9 running optimisation, 1 slip compensation, Running optimisation – Lenze 8200 Frequency inverters User Manual

Page 165: Slip compensation, Configuration

Configuration

8200SHB0199

7-28

7.5.9

Running optimisation

7.5.9.1

Slip compensation

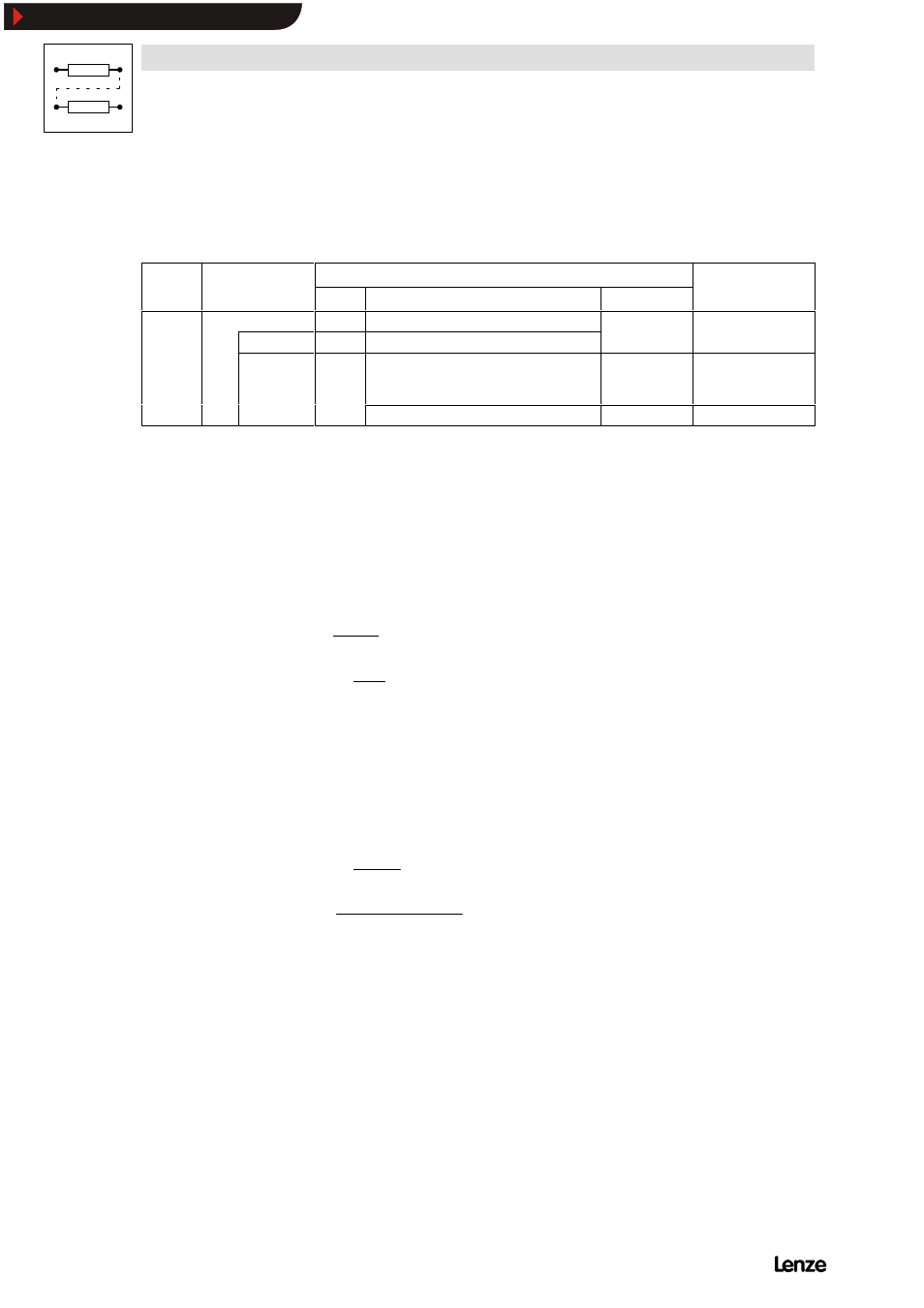

Code

Name

Possible settings

IMPORTANT

Lenze

Choice

Info

C021 Slip compensation

C021

820X

0.0

0.0

{0.1 %}

12.0

821X/822X/

824X

0.0

0.0

{0.1 %}

50.0

* With C014 = -2-,

-3-, controller

dependent

0.0

{0.1 %}

20.0

*With C014 = -4-

Function

Under load, the speed of an asynchronous machine is reduced. This load-dependent speed

reduction is called slip. The slip can be partly compensated by setting C021 accordingly. The slip

compensation is effective with all control modes (C014).

-

C021 < 0 (with C014 = -2-, -3-)

- “Smoother” drive characteristic, if strong load shock occur or application of several motors.

-

In the field frequency range between 5 Hz ... 50 Hz (87 Hz), the deviation of the rated speed is

$ 1 %(guide value). In field-weakening operation, the fault increases.

Adjustment

1.Rough setting of the slip constants (C021) by using the motor data:

Adjustment

s

n

Nsyn

Å n

r

n

Nsyn

ô 100 %

n

Nsyn

f

dr

ô 60

p

s

Slip constant (C021) [%]

n

Nsyn

Synchronous motor speed [min

-1

]

n

r

Rated speed to motor nameplate [min

-1

]

f

dr

Rated frequency to motor nameplate [Hz]

p

No. of pole pairs (1, 2, 3, ...)

2.Empirical precise setting of the slip compensation:

- Correct C021 until no load-dependent speed drop occurs in the required speed range between

idle running and max. motor load.

3.Example:

- Motor data: 4 kW / 1435 min

-1

/ 50 Hz

s

1500 min

Е1

Е1435 min

Å1

1500 min

Е1

ф 100 % 4.33 %

n

Nsyn

50 Hz

ô 60

2

1500 min

Å1

Preset C021 = 4.33 %

Important

If C021 is set too high, overcompensation can occur and lead to an instability of the drive.

Show/Hide Bookmarks