FEC FUSIONE-HS-2 User Manual

Page 98

Chapter 6: Fastening Instructions

6.1

Fastening Control.

The Fusion system is user programmable to select from two different fastening methods, r

ferred to as Torque Control and Angle Control methods.

formed in 1 to 3 incremental step

fied torque or angle values.

NOTE: All setting recommendations are based upon common fasten

Applications that experience high Prevailing torque, excessive joint compre

other unique characteristics must be set

6.1.1 Torque Control Method.

In Torque Control method, fastening is performed based upon attaining a desired torque va

ue within one to three incremental steps, whil

the fastener and time. Additional monitor items (limits) can be set to enhance the systems

ability to determine if the fastener was properly secured

One-Step Fastening

One-step fastening will be used primarily for joints which have no requirement to synchronize

with another spindle during the final stage of the rundown.

Plugs, single spindle applications.

1. Once SPEED CHANGE TORQUE is reached

tem will switch from FREERUN

1ST TORQUE.

2. The system will fasten to the 1ST TORQUE value during the specified 1ST TIME. 1ST

TORQUE must be reached within the 1ST TIME limits or a reject wi

3. Upon reaching 1ST TORQUE, 1ST TIME ends and FINAL TIME begins. 1ST TORQUE is

the shift point to TORQUE SPEED

4. The system will fasten to STANDARD TORQUE

STANDARD TORQUE must be reached within the FINAL T

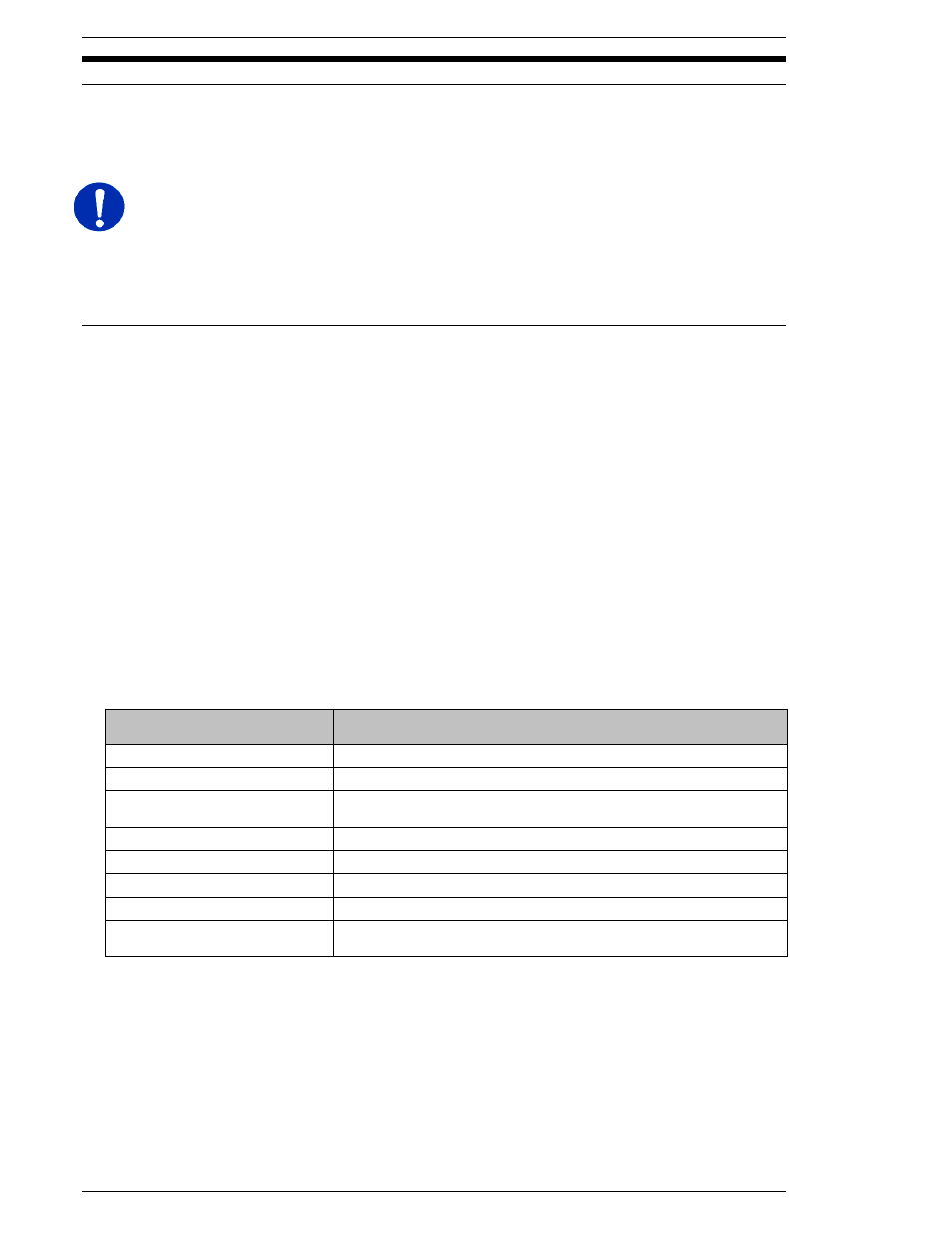

FUNCTION

RECOMMENDATION

SPEED CHANGE TORQUE

10% of STANDARD TORQUE

THRESHOLD TORQUE

Start point of 1

1ST TORQUE

30% of STANDARD TORQUE

Used for RATE/TIME settings

SNUG TORQUE

Angle Monitoring Start Point

CROSSOVER TORQUE

Start point of 3

STANDARD TORQUE

Engineered product fastening specification

1ST TIME HIGH/LOW LIMIT

Acceptance

FINAL TIME HIGH/LOW LIMIT Acceptance range to go from 1ST TORQUE to STANDARD

TORQUE

Page 6-2

is user programmable to select from two different fastening methods, r

ferred to as Torque Control and Angle Control methods. Each control method can be pe

ntal steps, which will successively secure the fastener to the spec

NOTE: All setting recommendations are based upon common fastening applications.

Applications that experience high Prevailing torque, excessive joint compression or

other unique characteristics must be set with these characteristics in mind.

