4 nutrunner (tool) dimensions, 1 straight tool – FEC FUSIONE-HS-2 User Manual

Page 43

FEC FUSION Operations Manual

Chapter 4: System Setup and Wiring (Rev. 2.1)

Page 4-5

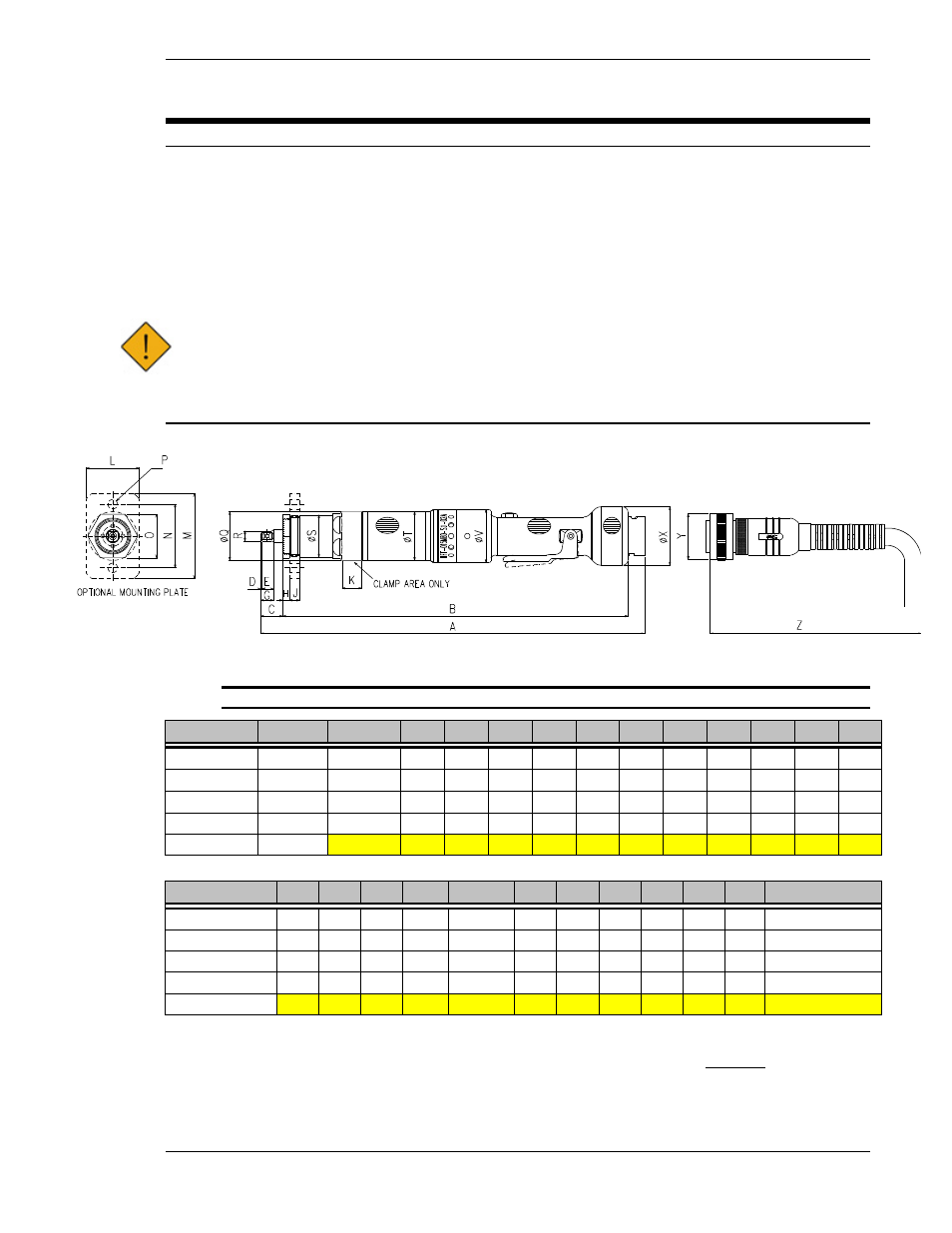

4.4 Nutrunner (Tool) Dimensions

Tool dimensions and mounting specifications are critical in determining the design of the sus-

pension / reaction equipment required for the tool assemblies. Provide adequate clearance to

ensure that the tool assemblies do not come in contact with any object. Failure to provide

adequate clearance may result in torque inaccuracies in the monitoring capability of the sys-

tem, possible damage to the tool assembly, or operator injury.

Customer specific ergonomic guidelines and preferred supplier lists should be used in deter-

mining suspension / reaction equipment requirements

WARNING:

Torque tools generate large amounts of torque that can cause injury when

held in the hand of an operator. Be sure all precautions are taken to ensure torque

reaction devices are installed to absorb or suppress reaction torque from operators!

4.4.1 Straight Tool

FIG. 4-4-1 Straight Tool (dimensions in mm)

HFT-TYPE

N

O

P

Q

R

S

T

V

X

Y

Z

WEIGHT

010M50-S1

60

41 9 (2)

46 9.5 (.375) 40

46

50

55

43

230

1.3Kg(2.8lb)

015M80-S1

60

41 9 (2)

46 9.5 (.375) 40

46

50

55

43

230

1.4 Kg(3.2lb)

025M80-S1

60

41 9 (2)

46 9.5 (.375) 40

46

50

55

43

230

1.4 Kg(3.2lb)

040M80-S

60

41 9 (2)

46 9.5 (.375) 40

46

50

55

43

230

1.4 Kg(3.2lb)

080M80-S

T

B

A

Mounting: Tool may be mounted by using a clamp collar located in the area shown in the

drawing above. Tolerance for diameter of inside of clamp must be +0.1 to +0.2

of dimension shown as the “clamping area”.

Note: Dimensions shown are subject to change without warning due to design improvements.

HFT-TYPE

TORQUE

SPEED

A

B

C

D

E

G

H

J

K

L

M

010M50-S1

1.0KgM

1800

rpm

343 306

21

1.5 10.6 12.1

6

10

18

50

80

015M80-S1

1.5KgM

1665

rpm

363 326

21

1.5 10.6 12.1

6

10

18

50

80

025M80-S1

2.5KgM

900 rpm 363 326

21

1.5 10.6 12.1

6

10

18

50

80

040M80-S

4.0KgM

694

rpm

363 326

21

1.5 10.6 12.1

6

10

18

50

80

080M80-S

8.0KgM

T

B

A