Profibus-dp network setup, Fig. 139: profibus logo, Initialization process – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 63: Profibus-dp .gsd file, Pre-initialization procedures, Profibus-dp network setup initialization process, Iguration - options/selecting view, E profibus network with trunk and drop lines - 49

49

Network

Installation

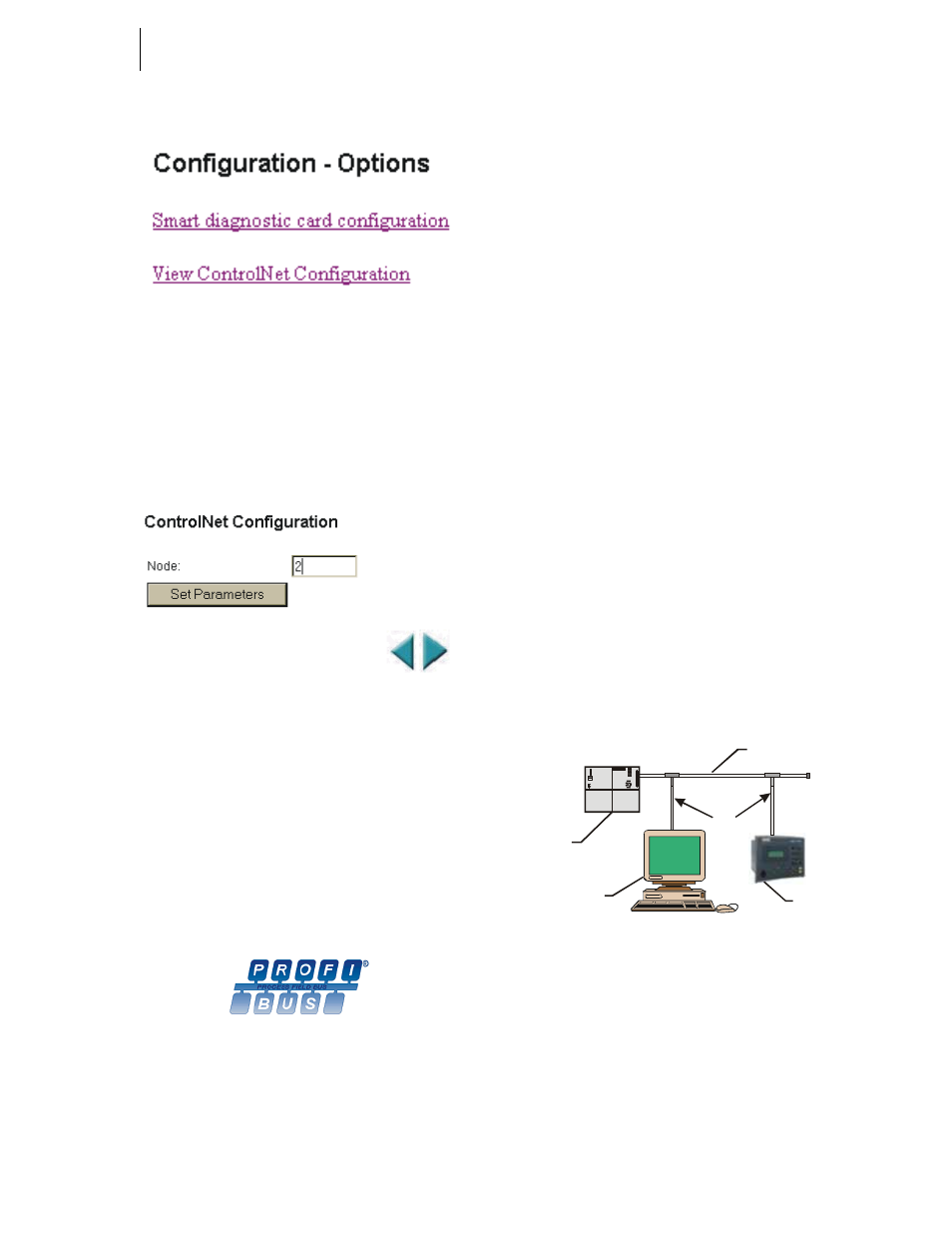

FIG. 137: CONFIGURATION - OPTIONS/SELECTING

VIEW CONTROLNET CONFIGURATION OPTION

Step 3. Click on View ControlNet Configuration. (See Fig.

137) The ControlNet Configuration Page appears.

(See Fig. 138)

FIG. 138: CONTROLNET CONFIGURATION PAGE/

SELECTING THE NODE ADDRESS

Step 4. Double Click in the Node: Text field. (See Fig. 138)

Enter the node address of this HI 3000 instrument.

(Node Address Range: 0-99)

Step 5. Click on Set Parameters. The Node address is set

for this instrument.

PROFIBUS-DP Network Setup

FIG. 139: PROFIBUS LOGO

NOTE:

Hardy Process Solutions is a member of Profibus

International.

Initialization Process

To be able to add an HI 3000 Series Instrument to a Profibus-

DP network, you need a PC and software such as Siemens

Step 7™, Simatic Manager or equal, that allows the Profi-

bus-DP PLC and the HI 3000 Series Instrument to exchange

data. Profibus Specifications are located in the Installation

and Service Manual for each HI 3000 Series Instrument.

Profibus-DP .GSD File

All devices connected to a Profibus-DP network requires a

*.gsd file. The *.gsd file contains all the parameters includ-

ing the baud rate, table formats and necessary data required

by the network PLC when an HI 3000 Series Instrument is

connected to the network.

A copy of the *.gsd file can be found on the CD that comes

with the instrument or at the Hardy Website or at http://

www.profibus.com/libraries.html.

Whichever Simatic Manager you select, you must go

through these three steps:

Step 1. Connect the HI 3000 Series Instrument to the Profi-

bus DP network and verify the address. (See Fig.

140) (Installation and Cabling Instructions are

located in the Cabling Section of this Manual)

Step 2. Connect the PC to the Trunk Line. Load the config-

uration properties to the initialization software on

the PC and transfer them to the PLC.

Step 3. Install the *.gsd file, and map I/O data table proper-

ties to the instrument.

FIG. 140: SIMPLE PROFIBUS NETWORK WITH

TRUNK AND DROP LINES

Pre-Initialization Procedures

Step 1. Inspect the network cables and make sure that the

cables have been installed correctly and satisfy the

Profibus-DP guidelines for the data transmission

baud rate(s) required. (See the Cabling Chapter/

Profibus Installation in this manual for Profibus-DP

cable specifications and cabling guidelines.)

24VDC

VOLTAGE

SELECTOR

RUN-P

RUN

STOP

MRES

SF

B ATF

D C5V

D C5V

FR CE

R UN

ST OP

C PU 315 -2 DP

SI EME NS

SIMATIC

Personal

Computer

Siemens

PLC

HI 3000

Series Instrument

Trunk Line

Drop Lines