NORD Drivesystems BU0300 User Manual

Page 19

2 Assembly and installation

BU 0300 EN

Subject to technical alterations

19

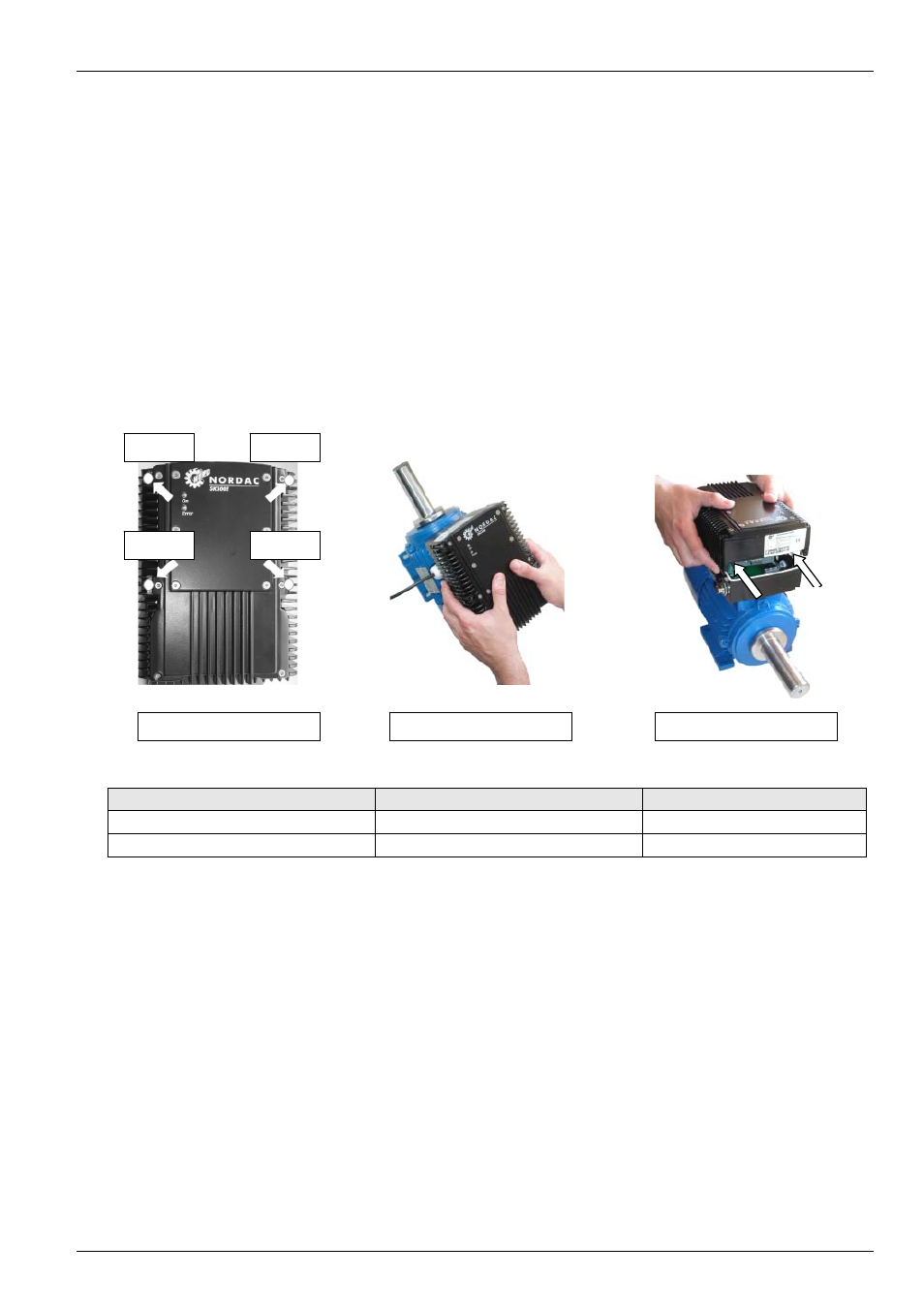

2.3.6 Mounting the SK 300E frequency inverter

The frequency inverter must first be removed before it can be electrically connected. To do this, undo the 4

fastening screws (Fig. 1) so that the frequency inverter can be lifted off vertically (Fig. 2). After connecting the

supply voltage, the frequency inverter must be vertically reattached (Fig. 3), beginning with the plugs on the

rating plate side which ensure that the inverter is positioned correctly. Further information about attaching

customer units can be found in Chap. 3.3.3 “Mounting the customer unit”

In order to achieve the maximum protection class IP55 / IP66, it must be ensured that all fastening screws of

the frequency inverter are tightened in the specified sequence from screw 1 to screw 4 and with the torque

specified in the table below. Use appropriate screwed connections for the connection line cable cross-section.

Dissipation of heat generated by the inverter occurs via convection . The driven motor must have normal

ventilation. Heat dissipation must not be hindered by significant contamination.

A cover plate with 2 LEDs is normally located on the top side of the frequency inverter. These LEDs show the

status of the frequency inverter. Note that the green LED constantly lights when the mains voltage is applied,

and the red LED according to the error message, e.g. 5 flashes - pause - 5 flashes, etc. for the error E005.

Fig.1: Fastening screws

Fig.2: Removing the SK 300E

Cinch connector

Fig.3: Attaching the SK 300E

Screw 2

Screw 1

Screw 4

Screw 3

Frequency inverter size

Screw size

Tightening torque

S 1

M5 x 35

3.5Nm ± 20%

S 2

M5 x 50

3.5Nm ± 20%