NORD Drivesystems BU0300 User Manual

Page 87

7.8 Control terminals

BU 0300 EN

Subject to technical alterations

87

Parameter

Setting value / Description / Note

Supervisor

Parameter

set

Available with option

P401

Analog input mode 1

S

BSC

STD

0 ... 3

[ 0 ]

0 = 0 – 10V limited:

An analog setpoint smaller than the programmed adjustment 0% (P402) does not lead to

undershooting of the programmed minimum frequency (P104). Therefore does not lead to

any rotation direction reversal.

1 = 0 - 10V:

If a setpoint smaller than the programmed adjustment 0% (P402) is present, this can

cause a change in direction rotation. This allows rotation direction reversal using a simple

voltage source and potentiometer.

E.g. internal setpoint with rotation direction change: P402 = 5V, P104 = 0Hz,

Potentiometer 0–10V

⇒ Rotation direction change at 5V in mid-range setting of the

potentiometer.

During the reversing moment (hysteresis =

± P505), the drive stands still when the

minimum frequency (P104) is smaller than the absolute minimum frequency (P505). A

brake that is controlled by the FI will be closed in the hysteresis range.

If the minimum frequency (P104) is greater than the absolute minimum frequency (P505),

the drive reverses when the minimum frequency is reached. In the hysteresis range

±

P104, the FI supplies the minimum frequency (P104), the brake controlled by the FI does

not close.

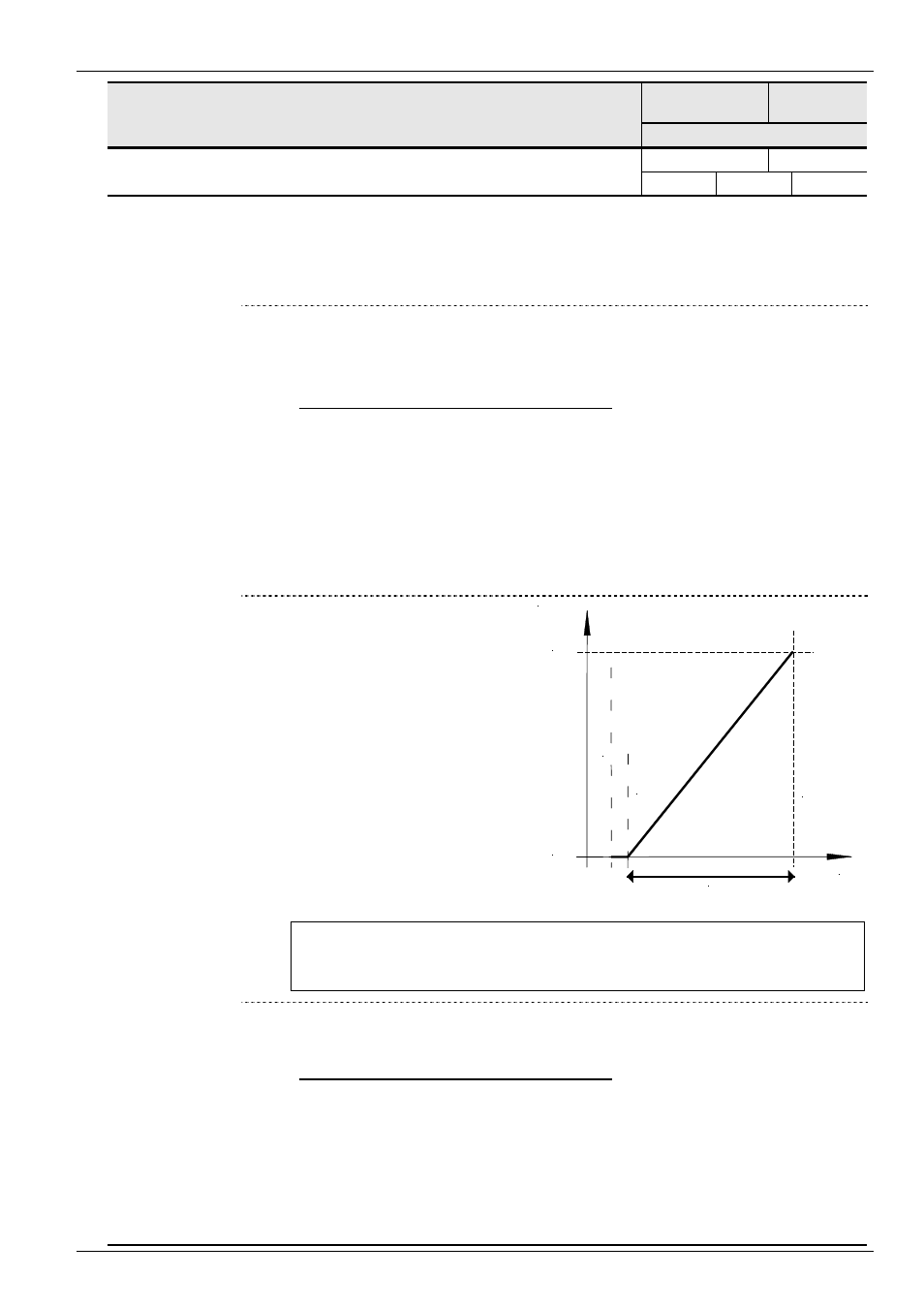

2 = 0 – 10V monitored:

If the minimum adjusted setpoint

(P402) is undershot by 10% of the

difference value from P403 and

P402, the FI output switches off.

Once the setpoint is greater than

[P402 * (10%*(P403-P402))], it

will deliver an output signal again.

f / Hz

P104

(fmin)

P105

(fmax)

P40

3 =

10

,0

V

P

402 = 2

.0V

= 8.0V

U/V

O

F

F

= 2.

0V

-

10%

*

8.

0V

= 1

.2V

E.g. setpoint 4-20 mA:

P402: Adjustment 0% = 1V; P403: Adjustment 100% = 5V; -10% corresponds to -0.4V;

i.e. 1...5V (4...20mA) normal operating zone, 0.6...1V = minimum frequency setpoint,

below 0.6V (2.4mA) output switches off.

3 = -10 - 10V: If a setpoint smaller than the programmed adjustment 0% (P402) is present, this

can cause a change in direction rotation. This allows rotation direction reversal using a

simple voltage source and potentiometer.

E.g. internal setpoint with rotation direction change: P402 = 5V, P104 = 0Hz,

Potentiometer 0–10V

⇒ Rotation direction change at 5V in mid-range setting of the

potentiometer.

During the reversing moment (hysteresis =

± P505), the drive stands still when the

minimum frequency (P104) is smaller than the absolute minimum frequency (P505). A

brake that is controlled by the FI will not be closed.

If the minimum frequency (P104) is greater than the absolute minimum frequency (P505),

the drive reverses when the minimum frequency is reached. In the hysteresis range

±

P104, the FI supplies the minimum frequency (P104), the brake controlled by the FI does

not close.