Rockwell Automation 1397 DC Drive Firmware 2.xx User Manual

Page 36

2–18

Installation

Publication 1397-5.0 — June, 2001

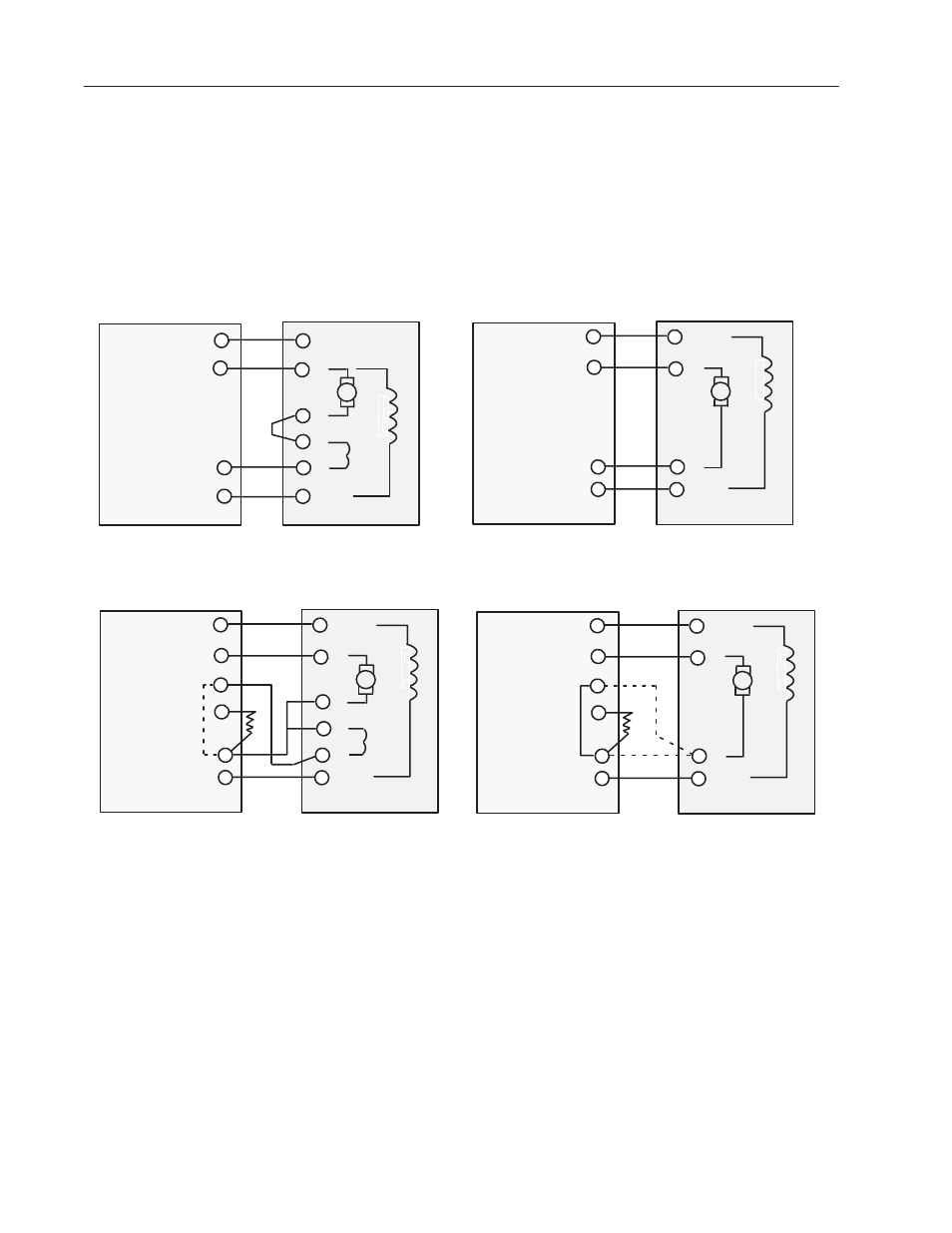

1.

Connect the motor armature and field leads to produce proper

direction of motor rotation. Figure 2.12 shows the connections

required to produce counterclockwise rotation of the motor

when viewed from the commutator end with a positive speed

reference input to the Drive.

Figure 2.12

Typical DC Motor Connections (CCW) Rotation

Bulletin 1397

F1 ( + )

Basic Stabilized Shunt Machine,

CCW Rotation, Facing Commutator End

1.5 to 150HP @ 230VAC, 3 to 300HP @ 460VAC

F1 ( + )

A1

A1

A2

S1

S2

F2 ( – )

( 2 )

( 2 )

Motor

(1)

Bulletin 1397

F1 ( + )

Straight Shunt Machine,

CCW Rotation, Facing Commutator End

F1 ( + )

A1

A1

A2

A2

F2 ( – )

( 2 )

Motor

(1)

( – ) 45

F2 ( – )

Basic Stabilized Shunt Machine,

CCW Rotation, Facing Commutator End

400 to 600HP @ 460VAC

Bulletin 1397

F1 ( + )

Straight Shunt Machine,

CCW Rotation, Facing Commutator End

F1 ( + )

A1

A1

A2

F2 ( – )

( 2 )

Motor

(1)

A2/S1

F2 ( – )

*

( 2 )

( 3 )

DBR

S1

Bulletin 1397

F1 ( + )

F1 ( + )

A1

A1

A2

F2 ( – )

( 2 )

Motor

(1)

A2/S1

F2 ( – )

*

( 2 )

DBR

S1

*If Used

(1) In cases where full regenerative torque capability is required for braking or slow down operation or where the drive

will be applied for bi–directional operation, you should specify straight shunt DC motors (wound without a series field winding)

to assure symmetrical motor operation in both forward and reverse directions, full torque capability, and motor stability under

any mode of operation.

(2) If this connection of the motor armature leads results in motor rotation opposite of what is required, reverse the A1 and A2

lead connections at the motor.

(3) Connect Drive Terminal A2/S1 or S2 to motor terminal A2.

( 2 )

A2/S1–S2

Link

Removed

A2/S1–S2

Link

Installed

( – ) 45

F2 ( – )

S2

S1

2.

The 1397 is supplied with semi conductor fuses for line

protection. An isolation transformer can also be used. In

general, the 1397 is suitable for direct connection to a correct

voltage AC line that has minimum impedance of 3%. If the