8 shifting a cnc program, 9 rotating the cnc program, 10 stretch the cnc program – Lenze PLC Designer PLC-Designer (R2-x) SoftMotion User Manual

Page 74: 11 invert direction, Shifting a cnc program, Rotating the cnc program, Stretch the cnc program, Invert direction, L-force | plc designer - softmotion

L-force | PLC Designer - SoftMotion

CNC editor

Starting the CNC editor, inserting and managing CNC programs

74

L

DMS 5.2 EN 03/2011 TD17

4.2.7

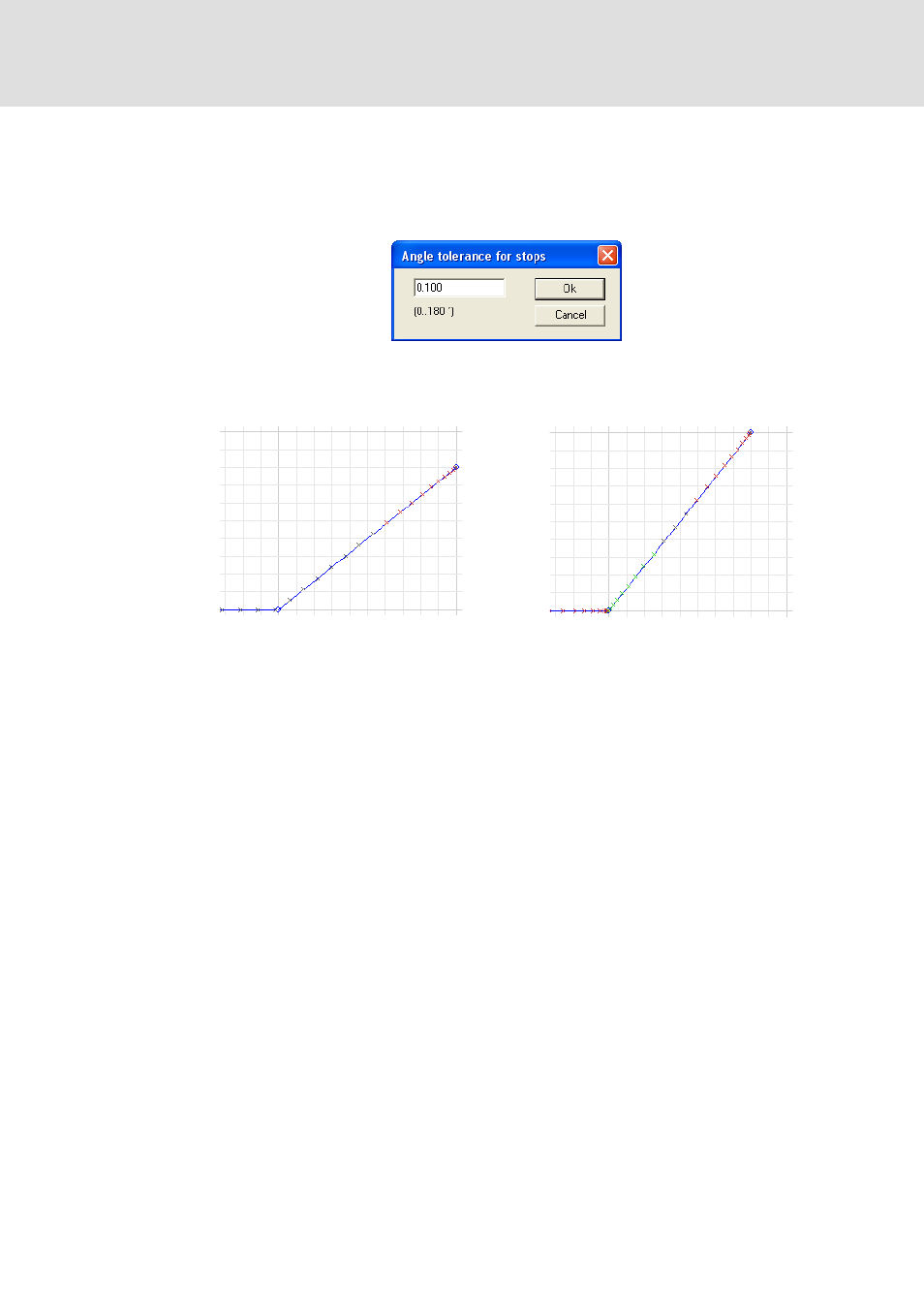

Defining the angular tolerance for stopping in the CNC program

In the Angle tolerance for stops dialog you can set the path bend sensitivity. The value

entered defines the limit angle for the tangents of two path objects in excess of which a

stop will be induced.

Angular tolerance 45°

4.2.8

Shifting a CNC program

Select this menu item and enter a displacement vector in the Translation vector dialog. The

current CNC program will be moved by this vector.

Values can be entered for the following axes: X, Y, Z, P, Q, U, V, W.

4.2.9

Rotating the CNC program

To rotate the current program, select this menu item and enter the rotation angle in the

Rotation angle dialog. The CNC program will be rotated counter-clockwise around the zero

point by the specified angle.

4.2.10

Stretch the CNC program

Enter the stretch factor in the Stretch factor dialog. The CNC program will be stretched by

the specified factor.

4.2.11

Invert Direction

Select this menu item to invert the path and induce processing in the opposite direction.

The positions of switch markers do not change.