Table 2.b cable and wiring recommendations, Legend – Rockwell Automation 1397 DC Drive Firmware 2.xx User Manual

Page 34

2–16

Installation

Publication 1397-5.0 — June, 2001

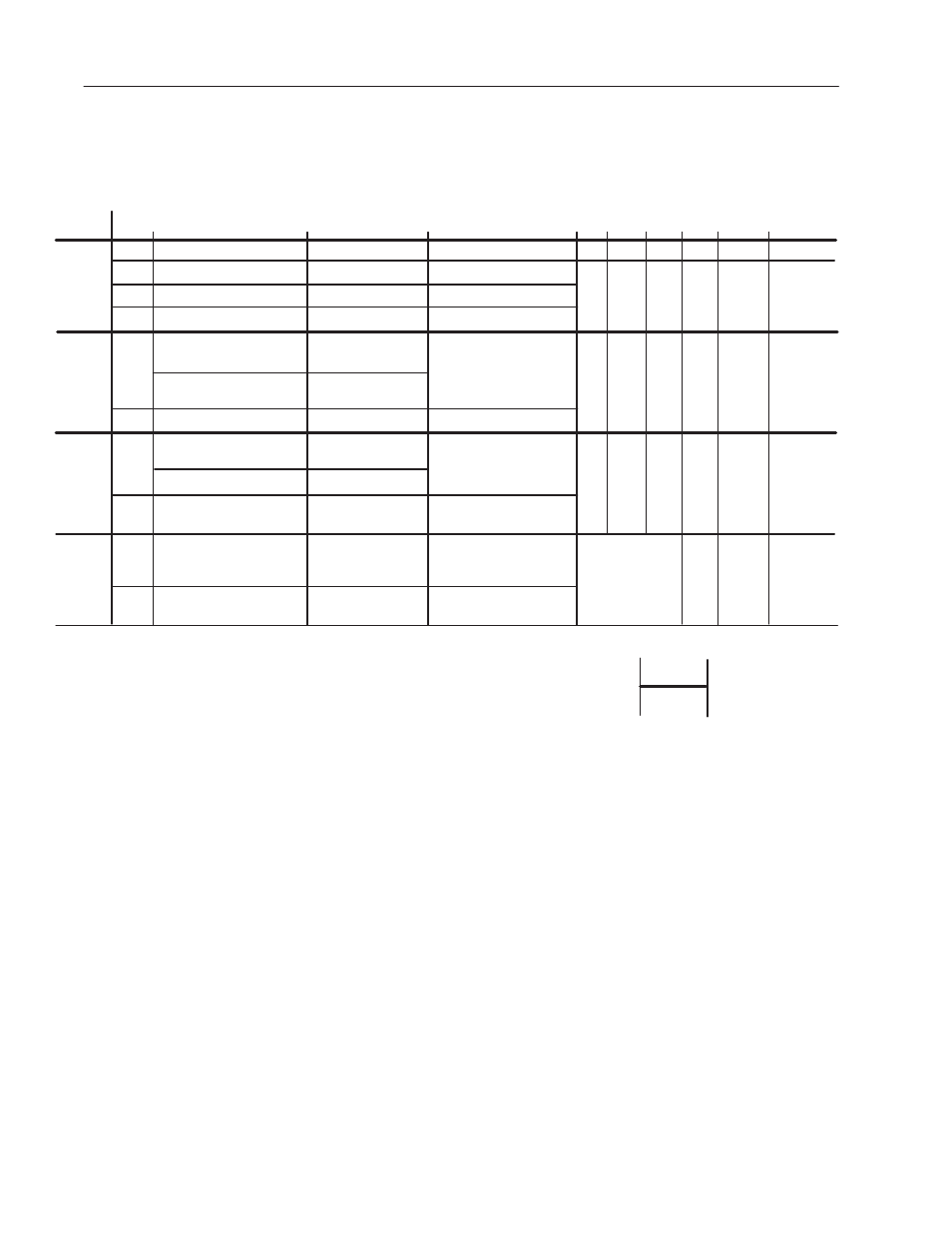

Table 2.B

Cable and Wiring Recommendations

Category

Power

Control

Signal

(Process)

Signal

(Comm)

Wiring

Class

1

2

3

4

5

Signal Definition

AC Power (600V or greater)

