Rockwell Automation 1397 DC Drive Firmware 2.xx User Manual

Page 103

4–31

Start–Up and Adjustment

Publication 1397-5.0 — June, 2001

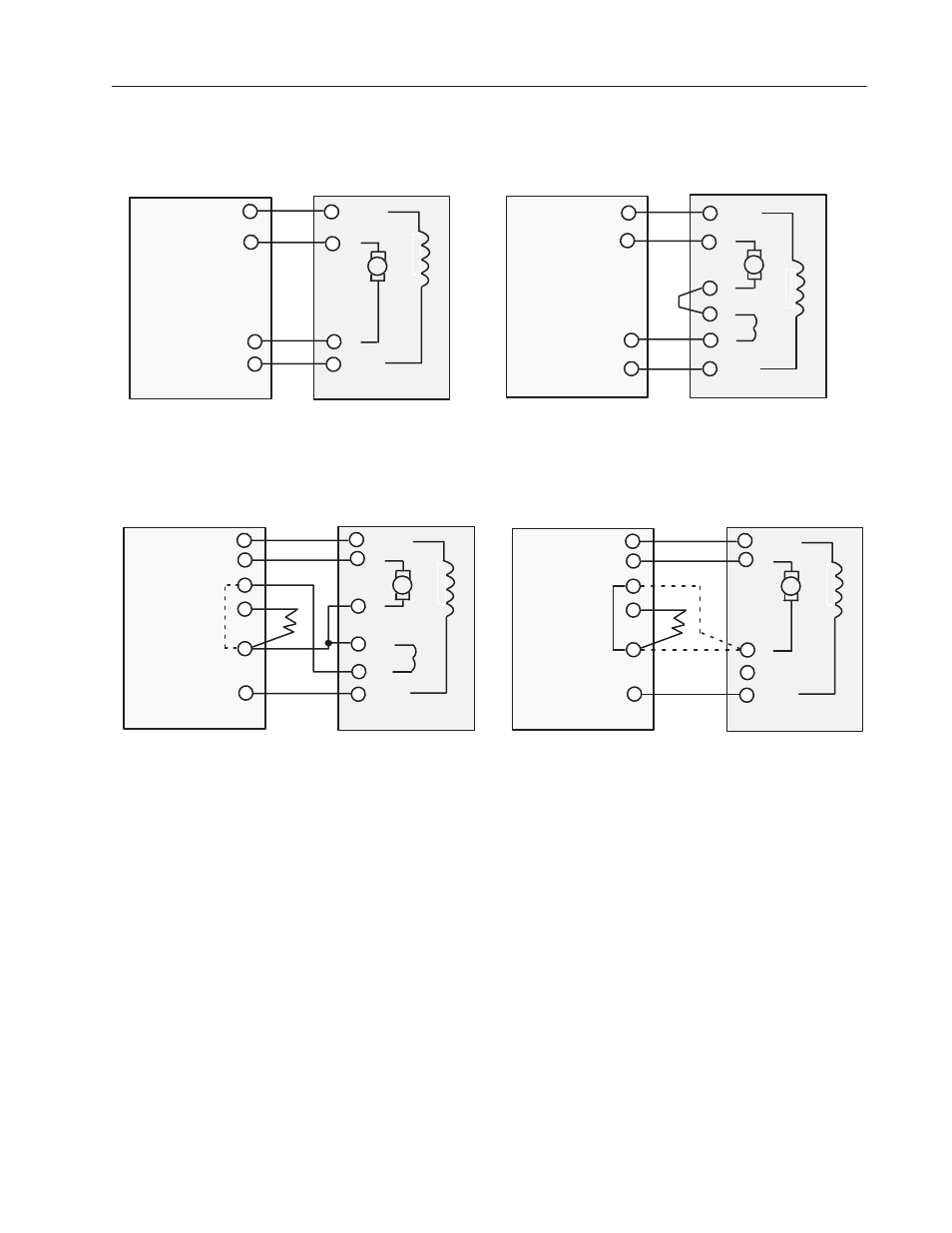

Figure 4.13

DC Motor Connections CCW Rotation

1.5 to 150 HP @ 230VAC

3 to 300 HP @ 460VAC

Bulletin 1397

F1 ( + )

Straight Shunt Machine,

CCW Rotation, Facing Commutator End

F1 ( + )

A1

A1

A2

F2 ( – )

( 2 )

Motor

( – ) 45

F2 ( – )

( 2 )

Bulletin 1397

F1 ( + )

Basic Stabilized Shunt Machine,

CCW Rotation, Facing Commutator End

F1 ( + )

A1

A1

A2

S1

S2

F2 ( – )

( 2 )

( 2 )

Motor

( – ) 45

F2 ( – )

Bulletin 1397

F1 ( + )

F1 ( + )

A1

A2

S2

F2 ( – )

( 2 )

Motor

A2/S1

F2 ( – )

( 2 )

S2

*

* If Used

DBR

S1

A2/S1–S2

Link

Removed

400 to 600 HP @ 460VAC

Bulletin 1397

F1 ( + )

Straight Shunt Machine,

CCW Rotation, Facing Commutator End

F1 ( + )

A1

A2

F2 ( – )

( 2 )

Motor

A2/S1

F2 ( – )

( 2 )

S2

*

* If Used

DBR

A2/S1–S2

Link

Removed

A1

( 3 )

2 – If this connection of the motor armature leads results

in motor rotation opposite of what is required,

reverse the A1 and A2 lead connections at the

motor.

3 – Connect Drive Terminal A2/S1 or S2 to Motor

Terminal A2.

Basic Stabilized Shunt Machine,

CCW Rotation, Facing Commutator End

9. Make certain power is turned off and locked out.

10. Switch armature leads connected A1 (+) and 45 ( – ). If it is

inconvenient to switch the armature leads, the field leads

connected at F1 and F2 may be switched instead on a straight

shunt motor only. Be sure to document the final connection.

11. Apply power to the Drive.

12. Repeat steps 6 and 7 and verify that the motor rotation is correct.

NOTE: If both the field and armature connections are reversed no

change in rotation direction will occur.