FEC FUSIONE-HS-2 User Manual

Page 72

Chapter 4: System Setup and Wiring

Page 4-34

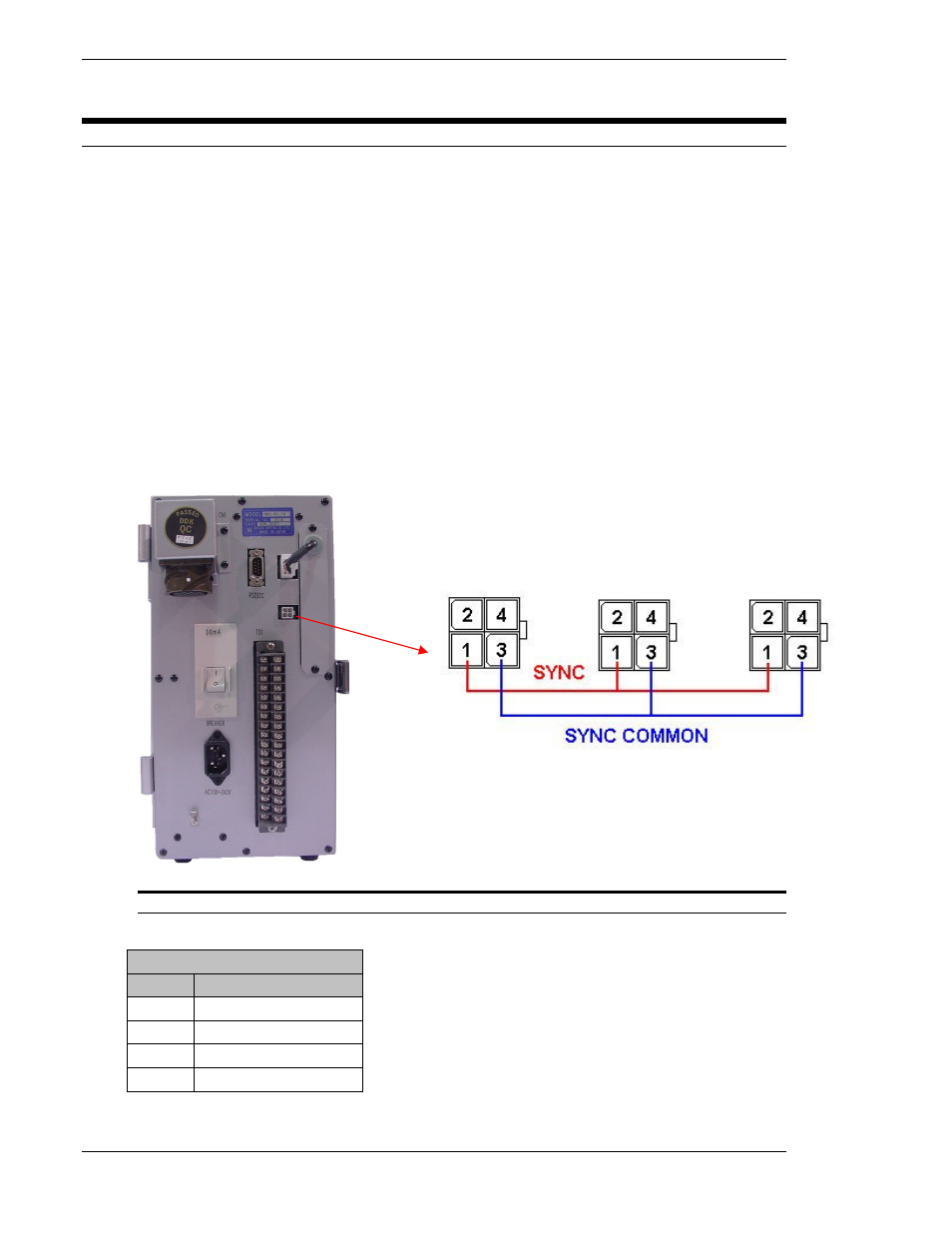

4.13 SYNC Connector

The Sync connector is provided for a means to synchronize more than one spindle during the

fastening process. Synchronized fastening allows spindles to synchronize at a preset torque

before attempting to reach the next target or final torque. For synchronized fastening opera-

tion using individual Fusion controllers, the SYNC terminals must be wired between all af-

fected spindles.

The SYNC signals are Bi-directional signals for synchronized fastening (5V, TTL signal).

1. At the start of the cycle until reaching the synchronization point (1st torque), the SYNC

signal is ON (LOW condition) to stop other Fusion Units from continuing to the second

step (wired OR).

2. When the 1st torque is reached, the signal works as an input signal. If it reads LOW -

meaning that other Fusion units have not reached 1st torque yet - the Fusion unit stays in

the standby state waiting for all connected spindles to reach first torque.

When the SYNC signal is HIGH (all Fusion units have completed the first step), all units si-

multaneously start the second step.

Fig. 4.13 Sync Connector

CN6 (Sync Connector)

PIN

DESCRIPTION

1

Sync Signal (5V TTL)

2

Not Used

3

Sync Common (0v)

4

Frame Ground (FG)

Spindle SYNC signals are connected in series from

one spindle to the next.