Xl™ series – Xylem XL Series H-522 - Plus User Manual

Page 229

XL™ Series

Operation with the H-355 "Smart Gas" System 21-3

PC Interface View Built In Display Screen

Line Pressure: XX.XX PSI

Line PSI = XX.X

This is the current pressure the H-355 sees on the orifice line. This pressure should always be

less than the tank pressure. The difference between this pressure and the tank pressure is what

determines the bubble rate. The difference should be about 3 to 5 PSI. As the water level rises

the line pressure will increase, approaching the tank pressure. The H-355 detects this rise in

pressure and will turn on the compressor in order to rise the tank pressure, therefore maintaining

the desired bubble rate.

PC Interface View Built In Display Screen

Bubble Rate

Bubble Rate [XXX]/Min

This refers to the average number of bubbles per minute that are flowing from the end of the

orifice tube. The programmable range is 30 to 120 bubbles per minute using a standard 1/8 inch

ID orifice line.

One reason for changing the bubble rate is to set how quick the system will respond to a rise in

stage. The following table shows the approximate time needed to react to a one foot rise in stage

for the different bubble rates. Note this is at a depth of one foot. At greater depths the time will

increase slightly.

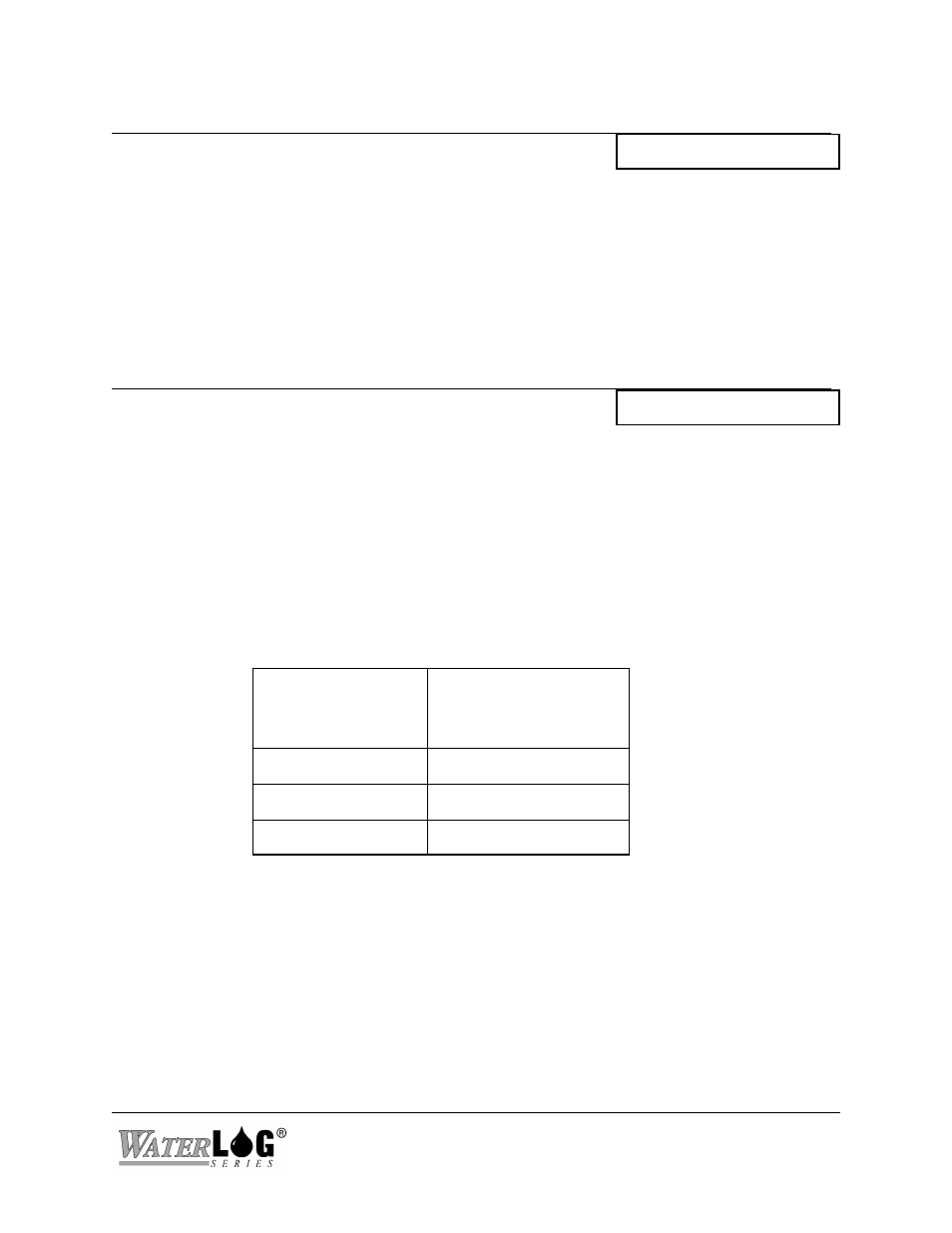

Bubble Rate

(Bubbles Per

Minute)

Response Time For

1.0 Foot Stage Rise

(at a depth of one foot)

30 Bubbles / Min

25 Seconds

60 Bubbles / Min

20 Seconds

120 Bubbles / Min

15 Seconds

Another reason for changing the bubble rate may be to reduce noise in the data. Some sites have

turbulent water conditions creating water level data that looks jittery. The bubble rate may be

changed, up or down, to find an optimal point to reduce this noise. Normally it is a combination

of changing the bubble rate and the averaging time to produce the best results. The default

values work best in the majority of the applications providing desirable results in a timely manor.