Application examples – Lenze 8200 Frequency inverters User Manual

Page 284

Application examples

8200SHB0199

15-5

Application FIG 15-2:

In a tank the water is to be held at a constant level. The speed of the pump must

be controlled depending on the amount of water delivered.

Functions used

-

Internal PID controller for level control.

- Regular control, analog setpoint input via terminal 8 with feedback via

analog channel E1 with plug-in module 8279IB.

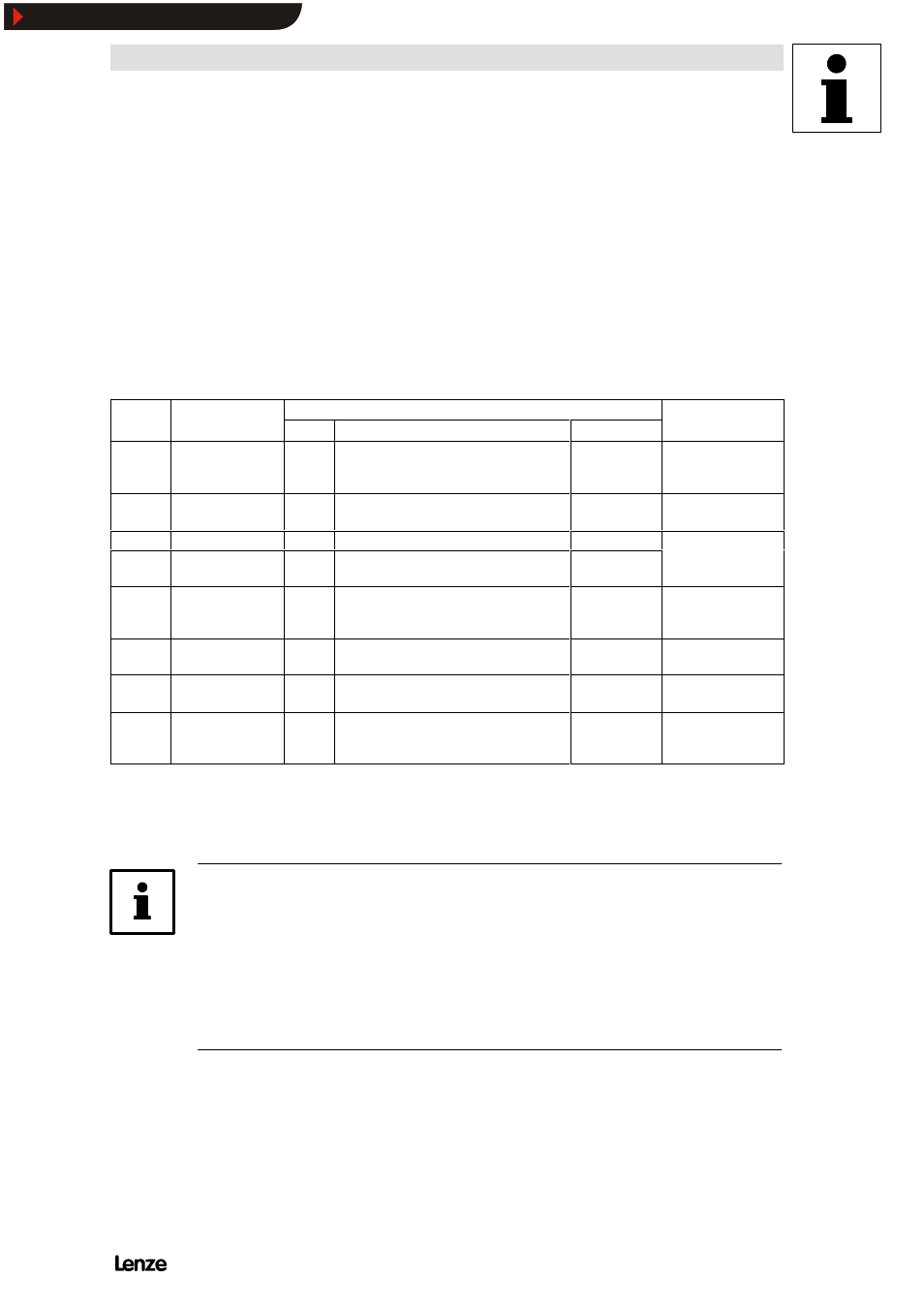

Code settings:

Code

Name

Possible settings

IMPORTANT

Code

Name

Lenze

Choice

Info

IMPORTANT

C005 Configuration

-0-

-6-

Operation with closed-loop control;

setpoint via terminal 8 with digital

frequency feedback via terminal E1

C007

¤ Terminal

configuration

-0-

-28- ... -45- or -48- ... -51-

Act. level value via

terminal E1

C070 Gain PID controller

1.00

0.02 ... 0.1

C071 Integral action time

PID controller

100

0.2 ... 1 s

Adaptation to process

C072 Differential

component of PID

controller

0.0

Inactive

C074 Influence PID

controller

0.0

100.0 %

C238

¤ Frequency

precontrol

-1-

-0-

No precontrol

C239

¤ Frequency setting

range

-0-

-1-

Unipolar

Direction of rotation

cannot be changed via

the process controller.

All other parameters are based on the factory setting.

Set the rated motor data under C088 (rated motor current) and C091 (motor cos

Ö) depending on the motor

connected.

Note!

-

Adapt C426 and C427 if the actual value input is 4 mA ... 20 mA.

(See chapter 3.7.1 and chapter 7.5.14.9)

-

Calibration of the setpoints and actual values to the application datum under

C500 and C501.

(See chapter 7.6.3)

Show/Hide Bookmarks