Gateway communications manual – AERCO XPC GATEWAY Communications User Manual

Page 52

GATEWAY COMMUNICATIONS MANUAL

52

Although it is recommended to utilize the AERCO BMS for boiler system control, a customer may opt to

utilize their own boiler system control system. If such is the case, the BMS/BMS II may be removed

entirely allowing the customer’s BAS/EMS system to interact directly (possibly using a protocol

translating XPC Communications Gateway device, if needed) with the C-More boiler controller. If the

BMS/BMS II is kept in the loop and Modbus Pass Thru is enabled, those control functions normally set by

the BMS/BMS II will continue to do so. All other control functions will now be facilitated by BAS/EMS

commands passed thru the BMS/BMS II directly to the C-More boiler controller.

If the BAS being utilized supports Modbus RTU protocol, it can be connected to the BMS either directly or

via a RS485-to-RS232 converter. However, if the BAS does not support Modbus protocol and utilizes

BACnet, N2 or LonWorks, the AERCO XPC Gateway must be used as described below.

1. Make the connections between the BMS and XPC Gateway as instructed in subsections 3.2.1.1 or

3.2.1.2.

2. Set up the C-More Boiler Controllers as described in Section 2, subsections 2.3 through 2.5.1.

3. Connect the C-More Boiler Controllers in a “Daisy-Chain” configuration.

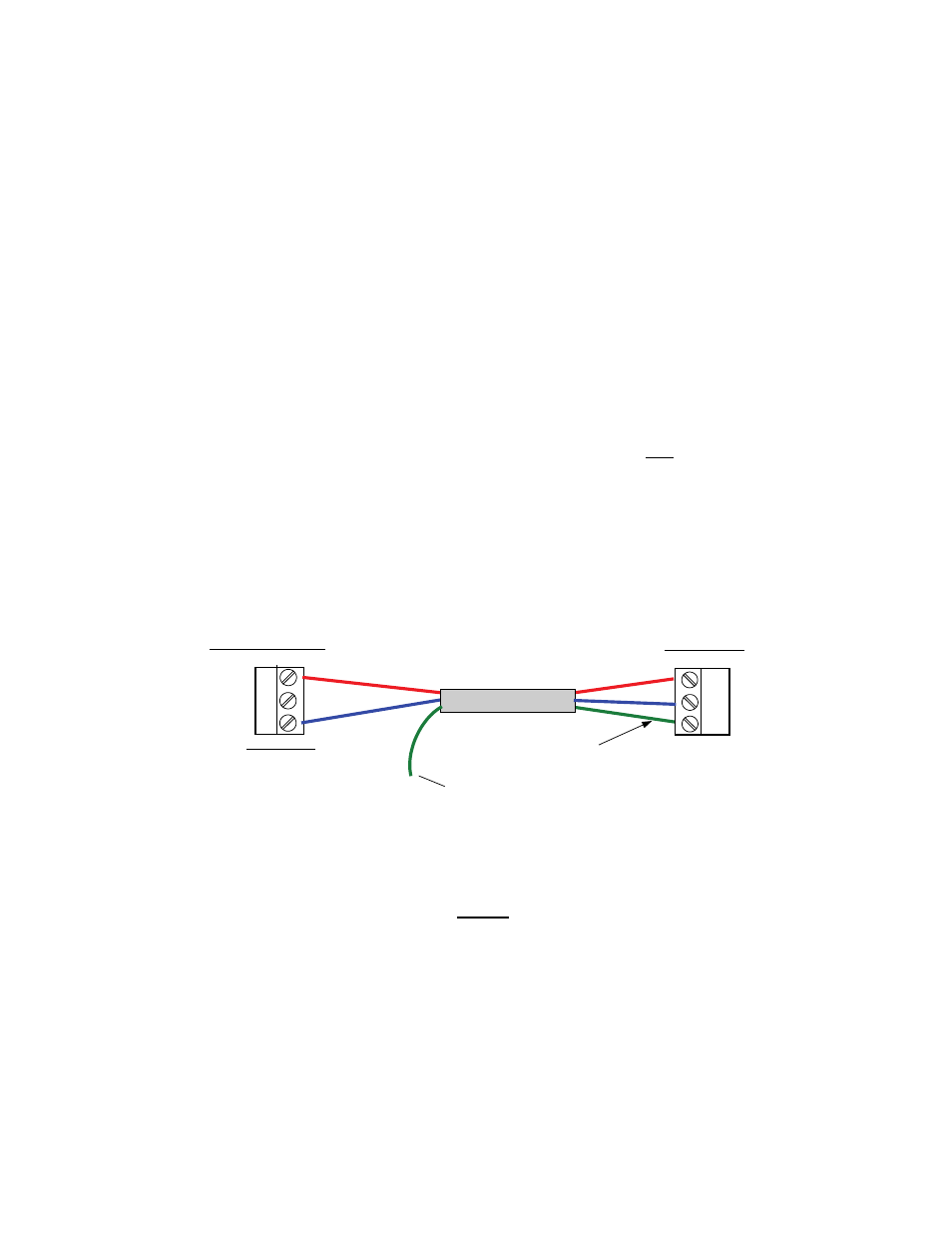

4. Refer to Figure 3-7 and connect the RS485 COMM terminals of the first C-More Boiler to the BMS

internal RS485 connector JP11 as follows:

(a)

(a) Connect the RS485 COMM + terminal to the +(B) terminal of JP11 in BMS.

(b) Connect the RS485 COMM - terminal to the -(A) terminal of JP11 in BMS.

(c) Terminate the shield at the BMS end only.

+

G

-

TERMINATE SHIELD

AT BMS ONLY

+ (B)

- (A)

SHLD

C-MORE I/O BOX

R

S

48

5 C

O

M

M

BMS RS485

JP11

FIRST UNIT

S

H

IE

L

D

TIE TOGETHER WITH

SHIELDS OF OTHER

C-MORE UNITS

RED (+)

BLUE

(-)

RED

(+)

BLUE (-)

Figure 3-7. BMS Connections to C-More Controller

NOTE

Refer to AERCO Instruction Manual GF-108M for additional information on

BMS keypad functions and displays.

5. With the BMS in the Field Adjust Mode, continue pressing the AIR TEMP key until MODBUS PASS

THRU

is displayed. Press the ▲ or ▼ arrow key until the second line of the display shows

ENABLED.

6. With PASS THRU set to ENABLED, both the BMS and the boilers can now be monitored.