Installation – Lenze 8200 Frequency inverters User Manual

Page 88

Installation

8200SHB0199

4-31

Types 824X

U V W

PE

U V W

T1 T2

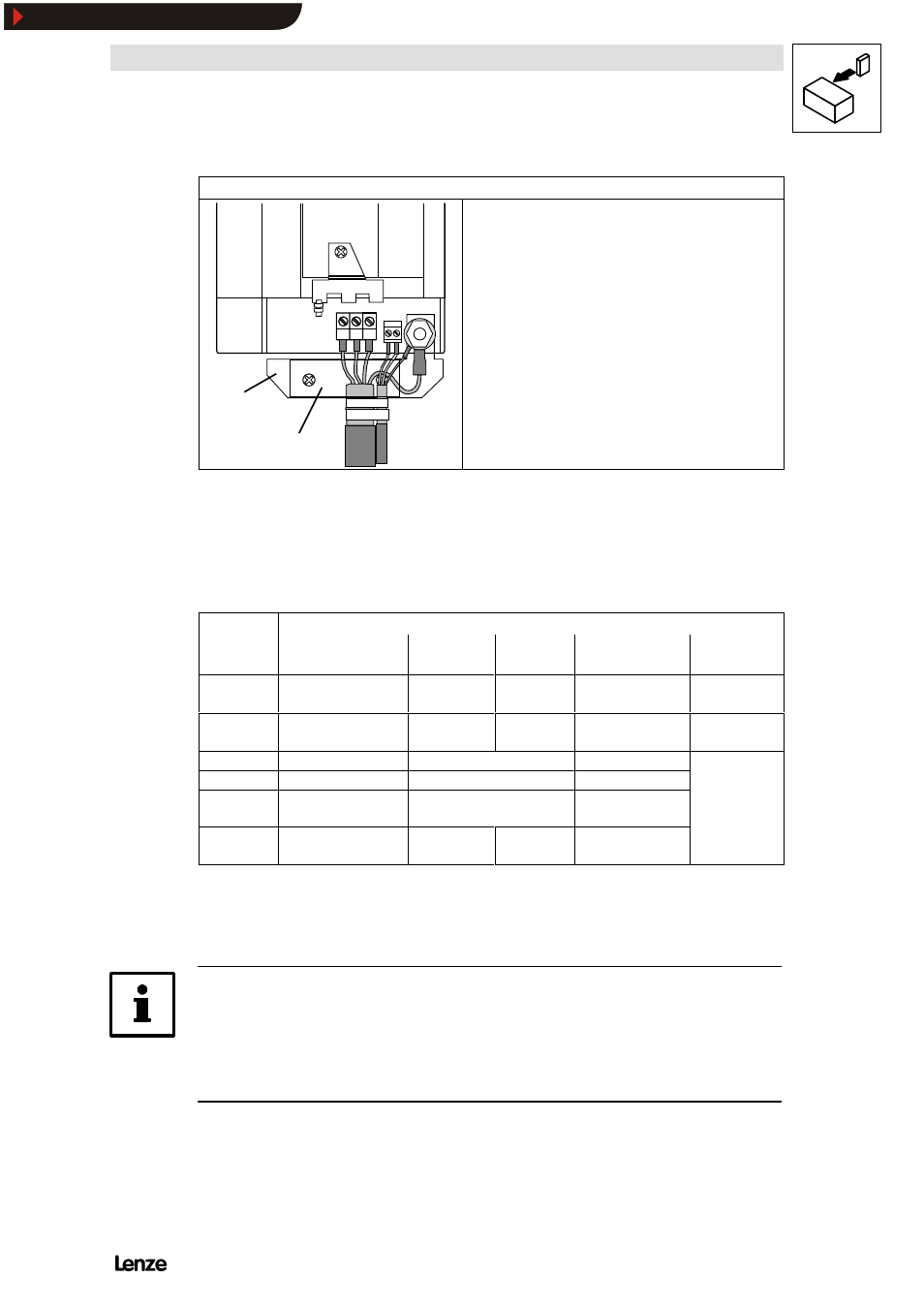

Correct screen connection with screened cables

(required parts in the accessory kit):

-

Screw sreen plate

➀

on fixing bracket

➁

.

-

Fix the screen of the motor cable and thermal contact. Do

not use as a strain relief!

-

To improve the screen connection: Connect the screen

additionally to the stud PE next to the motor connections.

FIG 4-18

Proposal for motor connection with 824X

-

Connect the motor cables to the screw terminals U, V, W.

- Observe correct pole connection.

- Max. permissible cable cross-sections and tightening torques

Terminals

Type

Max. permissible

cable cross-sections

U, V, W

PE

connection

Screen/

strain relief

T1, T2

8201 - 8214

2.5 mm

2

0.5 ... 0.6 Nm

(4.4 ... 5.3 lbin)

1.7 Nm

(15 lbin)

-

-

8215 - 8218

4 mm

2 1)

0.5 ... 0.6 Nm

(4.4 ... 5.3 lbin)

1.7 Nm

(15 lbin)

-

-

8221 - 8223

25 mm

2 2)

4 Nm (35 lbin)

-

8224 - 8225

95 mm

2 2)

7 Nm (62 lbin)

3.4 Nm (30 lbin)

8226 - 8227

120 mm

2 2)

12 Nm (106.2 lbin)

M4: 1.7 Nm (15 lbin)

M5: 3.4 Nm (30 lbin)

0.5 ... 0.6 Nm

(4.4 ... 5.3 lbin)

8241 - 8246

4 mm

2 1)

0.5 ... 0.6 Nm

(4.4 ... 5.3 lbin)

3.4 Nm

(30 lbin)

-

(4.4 ... 5.3 lbin)

1)

With pin-end connector:

6 mm

2

With wire crimp cap:

4 mm

2

2)

With ring cable lug:

The cross-section is only limited by the cable cut-out in the housing.

Note!

-

Switching on the motor side of the controller is permitted

- for safety switch-off (emergency switch-off),

- under load.

Show/Hide Bookmarks