2 introduction: parameterising the controller, Introduction: parameterising the controller, 2introduction: parameterising the controller – Lenze 8400 BaseLine C User Manual

Page 12

2

Introduction: Parameterising the controller

12

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2

Introduction: Parameterising the controller

[2-1]

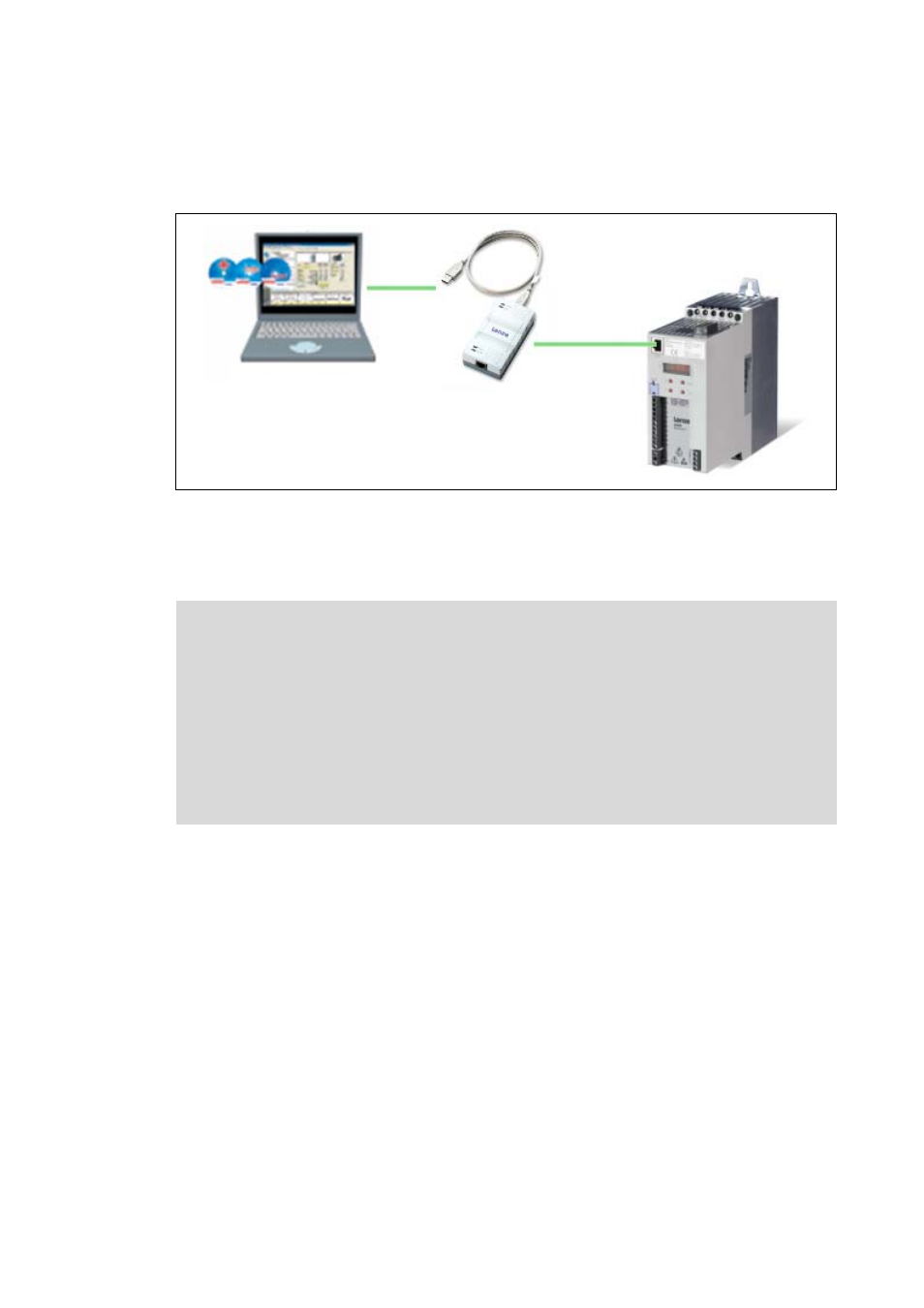

Example configuration for parameterising the controller (here: BaseLine D)

Being a component of a machine which includes a speed-variable drive system, the controller needs

to be adjusted to its drive task and the motor. The controller is adjusted by changing parameters

which are saved in the memory module.

The parameters can optionally be accessed from the integrated keypad, or the L-force »Engineer«,

or a master control via fieldbus communication:

• The USB diagnostic adapter, for instance, can be used for the communication between the PC

(including the L-force »Engineer« software) and the controller, see illustration. The USB diag-

nostic adapter is the connection between the PC (free USB port) and the controller (diagnostic

interface).

• For fieldbus communication, the 8400 BaseLine C controller is provided with a CANopen inter-

face.

Danger!

In general, changing a parameter causes an immediate response in the controller!

• This may lead to undesirable behaviour on the motor shaft if the controller has been

enabled!

• Setpoint sources, for instance, may switch over all of a sudden (e.g. when configuring

the signal source for the main setpoint).

Certain device commands or settings which may cause critical states of drive behaviour

constitute exceptions. Such parameter changes are only possible if the controller is inhi-

bited. Otherwise, a corresponding error message will be issued.