AC Power (less than 600V)

DC Power

DC Power

115V AC/DC Logic

115V AC Power

24V AC/DC Logic

Analog Signals,

DC Supplies

Digital (low speed)

Digital

(high speed)

Serial

Communication

Serial Communication

(greater than 20k baud)

Signal Examples

2.3kV 3/Ph AC Lines

460V 3/Ph AC Lines

DC Motor Armature

DC Motor Field

Relay Logic/PLC I/O

Motor Thermostat

Power Supplies,

Instruments

PLC I/O

Reference/Feedback

Signal, 5 to 24V DC

TTL

I/O, Encoder, Count

Pulse Tach

RS-232, 422 to

Terminals/Printers

PLC Remote I/O,

PLC Data Highway

Cable Type

per NEC & Local Codes

per NEC & Local Codes

per NEC & Local Codes

per NEC & Local Codes

per NEC & Local Codes

per NEC & Local Codes

Shielded Cable – Belden

8735, 8737, 8404

Shielded Cable – Belden

9728, 9730

Shielded Cable – Belden

RS-232 – 8735, 8737

RS-422 – 9729, 9730

Twinaxial Cable – Belden

9463, A-B 1770-CD

1

0

3/9

3/9

3/

18

2/3/4

3/9

0

3/6

3/

12

5/6

3/9

3/6

0

3/9

7/8

3/18

3/12

3/9

0

9/10/11

Note6

Note 6

Note 6

1/3

Spacing

Notes

1/2/5

1/2/5

1/2/5

Minimum Spacing in Inches between Classes –

Steel Conduit/Tray

Example: Spacing relationship between 480V AC incoming power leads and 24V DC logic leads.

– 480V AC leads are Class 2 ; 24V DC leads are Class 6

– For separate steel conduits, the conduits must be 3 inches (76 mm) apart

– In a cable tray, the two groups of leads are to be 6 inches (152 mm) apart

Spacing Notes:

1. Both outgoing and return current carrying conductors are to be pulled

in same conduit or laid adjacent in tray.

2.

Cables of the following classes can be grouped together.

A. Class 1; Equal to or above 601 volts

B. Classes 2,3, and 4 may have their respective circuits pulled in the

same conduit or layered in the same tray.

C. Classes 5 and 6 may have their respective circuits pulled in the

same conduit or layered in the same tray.

Note: Bundle may not exceed conditions of NEC 310

D. Classes7 and 8 may have their respective circuits pulled in the

same conduit or layered in the same tray.

Note: Encoder cables run in a bundle may experience some

amount of EMI coupling. The circuit application may dictate

separate spacing.

E.

Classes 9, 10 and 11 may have their respective circuits pulled in

the same conduit or layered in the same tray.

Communication cables run in a bundle may experience some

amount of EMI coupling and corresponding communication faults.

The application may dictate separate spacing.

3. All wires of class 7 thru 11 MUST be shielded per the

recommendations

4. In cable trays, steel separators are advisable between the class

groupings.

5. If conduit is used, it must be continuous and composed of magnetic

steel.

6. Spacing of communication cables classes 2 thru 6 is:

CONDUIT SPACING

THRU AIR

115 Volts – 1 inch

115 Volts – 2 inches

230 Volts – 1.5 inches

230 Volts – 4 inches

380/575 Volts – 3 inches

380/575 Volts – 8 inches

575 volts – proportional to 6”

575 volts proportional to 12”

per 1000 volts.

per 1000 volts

General Notes

1. Steel conduit is recommended for all wiring classes. (Classes 7-11).

2. Spacing shown between classes is the minimum required for parallel

runs less than 400 feet. Greater spacing should be used where

possible.

3. Shields for shielded cables must be connected at one end only. The

other end should be cut back and insulated. Shields for cables from a

cabinet to an external device must be connected at cabinet end.

Shields for cables from one cabinet to another must be connected at

the source end cabinet. Splicing of shielded cables, if absolutely

necessary, should be done so that shields remain continuous and

insulated from ground.

4. Power wire is selected by load. 16AWG is the minimum

recommended size for control wiring.

6

7

8

9

11

2/3/4/5

Note 6

1/3

0

LEGEND

2/3/4

Class Spacing

Steel Conduit/Tray

3/9