9 technical data 9.1 – NORD Drivesystems BU0300 User Manual

Page 124

NORDAC trio SK 300E Manual

124

Subject to technical alterations

BU 0300 EN

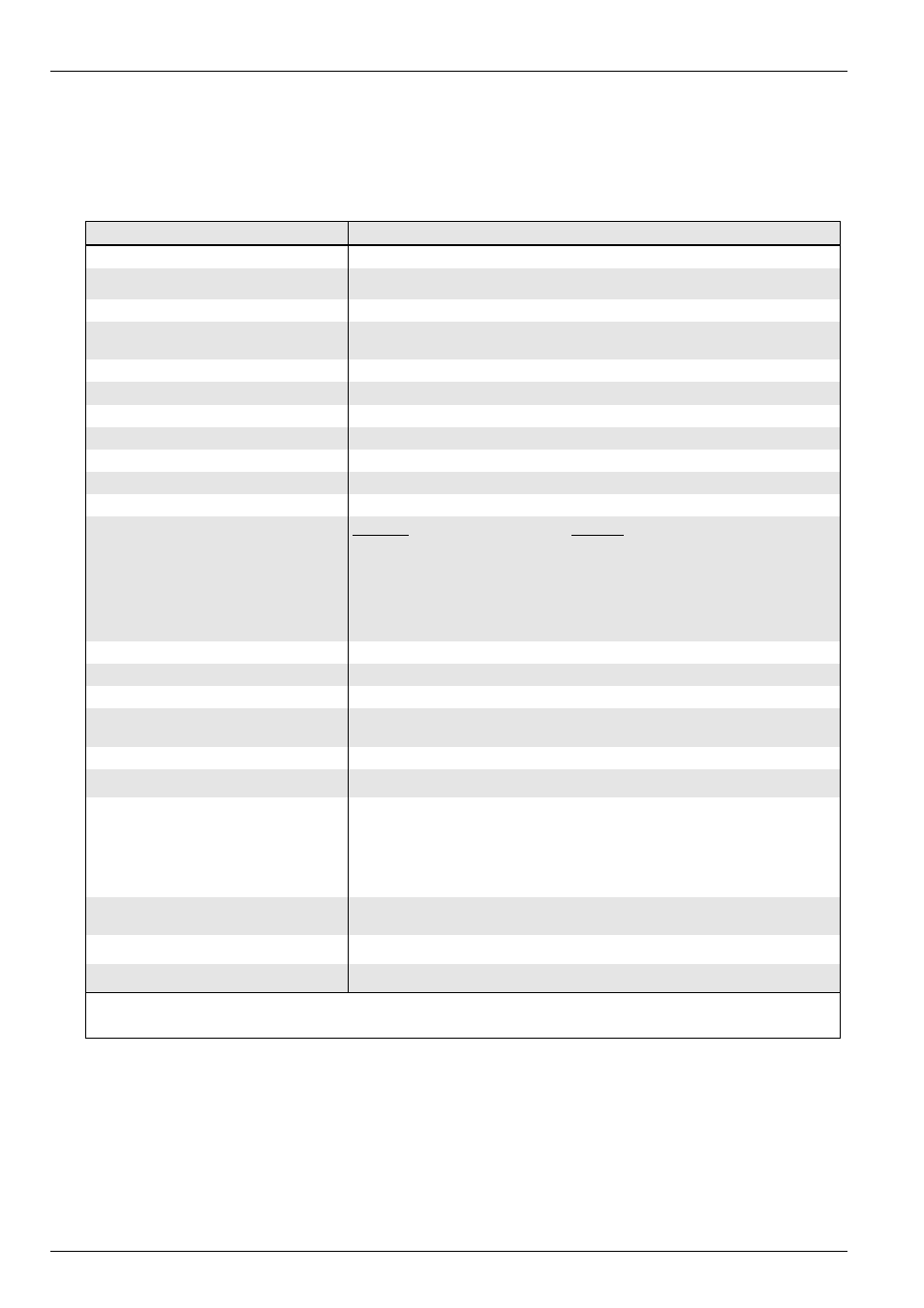

9 Technical data

9.1

General Data

Function

Specification

Output frequency

0.0 ... 400.0 Hz

Pulse frequency

3.0

… 10.0kHz, standard setting = 6kHz

Rated overload capacity

150% for 30 s, peak value 200% for 3 s

Protective measures against

Overtemperature of the frequency inverter

Short-circuit, earth fault,

over/under-voltage

overload, idle running

Regulation and control

Sensorless current vector control (ISD), linear V/f characteristic

Analog setpoint input / PI input *

0 … 10 V (Ra

≈ 28kΩ) or 0 / 4 … 20 mA (Ra ≈ 250Ω)

Analog setpoint resolution *

10 bit based on measurement range

Setpoint constancy

Analog < 1%

Digital < 0.02%

Analog output *

0…10V, max. 5mA scalable, digital functions possible

Motor temperature monitoring

I

2

t motor (UL/cUL certified), PTC / Bimetal switch (not UL/cUL)

Control outputs

1 relay 24V DC max. 500mA load

Interface *

Standard:

RS485

Optional:

Profibus DP

CAN Bus

CANopen

DeviceNet

InterBus

AS-Interface

Efficiency of frequency inverter

Approx. 95 %

Ambient temperature

-10°C ... +50°C (without condensation)

Storage/Transport temperature

-20°C ... +60°C / +70°C, (max. 85% without condensation)

Long-term storage

Connect the frequency inverter to the mains voltage for 60 minutes at least

once a year. Maintain this cycle throughout the storage period.

Protection type

IP55 / IP66 (option), dependent on motor used

Galvanic isolation

Control terminals (digital inputs / outputs)

Max. mounting height above zero

Up to 1000m: No power reduction

1000...4000m: 1%/ 100m power reduction

(up to 2000m overvoltage category 3)

2000...4000m: Only overvoltage category 2 is maintained, external

overvoltage protection at the mains input is necessary

Wait time between two mains switch on

cycles

60 sec for all devices in normal operating cycle

Supply voltage 15V/5V

see page 22

Certifications

CE, UL, cUL

*) optional, with SK CU2-BSC or –STD, BUS units SK TU2-…