1 parameterising analog modules, 1 parameter data, Parameterising analog modules – Lenze EPM−T9XX Modular system User Manual

Page 413: Parameter data, 13 parameter setting via profibus−dp, Parameterising analog modules parameter data, Stop

Parameterising analog modules

Parameter data

Parameter setting via PROFIBUS−DP

13.1

13.1.1

L

13.1−1

EDSPM−TXXX−9.0−11/2009

13.1

Parameterising analog modules

13.1.1

Parameter data

(

Stop!

The modules are not protected against wrong parameter settings

by the hardware. They will be destroyed if the signals or encoders

connected do not match the measuring range set:

l

Max. 15 V input voltage in the voltage measuring range.

l

No input voltage in the resistance measuring range.

l

When the measuring range is changed, only assign the inputs

after the first gateway initialisation has been completed:

– During initialisation, the previous settings are still active.

Unsuitable input circuits may destroy the modules. Changes

will only become effective and are permanently saved after

initialisation.

l

For a 4×analog input module, 10 bytes of parameter data are available. The

following are defined via the parameter data

– The signal function for each input (current measurement, voltage

measurement, temperature measurement etc.),

– The module error behavior,

– The conversion speed.

l

The module can be parameterised with the configuration tool or via slot and

index.

– To set the parameters via slot and index, the function blocks SFB 52 (read)

and SFB 53 (write) are required.

(

¶ 10.5−3)

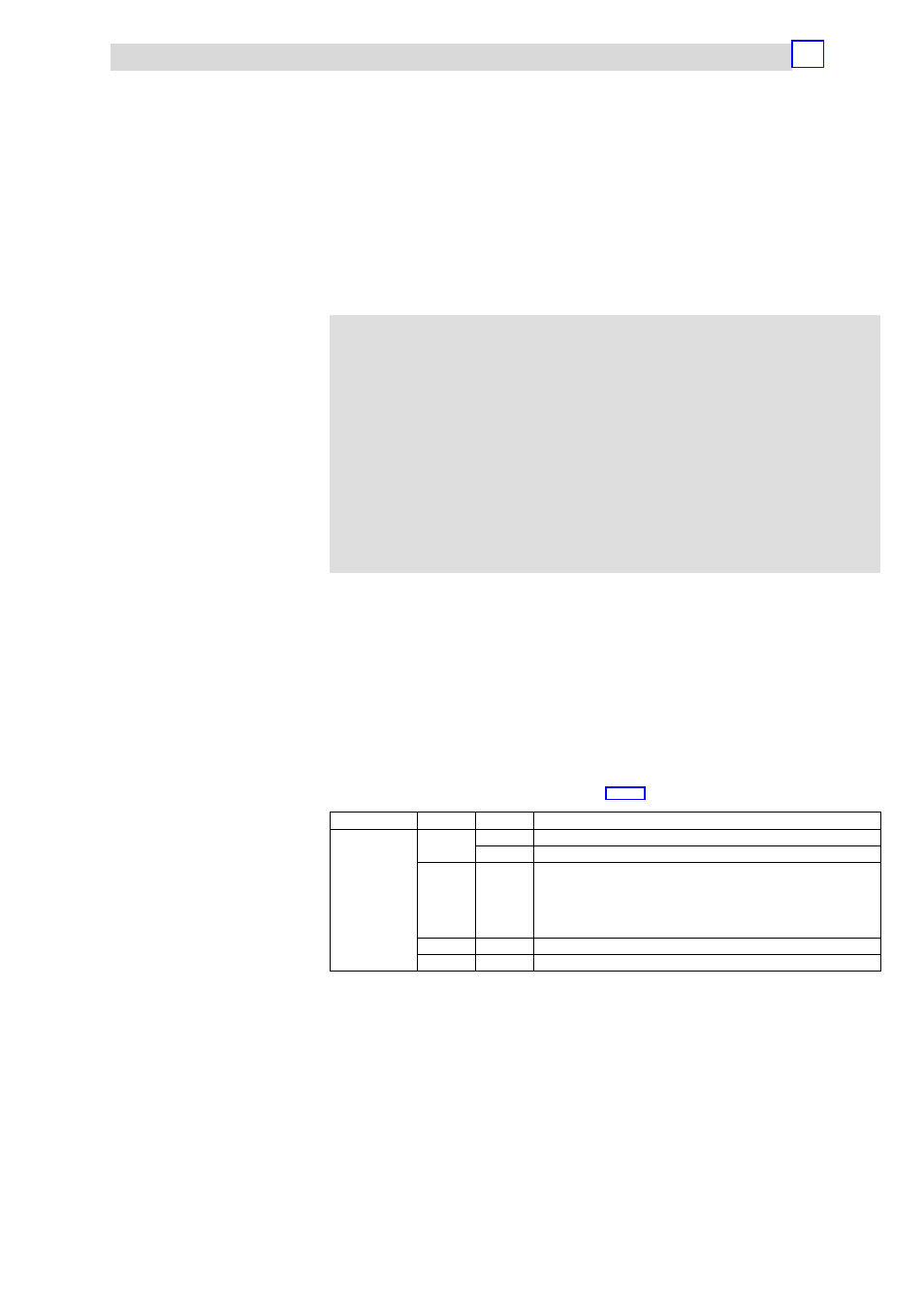

Slot number

Index

Access

Description

1 ... 32

00

h

R

Read out diagnostic data record 0

W

Write parameters to the module

01

h

R

The corresponding diagnostic data record of the electronic module can be

read out via the index.

·

Example:

– Index 01

h

: read out diagnostic data record 1

– Index 02

h

: read out diagnostic data record 2

F1

h

R

Read out the module parameters

F2

h

R

Read out the process image of the module

R = read

W = write

4xanalog input module