Essential requirements for ce compliance, 30 installation/wiring – Rockwell Automation 22D PowerFlex 40P User Manual, FRN 3 User Manual

Page 40

1-30

Installation/Wiring

Essential Requirements for CE Compliance

Conditions 1-3 listed below must be satisfied for PowerFlex drives to

meet the requirements of EN61800-3.

1. Grounding as described in

for

additional grounding recommendations.

2. Output power, control (I/O) and signal wiring must be braided,

shielded cable with a coverage of 75% or better, metal conduit or

equivalent attenuation.

3. Allowable cable length in

is not exceeded.

Table 1.L Allowable Cable Length

(1)

Refer to

for details on optional external filters.

(2)

Equivalent to EN55011 Class A.

(3)

Equivalent to EN55011 Class B. To meet radiated emissions requirements for

EN61800-3 First Environment Unrestricted Distribution when communications is used,

ferrite cores need to be added to the communication lines. The recommended core is

Fair-Rite part number 0446176451 or Erocore part number FH29.7x13x25.9/FH1300 or

an equivalent core. The communication line must be wrapped a total of three times

around the core. Two cores may be needed depending on the thickness of the wire and

the core chosen. Both recommended cores are split-type and can be added to an

existing installation.

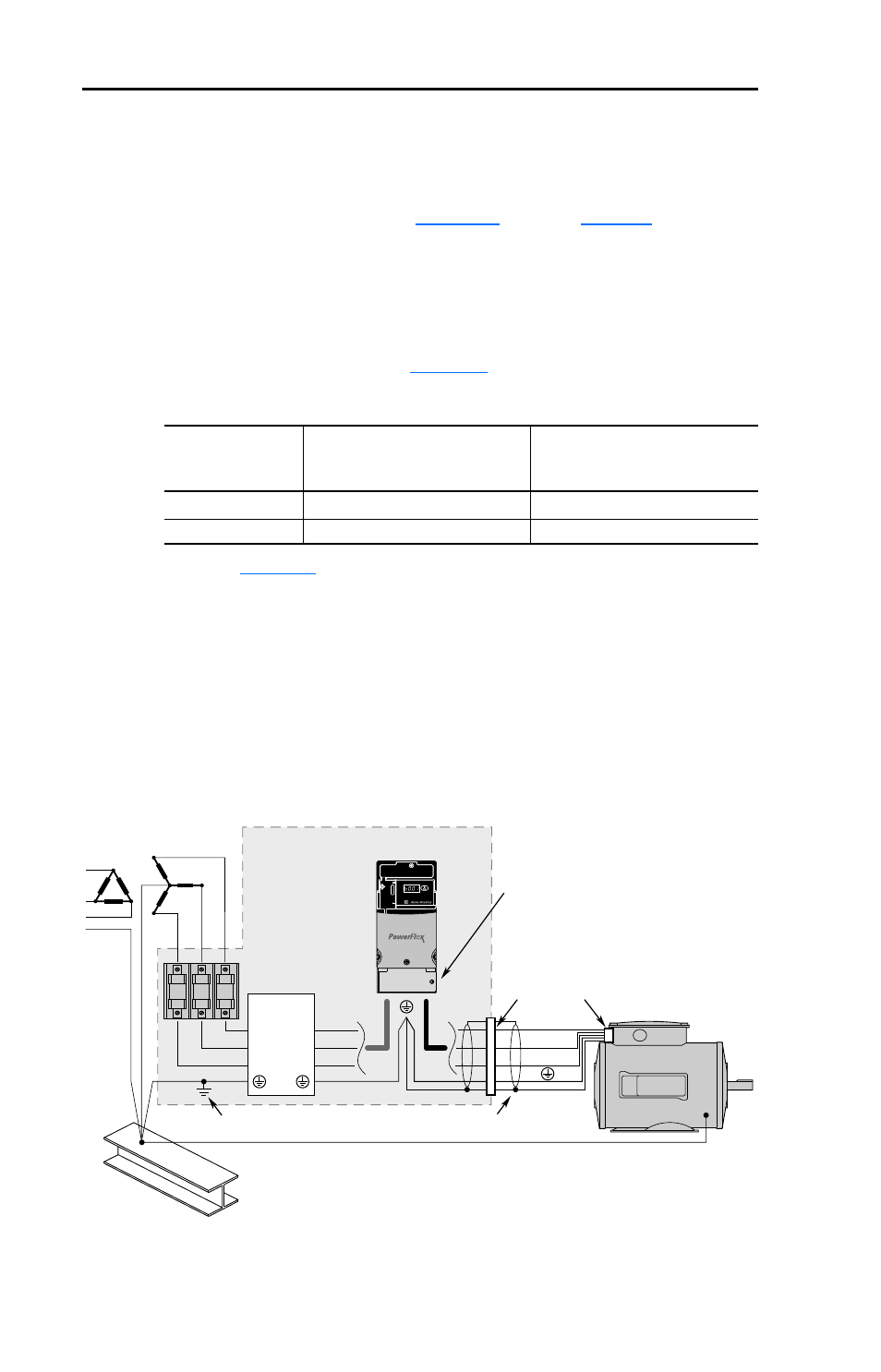

Figure 1.8 Connections and Grounding

(1)

First Environment Unrestricted Distribution installations require a shielded enclosure.

Keep wire length as short as possible between the enclosure entry point and the EMI

filter.

Filter Type

EN61800-3 First Environment

Restricted Distribution or

Second Environment

(2)

EN61800-3 First Environment

Unrestricted Distribution

(3)

External - S Type

(1)

10 meters (33 feet)

1 meter (3 feet)

External - L Type

(1)

100 meters (328 feet)

5 meters (16 feet)

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

EMI Fittings and Metal Conduit

IP 30/NEMA 1/UL Type 1

Option Kit

Shielded Enclosure

(1)

Building Structure Steel

Enclosure Ground Connection

EMI Filter

L1'

L2'

L3'

L1

L2

L3

Shielded Motor Cable