Commissioning – Lenze 8200 Frequency inverters User Manual

Page 118

Commissioning

8200SHB0199

5-13

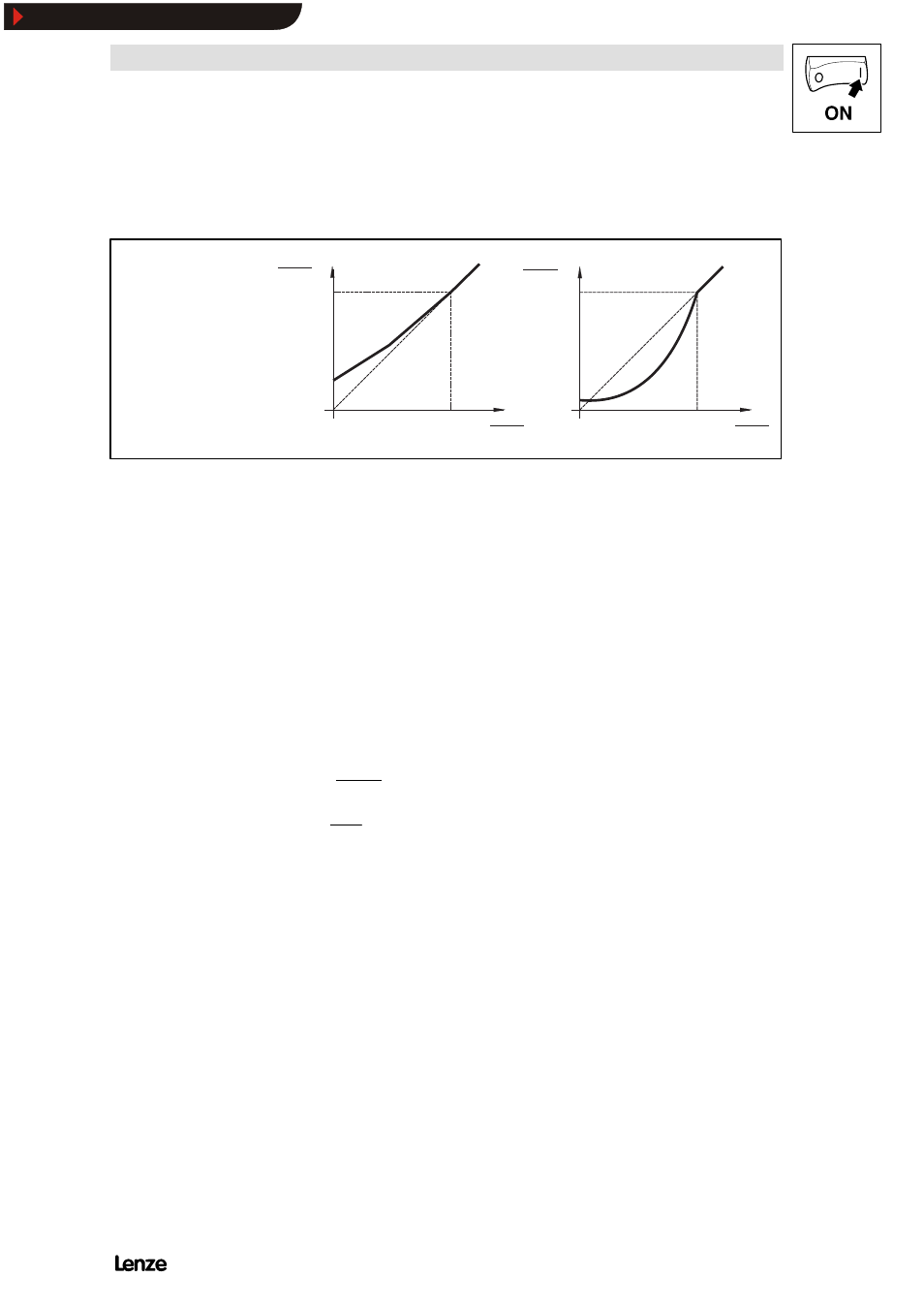

C014 = -2-

Linear characteristic

C014 = -3-

Square characteristic (e.g. for pumps, fans)

o u t

r m o t o r

V

V

1

V

m i n

0

0

1

C 0 1 5

f

d r m o t o r

o u t

r m o t o r

V

V

V

m i n

0

0

1

C 0 1 5

f

d r m o t o r

K 3 5 . 0 0 6 6 G B

3.Set V

min

boost (C016).

-

Load-independent boost of the motor voltage for field frequencies below the V/f-rated

frequency. It is thus possible to optimise the torque performance of the inverter drive.

-

It is absolutely necessary to adapt C016 to the asynchronous motor used. Otherwise the motor

may be overheated or the inverter may be operated with overcurrent.

Adjustment

Observe the thermal performance of the connected asynchronous motor at low field frequencies

when adjusting it:

-

Usually, self-ventilated standard asynchronous motors with insulation class B can be driven for a

short time with rated frequency with the frequency range between 0 Hz

f

d

25 Hz.

-

Contact the motor manufacturer for exact setting values for the max. permissible motor current in

the lower frequency range of self-ventilated motors.

A Operate the motor in idle running with f

d

slip frequency:

- P

mot

$7.5 kW: f

d

5 Hz

- P

mot

7.5 kW: f

d

2 Hz

Detect the slip frequency:

f

s

f

dr

ô

n

Nsyn

Å n

r

n

Nsyn

n

Nsyn

f

dr

ô 60

p

f

s

Slip frequency [Hz]

f

dr

Rated frequency to motor nameplate [Hz]

n

Nsyn

Synchronous motor speed [min

-1

]

n

r

Rated speed to motor nameplate [min

-1

]

p

No. of pole pairs (1, 2, 3, ...)

B Increase V

min

until the following motor current is reached:

- Motor in short-term operation at 0 Hz

f

d

25 Hz:

Self-ventilated motors:

I

motor

I

r motor

Forced-ventilated motors:

I

motor

I

r motor

- Motor in continuous operation at 0 Hz

f

d

25 Hz:

Self-ventilated motors:

I

motor

0.8 k I

r motor

Forced-ventilated motors:

I

motor

I

r motor

Show/Hide Bookmarks