

115VAC Option Board CON 2

115VAC Customer Interlock Circuit

Figure 2.25

Wiring Customer Interlocks

9

11

Customer

Interlock (IN7)

115VAC Customer

Interlock Circuit

3. Wiring the Motor Thermostat/Brush Wear Circuits

Either a 24VDC or 115VAC input can be used to receive an external

voltage for a normally closed contact used in a motor thermostat

circuit. As shown in Figure 2.26, Terminal 13 is used for the motor

thermostat circuit on both 24VDC and 115VAC configurations. If

the motor thermostat circuit is open, the Drive will display a fault

and coast to a stop.

Terminal 12 is used for a level sensitive input that triggers a motor

brush wear alarm. The Drive will continue to operate under this

condition. Both the MOTOR BRUSH WEAR and MOTOR

THERMOSTAT inputs are always active and CANNOT be masked.