NORD Drivesystems BU0300 User Manual

Page 25

2 Assembly and installation

BU 0300 EN

Subject to technical alterations

25

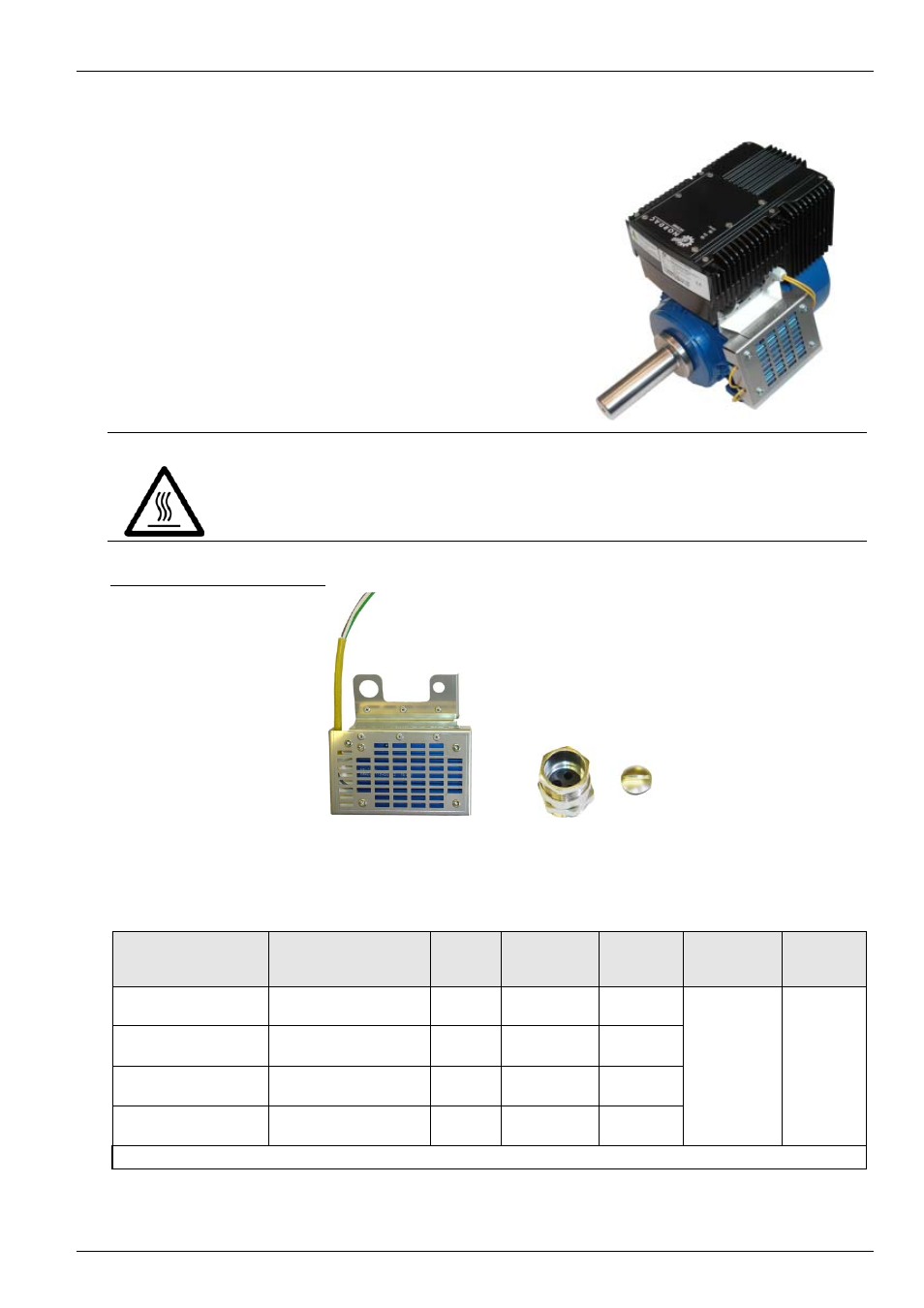

2.7

Brake resistor

During dynamic braking (frequency reduction) of a three-phase

motor, electrical energy is returned to the inverter. In order to

avoid overcurrent switch-off of the frequency inverter, the

integrated brake chopper can convert the returned energy into

heat by connecting an external braking resistor.

2 screw connections, which should be fitted with the appropriate

seals, are enclosed for mounting the braking resistor on the

frequency inverter (M20 for the cable and M12 for the holder).

Suitable installation material is provided to mount the brake

resistor on the adapter unit TI 0/2.

CAUTION

The braking resistance and all other metal components can heat up to temperatures above 70°C.

When mounting, sufficient distance from neighbouring components must be maintained. When working

on the components, allow sufficient cooling time beforehand

Contents of the module (TI 0/1)

Screw connections,

for fastening the

braking resistor

Braking resistor

Frequency inverter

type

Resistor type

Resis-

tance

Continuous

rating

*) Pulse

output

(approx.)

Connection

leads,

400mm

Protection

type

SK 300E-550-340-B …

SK 300E-151-340-B

SK BR3-120/100-TI 0/1

Part. No. 275140010

120

Ω

100 W

1.0 kW

FEP AWG

14/19 wh,gy;

PTFE AWG

12/19 gn

IP67

SK 300E-221-340-B …

SK 300E-401-340-B

SK BR3-82/200-TI 0/1

Part. No. 275140020

82

Ω

200 W

2.0 kW

SK 300E-550-340-B …

SK 300E-151-340-B

SK BR3-120/100-TI 0/2

Part. No. 275140030

120

Ω

100 W

1.0 kW

SK 300E-221-340-B …

SK 300E-401-340-B

SK BR3-82/200-TI 0/2

Part. No. 275140040

82

Ω

200 W

2.0 kW

*) permitted, depending on application, max. 5% ED / 120s (700VDC)