Motor and feedback polarity checks – Rockwell Automation 1397 DC Drive Firmware 2.xx User Manual

Page 101

4–29

Start–Up and Adjustment

Publication 1397-5.0 — June, 2001

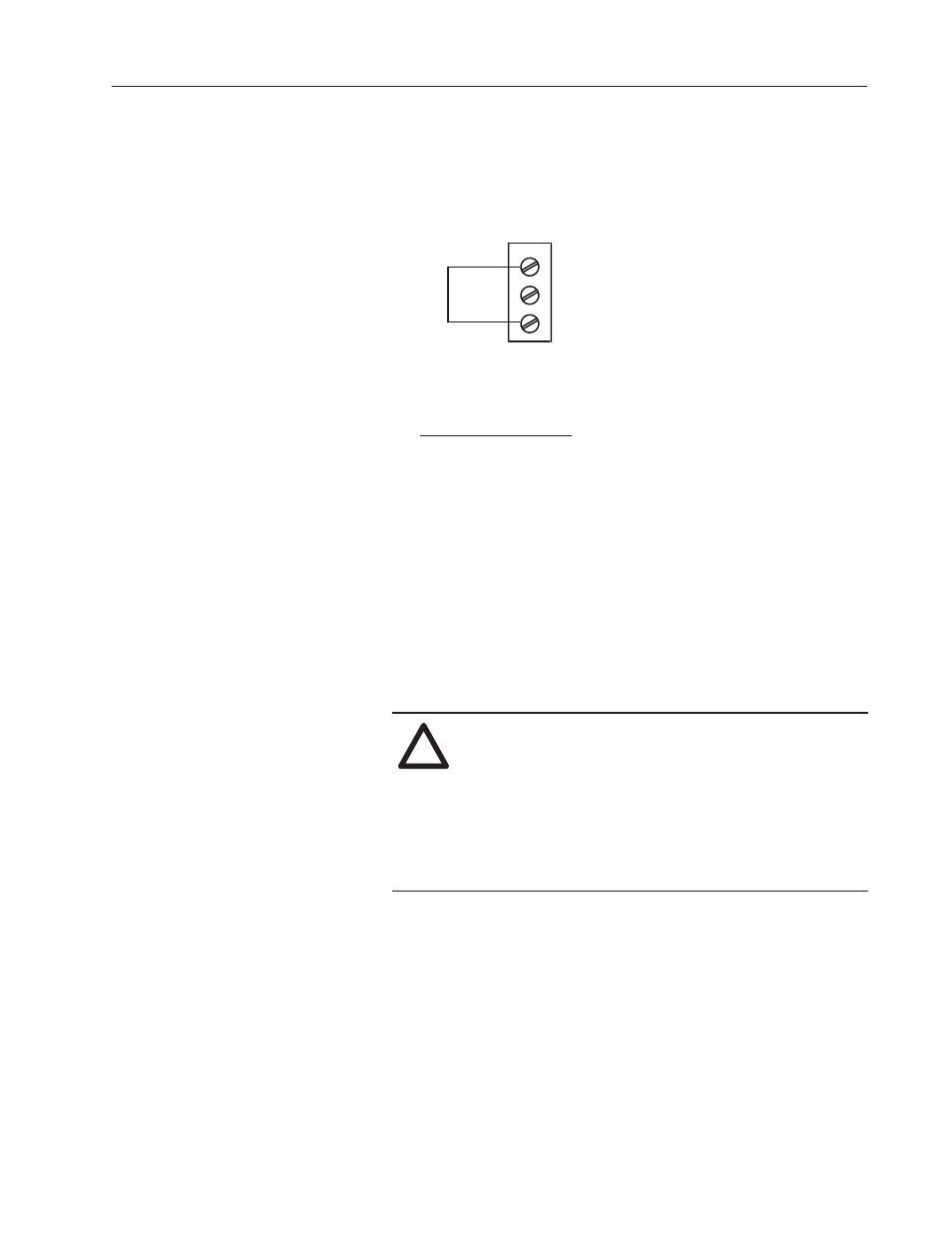

NOTE: If the DC motor used for this application doesn’t

possess a brush wear indicator, verify that terminals 12 and 14 of

the regulator board terminal strip are jumpered (Figure 4.12).

Regulator Board Terminal Strip

24VDC Brush Wear Circuit

12

13

14

BRUSH WEAR

MOTOR THERMOSTAT

+24V

Jumper here for

non–wear indicator

use

Figure 4.12

Brush Wear Option

7.

Other Standard Inputs – Other I/O may or may not be wired to

the Drive, depending on the application. The Drive may be

operated through the Human Interface Module (HIM) without

connecting the remaining I/O. Other inputs may be verified as

described in the preceding steps.

NOTE: If the Drive will be operated using a SCANport device

such as the Bulletin 1203-GD1/GK1, 1203-GD2/GK2,

1203-GK5, 1203-FB1 & FM1, or 1203 SM1 additional set–up

is required. See the chapter entitled Programming Parameters

and the installation manual of the specific SCANport device.

!

ATTENTION: Prior to running polarity checks, you

must provide a hard wired maintained external operator

accessible coast/stop pushbutton at regulator board

terminals 7 and 8 to disable the machine in case of

improper operation. Uncontrolled machine operation

can result if this is not done. Failure to observe this

precaution could result in severe bodily injury or loss

of life.

Motor and Feedback

Polarity Checks