Additional parameters, P503 leading function output, P504 pulse frequency – NORD Drivesystems BU0300 User Manual

Page 102: P505 absolute minimum frequency

NORDAC trio SK 300E Manual

102

Subject to technical alterations

BU 0300 EN

7.9

Additional parameters

Parameter

Setting value / Description / Note

Supervisor

Parameter

set

Available with option

P503

Leading function output

S

Always available

0 ... 4

[ 0 ]

To use the master function output, the inverter controller source must be selected in P509. Only the

master frequency (setpoint 1) is transferred with Mode 1, while the actual values selected in P543,

P544 and P545 are transferred in Mode 2.

When using the USS mode:

If the SK 300E is operated with a connected ParameterBox, the external USS channel for bus control

is blocked. The external USS communication is automatically initiated when the ParameterBox

connection is interrupted. If the FI has to be re-parameterised, the bus communication will be

interrupted when the ParameterBox is connected.

0 = Off

1 = USS mode 1

2 = CAN mode 1

3 = USS mode 2

4 = CAN mode 2

P504 Pulse

frequency

S

Always available

3.0 ... 10.0 kHz

[ 6.0 ]

The internal pulse frequency for actuating the power component can be changed with this parameter.

A higher setting reduces motor noise, but leads to increased EMC emissions and reduction of the

possible motor nominal torque.

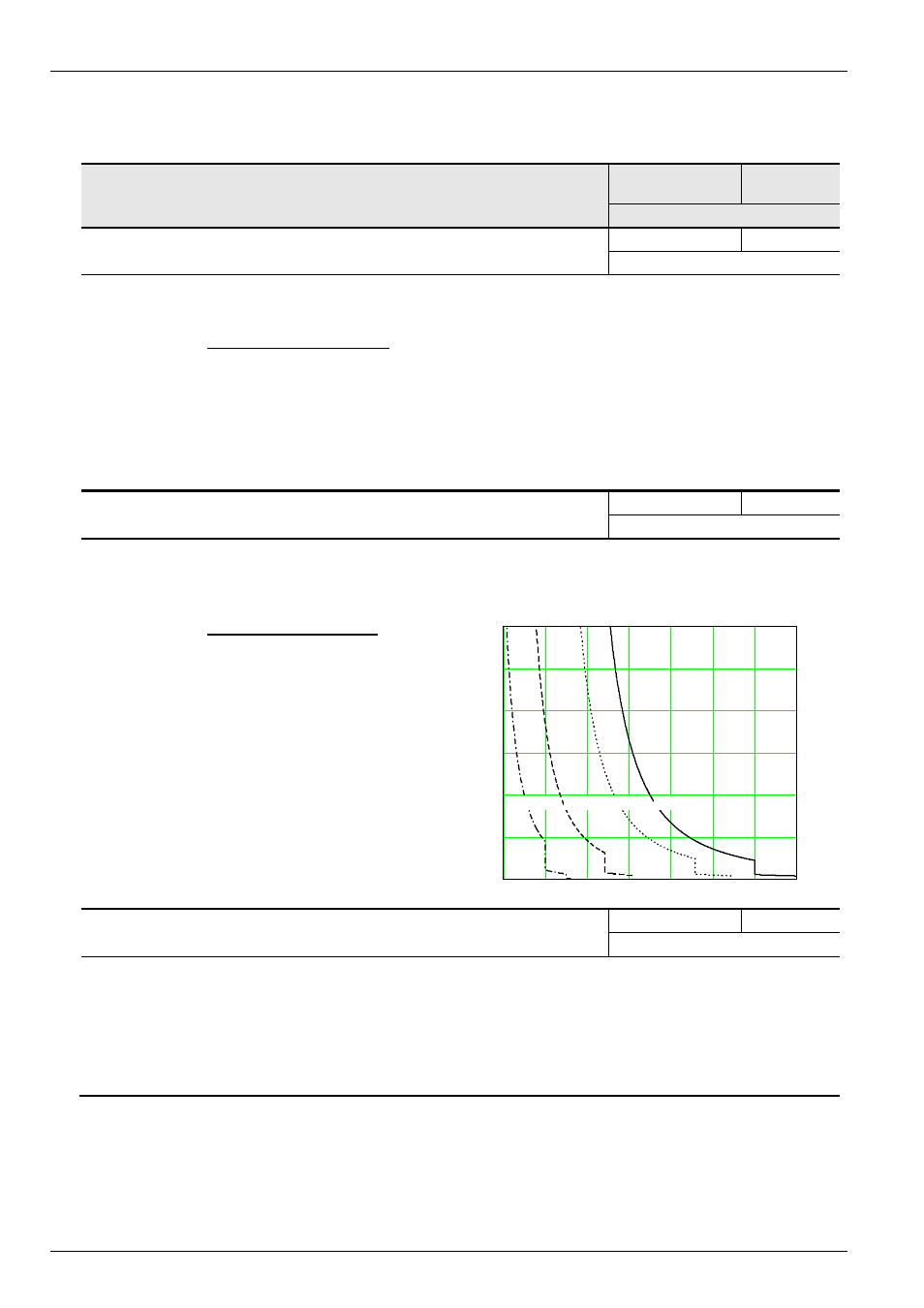

I

2

t- characteristic curve FI

, raising

the pulse frequency leads to a

reduction of the output current

dependent on time.

Note

Æ

The noise suppression grade

limit curve B (for FI attached to motor)

is reached with the setting 6kHz

t sec

(

)

0.8

1

1.2

1.4

1.6

1.8

2

2.2

0

30

60

90

120

150

180

20 kHz 16 kHz

10 kHz <=6kHz

x Inenn

.

P505

Absolute minimum frequency

S P

Always available

0.1 ... 10.0 Hz

[ 2.0 ]

Gives the frequency value that cannot be undershot by the FI. If the setpoint becomes smaller than

the absolute minimum frequency, the FI switches off or changes to 0.0Hz.

At the absolute minimum frequency, braking control (P434 or P441) and the setpoint delay (P107)

are actuated. If a setting value of "Zero" is selected, the brake relay does not switch during reversing.

When controlling lift equipment, this value should be set at a minimum of 2Hz. From 2Hz, the current

control of the FI operates and a connected motor can supply sufficient torque.

NOTE:

Output frequencies < 2Hz lead to current limitation.