Nordac, Frequency inverter, Fi/hz – NORD Drivesystems BU0300 User Manual

Page 73

6 Commissioning

BU 0300 EN

Subject to technical alterations

73

6.2

Different motor

Using a different motor to delivery condition:

Note

In order to make the motor parameters visible, first set parameter P003 "Supervisor Mode" to 1

(see also parameter P003 Æ, Page 78)!!!

A motor list for standard motors is stored in the device. Select the standard motor in parameter P200 "Motor list".

The relevant data is loaded automatically in parameters P201 – P208 and must be compared again with the

data on the motor rating plate.

When using other motors, the data from the rating plate of the motor must be input into parameters P201 to

P208.

To determine the stator resistance automatically, parameter P208 must be set to "0" and confirmed with

the ENTER key. A single automatic measurement of the stator resistance now takes place. The value

adjusted to the line resistance will be stored. This is dependent on the motor circuit entered in parameter

P207 (star/delta circuit).

6.3

Initial check with the ParameterBox

Check first of all whether all cables are connected correctly and whether all relevant safety precautions have

been taken.

Only then can the mains voltage be applied to the frequency inverter. When the ParameterBox is connected,

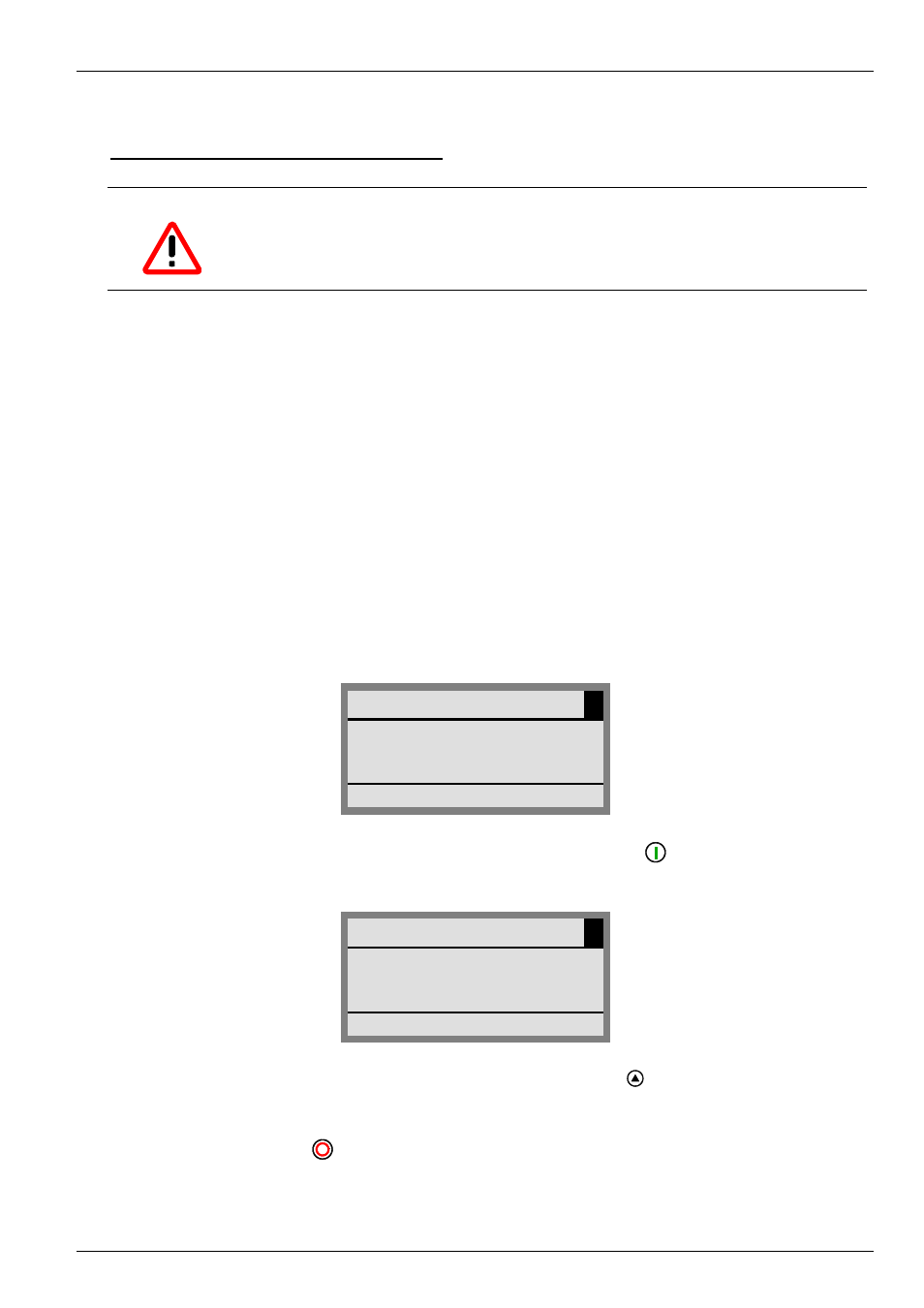

the following window appears in the ParameterBox display:

300E 1.5kW/3 BSC

1

> NORDAC <

Frequency inverter

ONLINE

I1

P1

EReady

Ensure that the motor can start-up without danger. Press the START

key on the ParameterBox.

The display changes to:

300E 1.5kW/3 BSC

1

Fi/Hz

U/V

I/O

0.0

27

1.2

ONLINE

I1

P1

R RUNNING

Check that the motor is running in the direction required by pressing the - key, thereby increasing the set

frequency.

The actual output frequency, voltage and current are displayed.

After pressing the STOP key

, the motor stops according to the set braking time. After this time has expired,

the display will revert to the previous one.

The following parameters can now be changed if necessary.