Commissioning – Lenze 8200 Frequency inverters User Manual

Page 127

Commissioning

8200SHB0199

5-22

Application FIG 5-3:

In a tank the water is to be held at a constant level. The speed of the pump must

be controlled depending on the amount of water delivered.

Functions used

-

Internal PID controller for level control.

- Regular control, analog setpoint selection via terminal 8 with feedback via

analog channel E1 with plug-in module 8279IB.

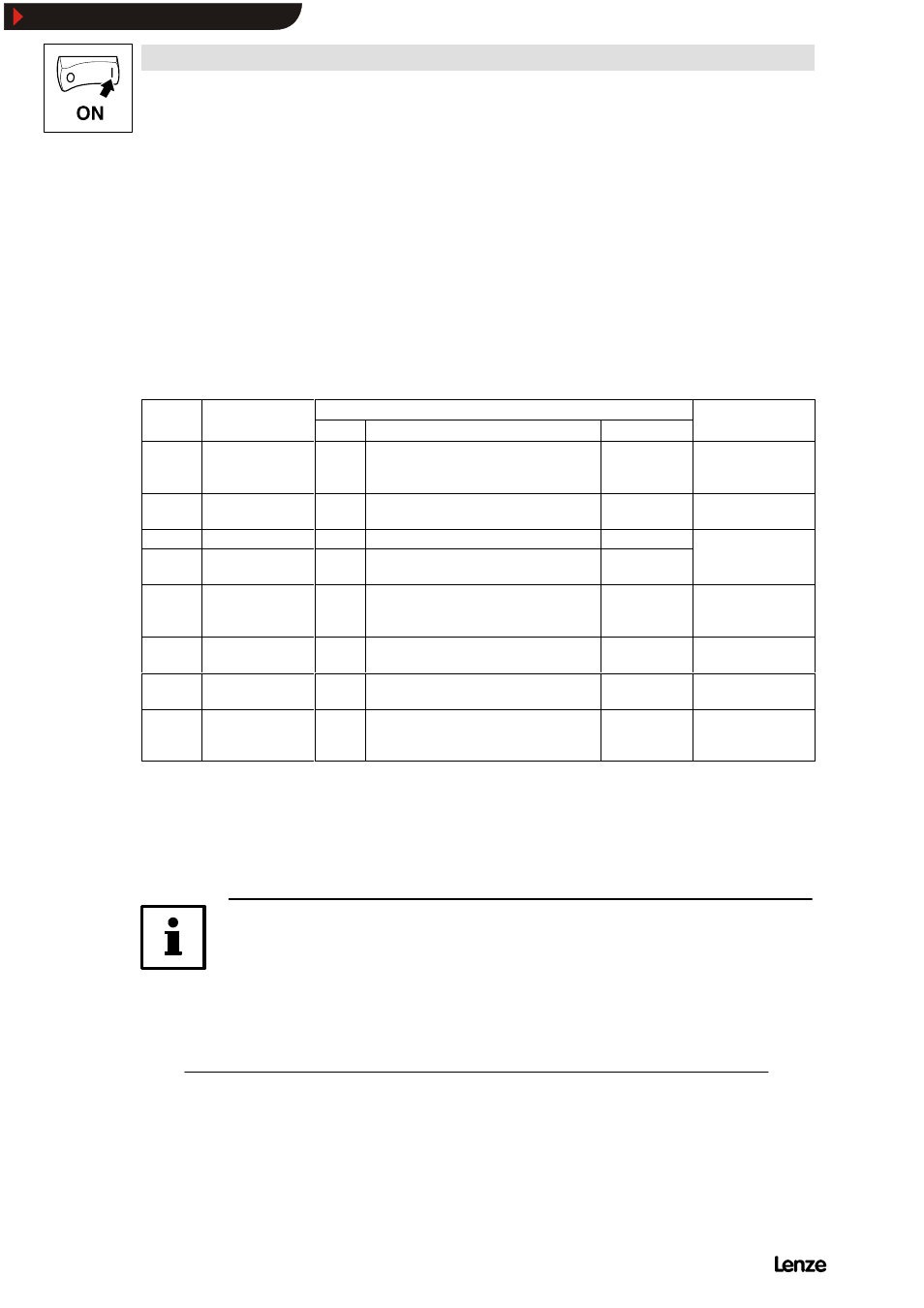

Code settings:

Code

Name

Possible settings

IMPORTANT

Code

Name

Lenze

Choice

Info

IMPORTANT

C005 Configuration

-0-

-6-

Operation with closed-loop control;

setpoint via terminal 8 with digital

frequency feedback via terminal E1

C007

¤ Terminal

configuration

-0-

-28- ... -45- or -48- ... -51-

Act. level value via

terminal E1

C070 Gain PID controller

1.00

0.02 ... 0.1

Adaptation to process

C071 Integral action time

PID controller

100

0.2 ... 1 s

Adaptation to process

C072 Differential

component of PID

controller

0.0

0

Inactive

C074 Influence PID

controller

0.0

100.0 %

C238

¤ Frequency

precontrol

-1-

-0-

No precontrol

C239

¤ Frequency setting

range

-0-

-1-

Unipolar

Direction of rotation

cannot be changed via

the process controller

-

All other parameters are based on the factory setting.

-

For the level setpoint observe the jumper setting at terminal 8 (see chapter 5.5.1).

Set 4 - 20 mA code C034 = 1.

-

Set the rated motor data under C088 (rated motor current) and C091 (motor cos

j) depending on the motor

connected.

Note!

-

Adapt C426 and C427 if the actual value input is 4 mA ... 20 mA.

(See chapter 3.7.1 and chapter 7.5.14.9).

-

Calibration of the setpoints and actual values to the application datum under

C500 and C501.

(See chapter 5.4.2.4).

Show/Hide Bookmarks