In Torque Control method, fastening is performed based upon attaining a desired torque va

ncremental steps, while monitoring the degrees of rotation (Angle) of

and time. Additional monitor items (limits) can be set to enhance the systems

ability to determine if the fastener was properly secured (Section 6.2).

be used primarily for joints which have no requirement to synchronize

with another spindle during the final stage of the rundown. Examples: Pipe Plugs, Spark

Plugs, single spindle applications.

Once SPEED CHANGE TORQUE is reached or FREERUN REVOLUTIONS expires

tem will switch from FREERUN SPEED to SLOWDOWN SPEED and continue to fasten to

The system will fasten to the 1ST TORQUE value during the specified 1ST TIME. 1ST

TORQUE must be reached within the 1ST TIME limits or a reject will occur.

Upon reaching 1ST TORQUE, 1ST TIME ends and FINAL TIME begins. 1ST TORQUE is

the shift point to TORQUE SPEED.

The system will fasten to STANDARD TORQUE using TORQUE SPEED during FINAL TIME.

STANDARD TORQUE must be reached within the FINAL TIME limits or a reject will occur.

RECOMMENDATION / COMMENT

10% of STANDARD TORQUE

Start point of 1

st

torque rate monitoring (section 6.2)

30% of STANDARD TORQUE

Used for RATE/TIME settings and TORQUE SPEED initiation.

Angle Monitoring Start Point (section 6.2)

Start point of 3

RD

torque rate monitoring (section 6.2)

Engineered product fastening specification

Acceptance range to reach 1ST TORQUE setting

Acceptance range to go from 1ST TORQUE to STANDARD

TORQUE

is user programmable to select from two different fastening methods, re-

ach control method can be per-

which will successively secure the fastener to the speci-

applications.

ssion or

In Torque Control method, fastening is performed based upon attaining a desired torque val-

e monitoring the degrees of rotation (Angle) of

and time. Additional monitor items (limits) can be set to enhance the systems

be used primarily for joints which have no requirement to synchronize

Examples: Pipe Plugs, Spark

xpires, the sys-

and continue to fasten to

The system will fasten to the 1ST TORQUE value during the specified 1ST TIME. 1ST

Upon reaching 1ST TORQUE, 1ST TIME ends and FINAL TIME begins. 1ST TORQUE is

using TORQUE SPEED during FINAL TIME.

IME limits or a reject will occur.

and TORQUE SPEED initiation.

Acceptance range to go from 1ST TORQUE to STANDARD