Cabling: installation, General introduction to cabling, Unpacking – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 25: Input power wiring, Fig. 20: power wiring diagram, Digital input wiring, Fig. 21: power supply board rear panel, Cabling, Y board rear panel, Rotary switches/se

11

Cabling

Installation

CABLING: INSTALLATION

General Introduction to Cabling

This section pertains to unpacking the instrument and instal-

lation of the Power, Load Cells, DeviceNet and Ethernet

Cables. For more detailed installation information please

refer to the HI 3000 Series Service Manual. For specification

information please read the HI 3000 Series Service Manual.

It is highly recommended that the user follow the installation

instructions either implied or explicitly stated in this section

to insure the instrument operates as designed.

Unpacking

Step 1. Before signing the packing slip, inspect the packing

for damage of any kind.

Step 2. Report any damage to the carrier company immedi-

ately.

Step 3. Check to see that everything in the package

matches the bill of lading.

Step 4. If any items are missing, damaged, or you have any

questions, please contact Technical Support at:

Hardy Process Solutions.

9440 Carroll park Drive

San Diego, CA 92121

Phone: (858) 278-4900

FAX: (858) 278-6700

Web Site: http://www.hardysolutions.com

E-Mail: [email protected]

Step 5. Record the model number and serial number of the

Filler/Dispenser Controller. Store in a convenient,

secure location for reference when contacting

Hardy Technical Support Department or to buy

parts or firmware upgrades.

Input Power Wiring

WARNING:

DO

NOT

OPERATE

WITH

INCORRECT

LINE

VOLTAGE

.

TO

DO

SO

WILL

RESULT

IN

PROPERTY

DAMAGE

AND

/

OR

PERSONAL

INJURY

. M

AKE

SURE

THAT

THE

POWER

SOURCE

DOES

NOT

EXCEED

240 VAC.

•

The AC power should be supplied by a “clean” primary

line, directly from the power panel. This line should not

supply any other equipment, including the feeding unit,

and should be supplied with a minimum 10 amp breaker.

(See Fig. 20)

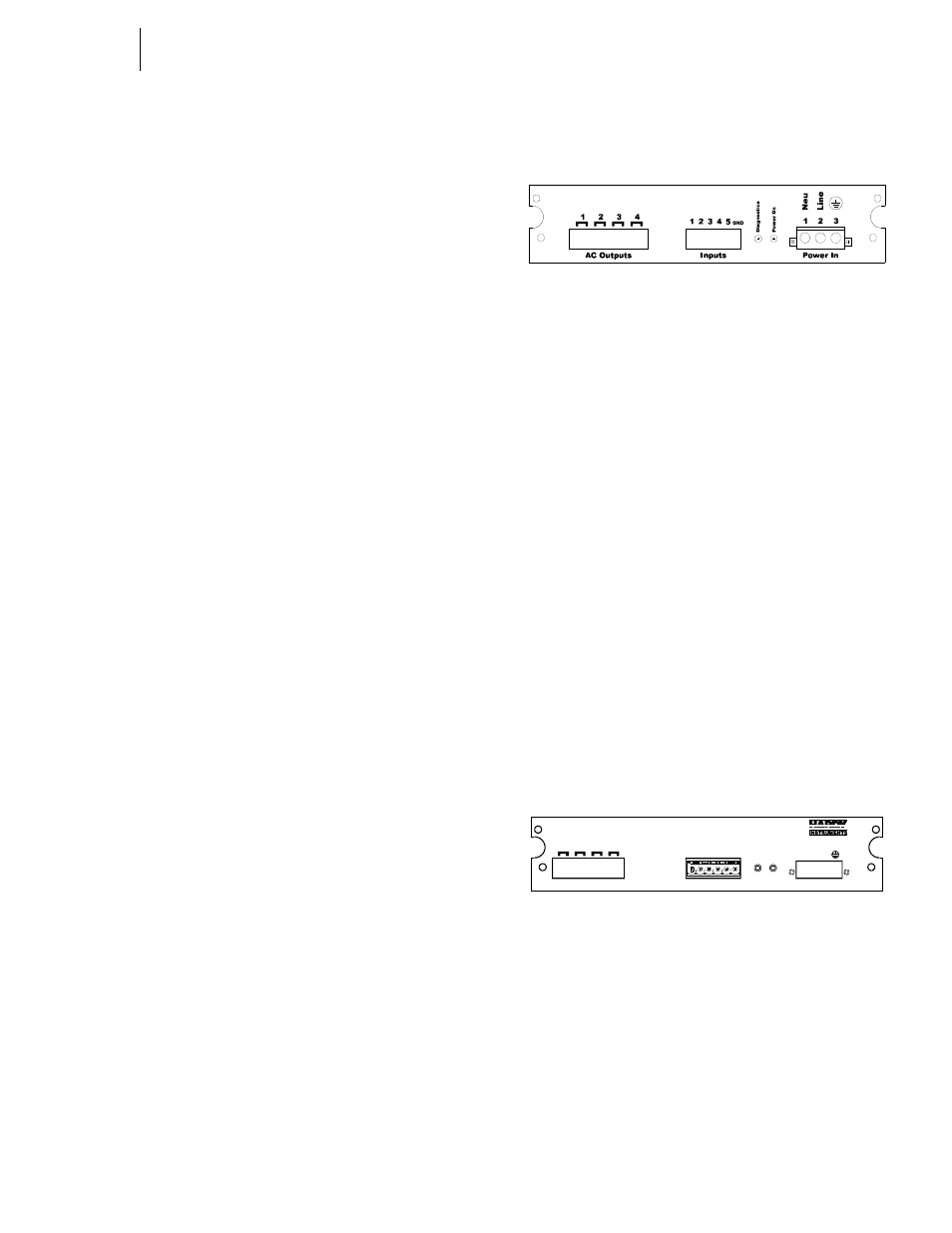

FIG. 20: POWER WIRING DIAGRAM

•

Power Input J1

J1-1 Neu (Low)

J1-2 Line (HI)

J1-3 Ground

Step 1. The HI 3000 Series instruments are configured with

a universal power supply rated from 120 to 240

VAC. The instruments can be powered by a 120 or

240 VAC power source and requires no switching

or jumper settings.

Step 2. Install a 3-wire, minimum 14 AWG power line to

the 3-pin terminal block connector. (See Fig. 20)

Step 3. The power and relay circuit card filters and condi-

tions AC power. However, for noisy power lines,

external conditioning may be required. For more

information, consult the HI 3000 Series Installation

and Service Manual or contact Hardy Instruments

Technical Support.

Digital Input Wiring

The 5 digital inputs to the HI 3000 series instruments are

mappable inputs and are only active when connected to

ground. (See Fig. 21)

FIG. 21: POWER SUPPLY BOARD REAR PANEL

WARNING: N

O

V

OLTAGE

EXCEPTED

AS

AN

INPUT

DRIVER

. D

O

NOT

WIRE

110 V

OLTS

INTO

THE

DIGITAL

INPUTS

. T

O

DO

SO

WILL

CAUSE

PROPERTY

DAMAGE

AND

/

OR

PERSONAL

INJURY

.

Step 1. Connect the input wire to the selected input.

Step 2. Connect the input wire to some form of dry contact

switch. (See Fig. 22)

Power In

Po

w

e

r O

n

D

iag

nos

ti

cs

Inputs

Gnd

1

2

3

4

5

Ne

u

Li

ne

www.hardyinst.com/3000

2

3

4

1

Outputs