Pf3000, Ag leader technology – Ag Leader PF3000 Harvest & Application Operators Manual User Manual

Page 133

PF3000

Calibrating Grain Weight

Ag Leader Technology

(Harvest Mode)

April 2002

3-17

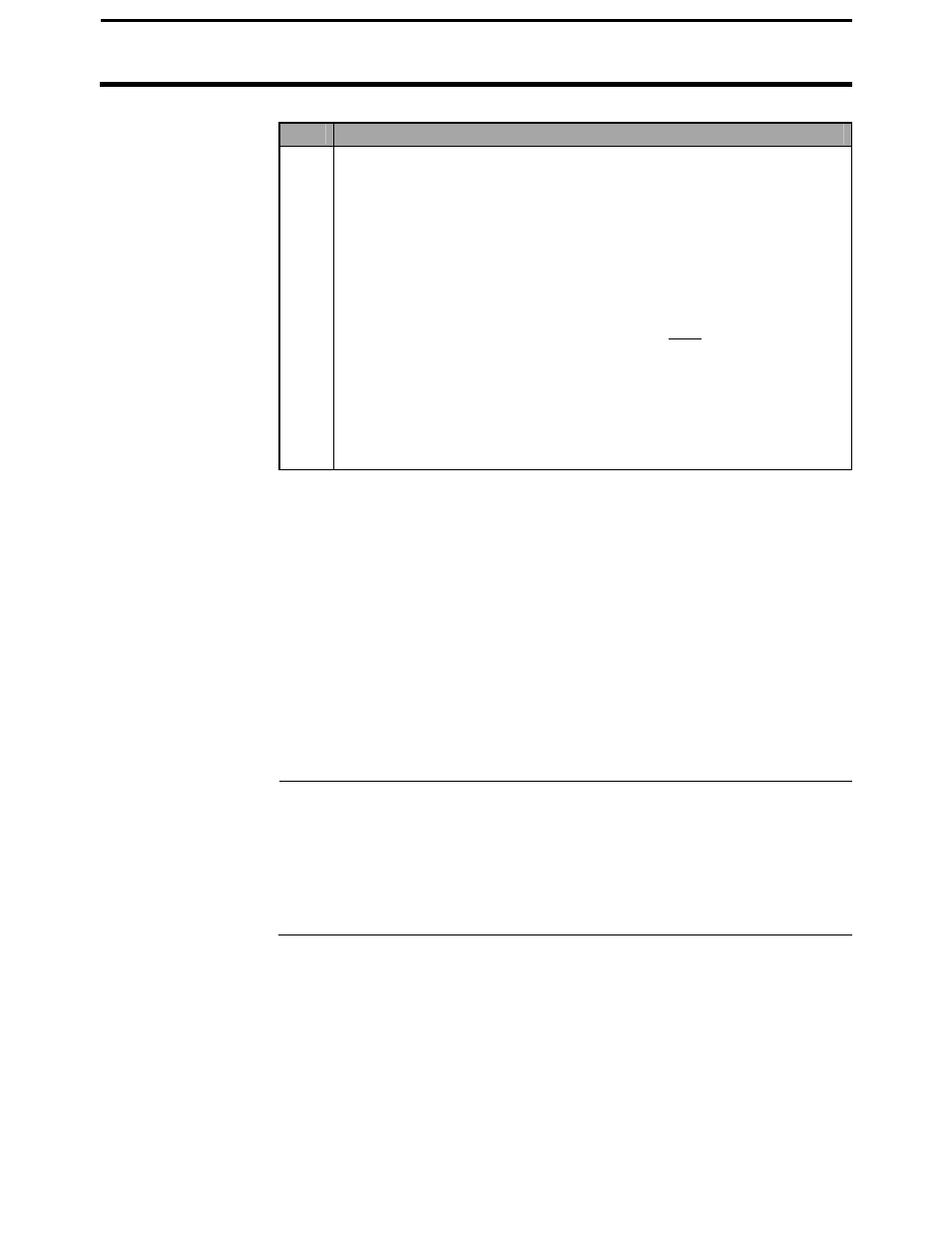

Step

Action

11

Good Calibration Results:

If you have four or more calibration loads for grain or one to three

calibration loads, your goal after completing a calibration should be

to achieve an average error of 1 percent to 3 percent and a

maximum error of 3 percent to 5 percent. If you have less than

four calibration loads, the calibration errors may be slightly higher

than if you had four or more calibration loads.

If you find loads with high calibration errors after completing a

calibration, you should remove the loads as calibration loads by

pressing the CAL ON/OFF key. Press the PERFORM CAL key

again to restart the calibration.

Once you are satisfied with your calibration results, press the EXIT

key until you return to the main operating screen.

Reasons for high calibration errors on loads

•

Grain type set incorrect for the load

•

Moisture is incorrect for the load

•

Actual pounds value is not correct

•

Grain weighed is not the same amount of grain that was harvested into

the load (for example: combine or wagon tank not empty before starting

load or forgot to change loads and added more grain into load after grain

weighed)

•

Did not have 1/2 inch clearance between paddles and elevator housing at

top of elevator

•

Installation problem with deflector plate or flow sensor

•

Elevator speed is erratic

Recalibrating the

Monitor

You can add or eliminate a calibration load and recalibrate the monitor any

time to improve the monitor’s calibration accuracy. If you have not achieved

satisfactory calibration results after entering 10 to 15 calibration loads (with

varied flow rates) something is wrong. Refer to the troubleshooting section

instead of adding more actual weights.