Monitoring weighing parameters, Short glossary of terms, Tare value – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 18: About cable termination, Dip switch settings, Installing the rio option board, Fig. 4: remote i/o option card, Minating switch for terminating last module, Emote i/o option card

HI-3000 Series

4

Operation and Installation

•

Evaluating Totalized Weight

•

Check Weighing

•

Weight Level Alarming

•

Condition Monitoring

NOTE:

The 3000 Series have 4 mappable outputs in the

HI 3010 FillerDispenser and HI 3030 Multi-

scale controller and up to seven (7) on some of

the other 3000 Series products.

Monitoring Weighing Parameters

The HI 3000 series weight controllers are capable of calcu-

lating five types of weight data, including the standard Gross

and Net weights. In addition to the standard Gross and Net

weights there are three options such as Peak Force, Totalized

Weight (block transfer only), and Rate-of-Change or mass

flow rate entering or leaving a vessel.

Short Glossary of Terms

1.

Gross Weight - is used to describe the total weight

of the container and the contents.

2.

Net Weight - is the weight of the contents of the

container only.

3.

Tare Value - The action of adjusting out the known

weight of the container from the total indicated

weight, so that the indicator reads weight directly.

4.

Dead Load - The weight of the vessel and other

equipment which will be ignored during zero cali-

bration.

Tare Value

Current Gross Weights become the Tare value by pushing

the Tare Push Button on the front panel of the HI 3000

instrument, remote functions contact closure, discrete write

or block transfer command by the PLC, or can be entered as

a numeric value via the keypad on the front panel of the HI

3000 Series instruments This new tare value is the reference

point for Net Weight.

TV = G - N

TV = Tare Value (weight)

G = Gross Weight

N = Net Weight

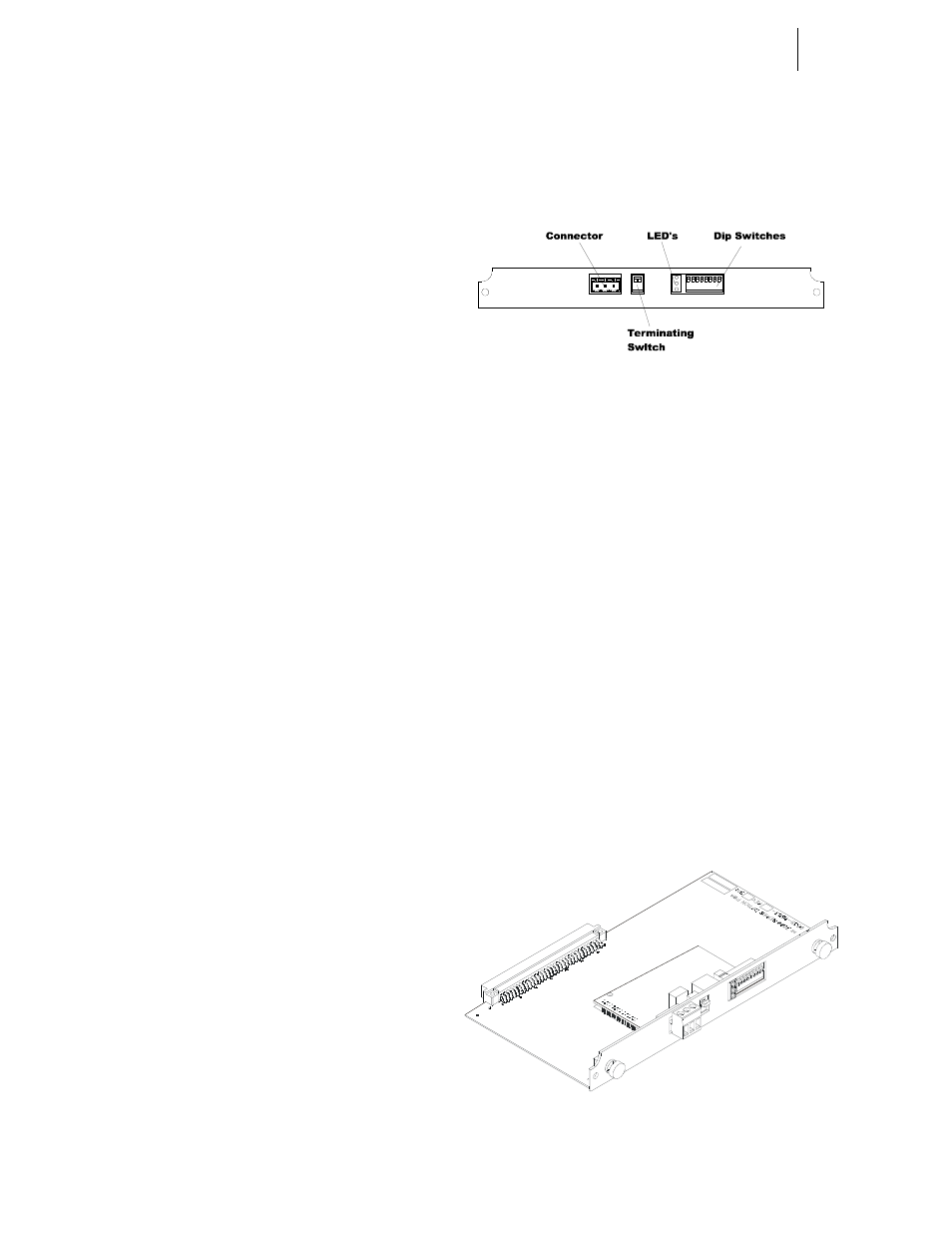

Remote I/O Board Cable Termination Dip Switch

Configuration

About Cable Termination

HI 3000 Series Remote I/O Modules are connected to a cable

in daisy-chain fashion and are referred to as “nodes”. A

Daisy Chain is a hardware configuration in which devices

are connected one to another in a series. The first and last

Remote I/O module must be terminated.

Step 1. The Terminating Switch is accessible from the rear

of the HI 3000 Series Module. (See Fig. 3)

FIG. 3: TERMINATING SWITCH FOR

TERMINATING LAST MODULE

Step 2. On the first module and the last module turn the ter-

minating switch to ON.

Step 3. For all other devices on the daisy chain the termi-

nating must be set to OFF.

Dip Switch Settings

Set all the Dip Switch Settings to ON. (See Fig. 3)

Installing the RIO Option Board

CAUTION: M

AKE

SURE

THAT

YOU

USE

AN

ANTI

-

STATIC

STRAP

WHEN

INSTALLING

THE

R

EMOTE

I/O O

PTION

C

ARD

.

Step 1. Position the RIO Option Card with the back plane

connector facing Option Slot #0. (See Fig. 4)

NOTE:

You can only use Option Slot #0 when installing

the RIO Option Card.

FIG. 4: REMOTE I/O OPTION CARD

Step 2. Slide the RIO Option Card into Slot #0. (See Fig. 5)